Concrete water evaporation inhibitor with shrinkage function and preparation method thereof

An evaporation inhibitor and concrete technology, applied in the field of concrete, can solve the problems of high price of admixtures and limited promotion, and achieve the effects of reducing the risk of shrinkage cracking, improving durability and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

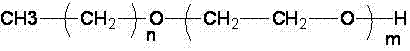

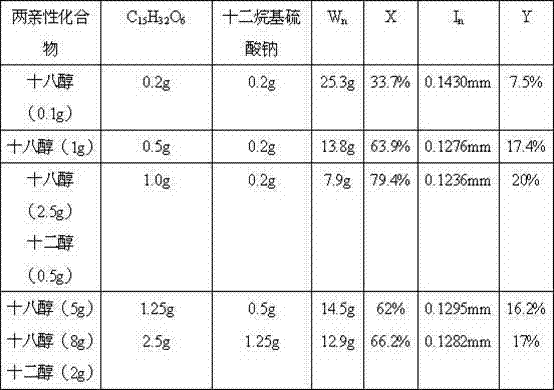

[0033] Amphiphilic compounds, nonionic surfactants with the function of reducing concrete shrinkage: C 15 h 32 o 6

[0034] (n=4, m=5), anionic surfactant: sodium lauryl sulfate, mixed with water at 80°C (total weight 100g), stirred evenly for 30 minutes, and discharged. The prepared emulsion was diluted 10 times and sprayed on the surface of plastic concrete to test its efficiency of reducing water evaporation and the ratio of inhibiting concrete shrinkage. The ratio of each component and the experimental results are shown in Table 1.

[0035] Table 1 The content of each component and the efficiency of reducing water evaporation and inhibiting concrete shrinkage ratio

[0036]

Embodiment 6-10

[0038] Mix 4g stearyl alcohol, 1g lauryl alcohol, a certain amount of non-ionic surfactant and anionic surfactant that can reduce the shrinkage of concrete, mix with water (total weight is 100g) at 80°C, and stir evenly for 30 minutes. Discharge. The prepared emulsion was diluted 10 times and sprayed on the surface of plastic concrete to test its efficiency of reducing water evaporation and the ratio of inhibiting concrete shrinkage. The ratio of each component and the experimental results are shown in Table 2.

[0039] Table 2 The content of each component and the efficiency of reducing water evaporation and inhibiting concrete shrinkage ratio

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com