Method for determining mineral aggregate gradation by using three control points hyperbolic structure

A technology for determining methods and control points, applied in chemical instruments and methods, grading, analyzing materials, etc., can solve the problems of not fully reflecting the gradation characteristics of raw materials and mineral materials, and small room for grading selection, and achieve clear and rapid grading optimization. selected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail below in conjunction with the embodiments.

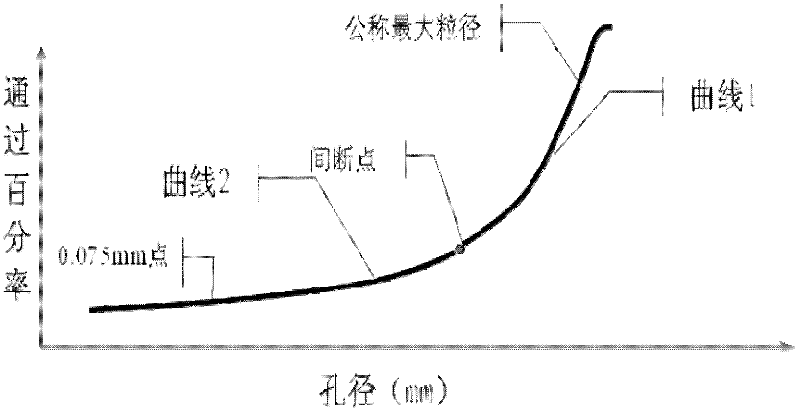

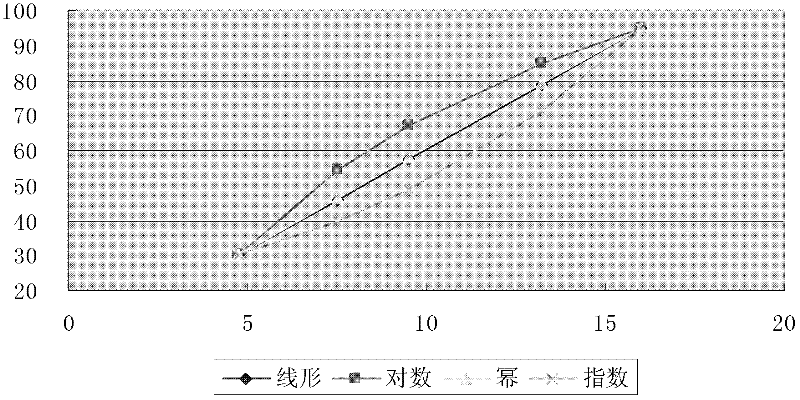

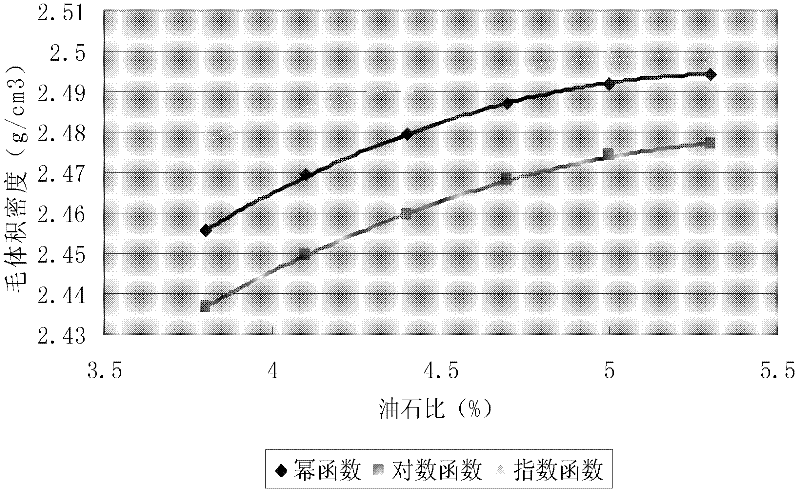

[0070] This experiment takes 16-type mixture as an example, adopts the principle of skeleton break gradation, the pass rate of 16mm is 95%, the pass rate of 4.75mm is 30%, and the pass rate of 0.075mm is 7%. These three points are used as control points. The fine aggregate grading curve is calculated and generated by logarithmic function, power function and exponential function. According to the orthogonal experiment, the curves of different fine aggregates and coarse aggregates can be determined. In this technical scheme, only the influence of the change of the proportion of the coarse aggregate on the various indicators and performance is considered, and the fine aggregates of 4.75mm~0.075mm are unified Use power function generation. Establish fine aggregate gradation curve; 16mm~4.75mm coarse aggregate adopts logarithmic function model, power function model and expone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com