Regeneration method of waste lubricating oil

A technology of waste lubricating oil and lubricating oil, which is applied in the direction of lubricating composition, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of complex composition, many types of waste lubricating oil raw materials, and affecting the normal operation of the process, and achieves simple and large-scale Social benefits and economic benefits, and the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The properties of waste lubricating oil used in this embodiment are shown in Table 1.

[0021] 10kg of waste lubricating oil is processed through the following steps:

[0022] (1) Pretreatment

[0023] Put the waste lubricating oil in a mixer with stirring, stir at 60°C for 20 minutes, then move it into a settling tank for 10 hours to remove moisture and mechanical impurities;

[0024] (2) Rectification:

[0025] Filter the waste oil pretreated in step (1) and enter the rectification tower under operating conditions: the temperature is 150-170°C, and the vacuum degree is 240-260Pa;

[0026] (3) Short path distillation

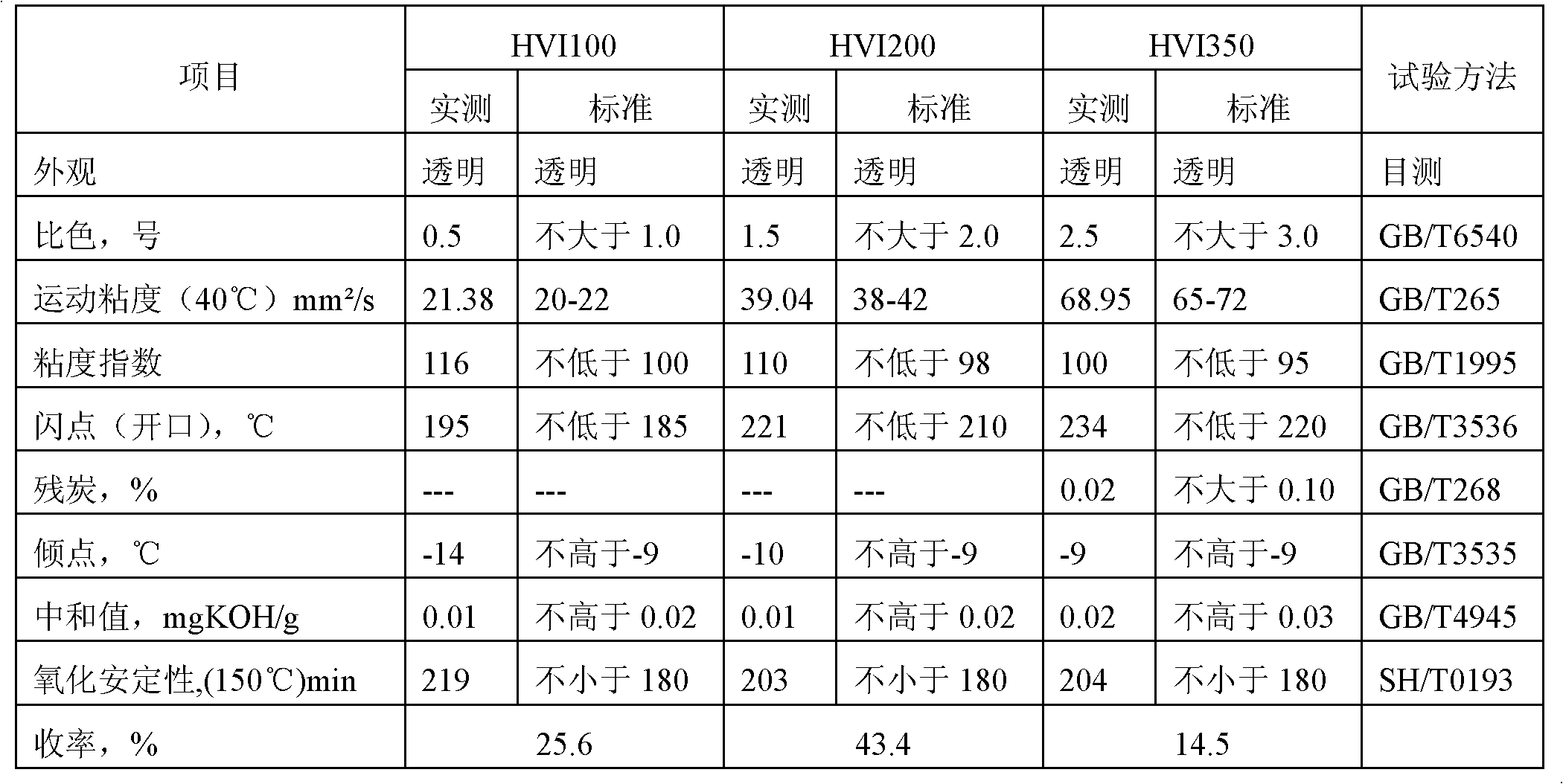

[0027] The waste oil treated in step (2) enters short-path distillation, and undergoes the following three stages of distillation in turn: the operating conditions of the first-stage short-path distillation are temperature 170-200°C, vacuum degree 30-50Pa, and light lubricating oil base stock is fractionally distilled; then The material enters the se...

