Method for obtaining active polypeptide by carrying out multi-strain compound solid state fermentation on common rapeseed meal

A solid-state fermentation, active polypeptide technology, applied in protein food processing, plant protein processing, food science and other directions, can solve the problems of expensive enzymes and unfavorable promotion, and achieve low drying energy consumption, no environmental pollution, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

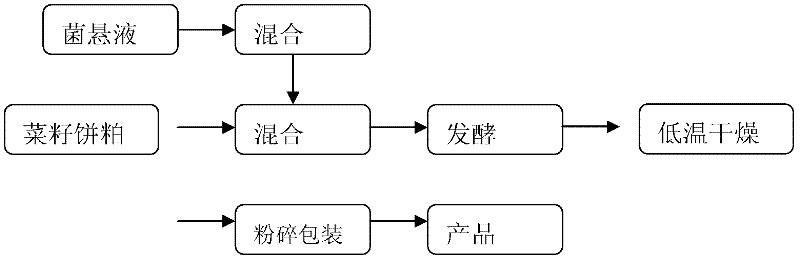

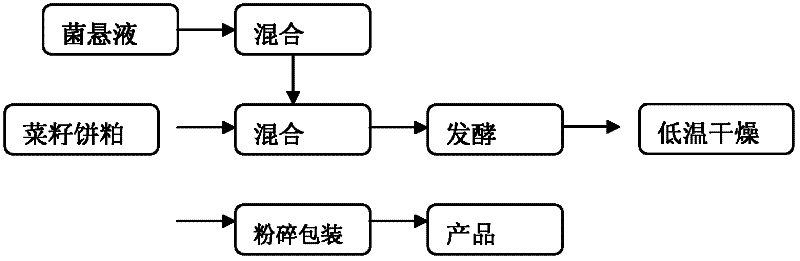

Method used

Image

Examples

Embodiment 1

[0020] 1) Inoculate according to the ratio of plant lactic acid bacteria: Bacillus subtilis: Aspergillus oryzae = 3: 2: 1, and the concentration of the inoculated bacterial suspension is 10 8 / mL, the liquid-solid ratio is 9%, 6% and 3% respectively;

[0021] 2) After inoculating the rapeseed meal, place it in a fermentation tank for fermentation, the fermentation conditions: pH value 6.0, water-material ratio 0.6:1, temperature 25°C, fermentation time 72h;

[0022] 3) drying the fermented rapeseed meal at 55°C to obtain the active polypeptide.

[0023] It was detected that the crude protein content in rapeseed meal increased by 5% compared with that before fermentation, and the polypeptide content increased by more than 4.2% compared with before fermentation. 8-fold increase in DPPH clearance.

Embodiment 2

[0025] 1) Inoculate according to the ratio of plant lactic acid bacteria: Bacillus subtilis: Aspergillus oryzae = 2: 3: 1, and the concentration of the inoculated bacterial suspension is 10 8 / mL, the liquid-solid ratio is 6%, 9% and 3% respectively;

[0026] 2) After the rapeseed meal is inoculated, it is placed in a fermentation box for fermentation, the fermentation conditions are: pH value 5.5, water-material ratio 0.9:1, temperature 35°C, fermentation time 100h;

[0027] 3) drying the fermented rapeseed meal at 55°C to obtain the active polypeptide.

[0028] It was detected that the crude protein content in rapeseed meal increased by 8.7% compared with that before fermentation, and the polypeptide content increased by 5.1% compared with that before fermentation. 10-fold increase in DPPH clearance.

Embodiment 3

[0030] 1) Inoculate according to the ratio of plant lactic acid bacteria: Bacillus subtilis: Aspergillus oryzae = 1: 1: 3, and the concentration of the inoculated bacterial suspension is 10 8 / mL, the liquid-solid ratio is 3%, 3% and 9% respectively;

[0031] 2) After the rapeseed meal is inoculated, it is placed in a fermentation box for fermentation, the fermentation conditions are: pH value 6.5, water-material ratio 1.2:1, temperature 30°C, fermentation time 120h;

[0032] 3) drying the fermented rapeseed meal at 55°C to obtain the active polypeptide.

[0033] It was detected that the crude protein content in rapeseed meal increased by 6.4% compared with that before fermentation, and the polypeptide content increased by 4.1% compared with that before fermentation. 9-fold increase in DPPH clearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com