Embodiment 2

[0037] The used lubricating oil properties of this embodiment are shown in Table 3.

[0038] 10kg of waste lubricating oil is processed through the following steps:

[0039] (1) Preprocessing:

[0040] The waste lubricating oil is placed in a mixer with agitation, and 0.5-1.0% of the weight of the waste lubricating oil is added in mixed ethyleneamine with a nitrogen content of 40-41%. Stir at 90°C for 40 minutes, then move into a settling tank for 10 hours to remove moisture and impurities.

[0041] (2) Distillation:

[0042] The waste oil pretreated in step (1) is filtered and then enters the rectification tower. The operating conditions are: the temperature is 150-170°C, and the vacuum degree is 250-260Pa.

[0043] (3) Short path distillation:

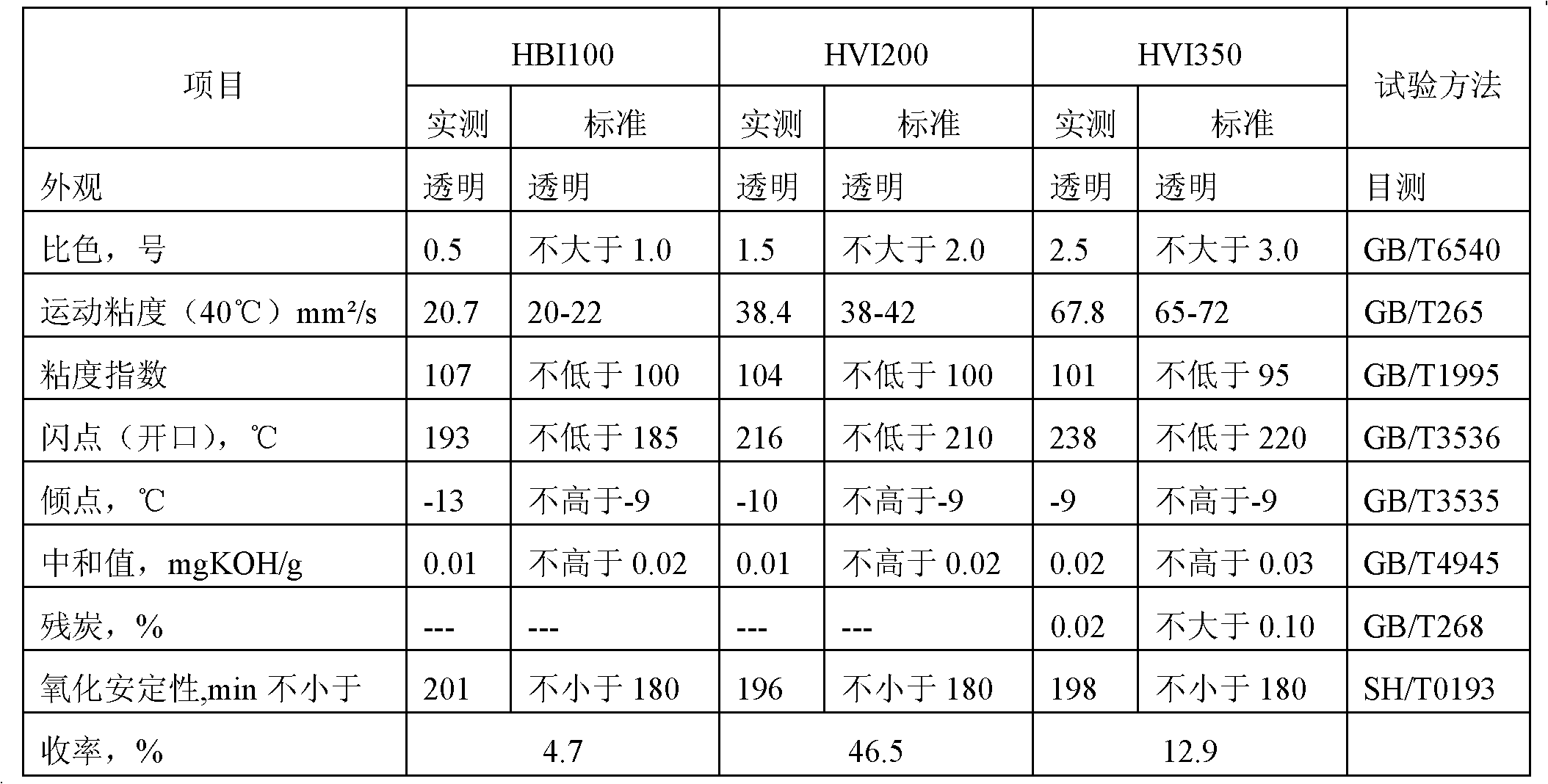

[0044] Put the waste oil treated in step (2) into short-path distillation, and then undergo the following three stages of distillation: the operating conditions of the first-stage short-path distillation are temperature 170-200°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com