Flexible energy-consumption frame filling wall

A technology for infilling walls and frames, applied in the directions of walls, building components, and anti-seismic, can solve the problems of sudden stiffness, shear failure of short columns, and increased horizontal seismic force, so as to achieve fast and convenient installation, reduce seismic response, and reduce manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

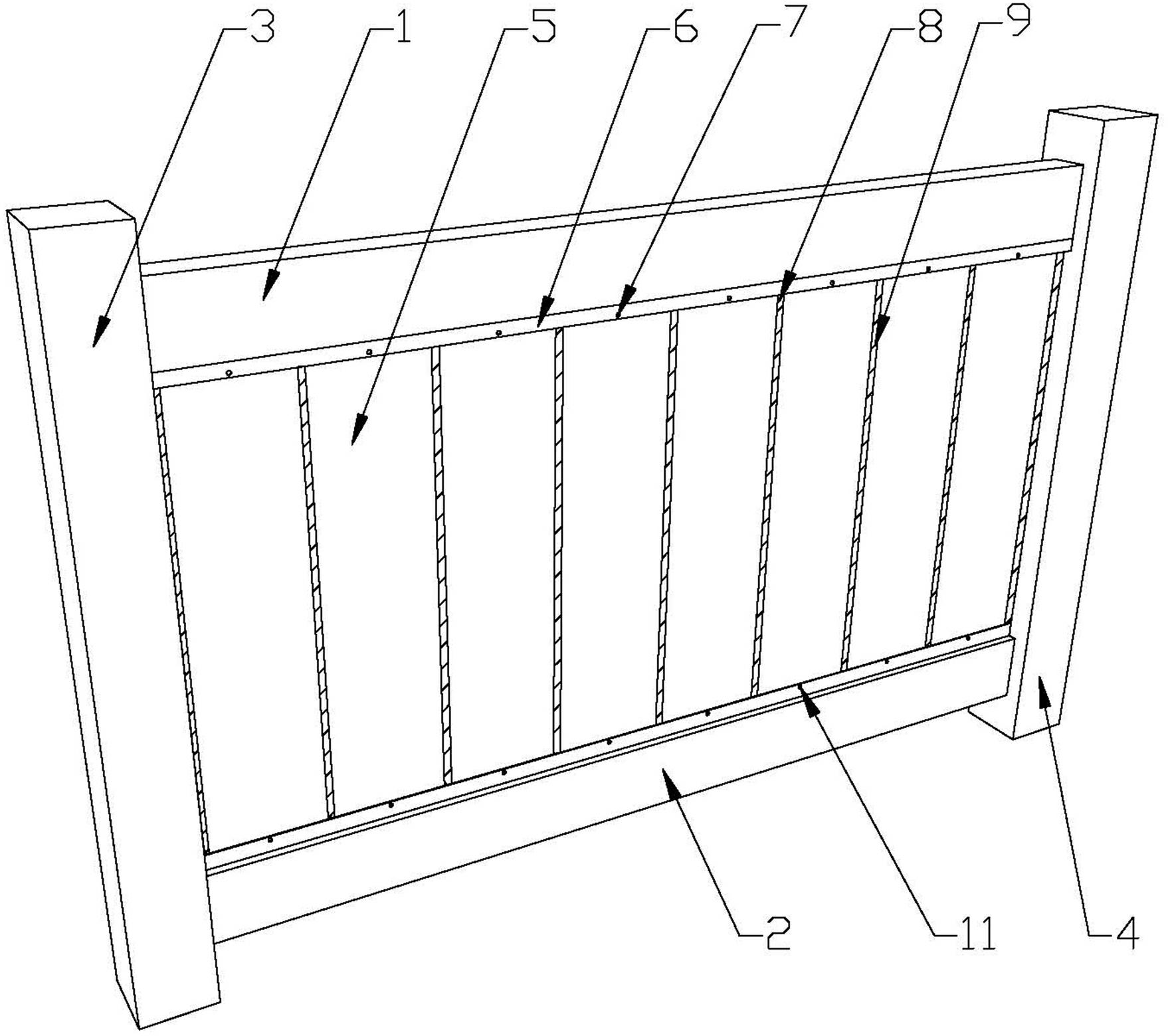

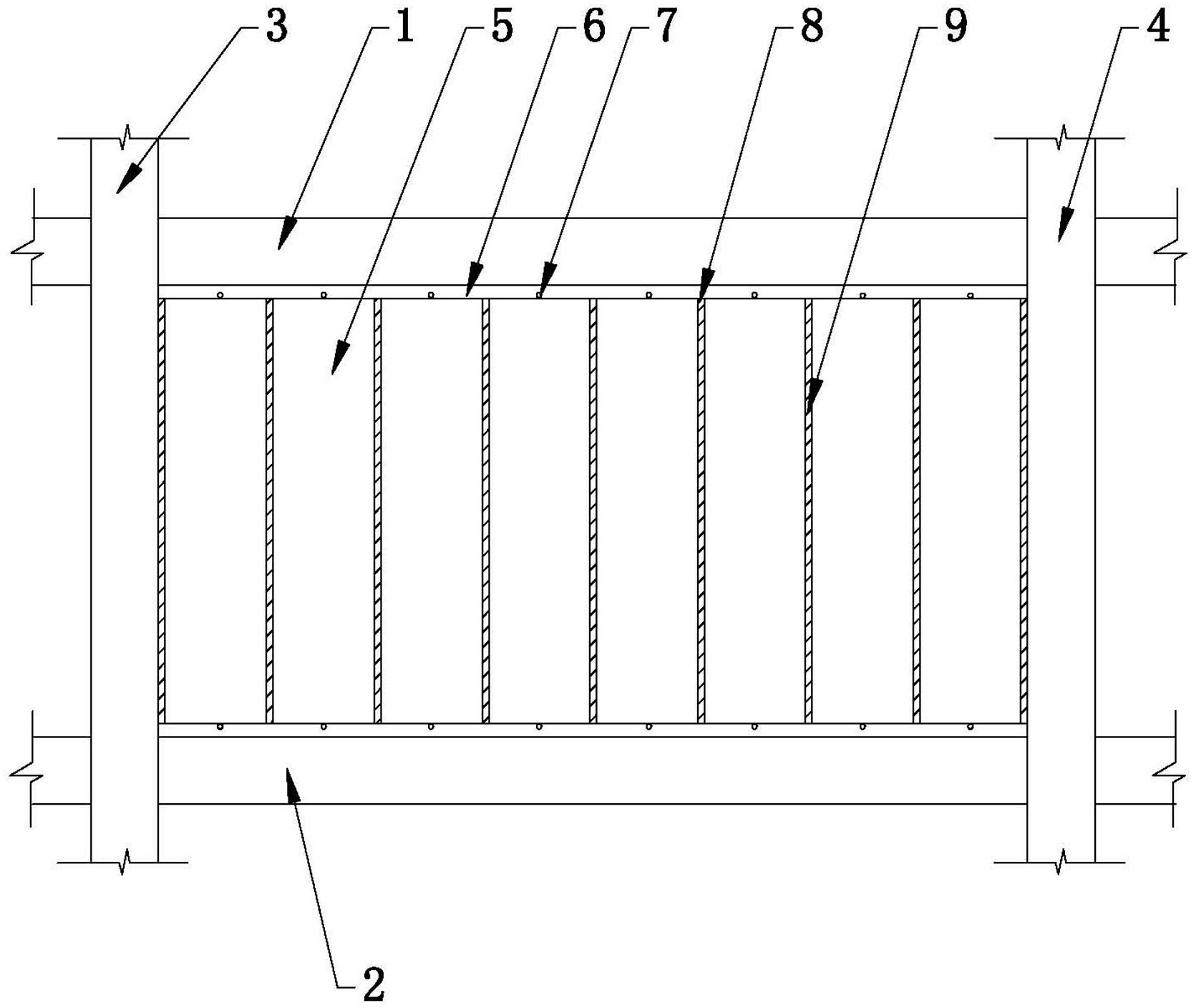

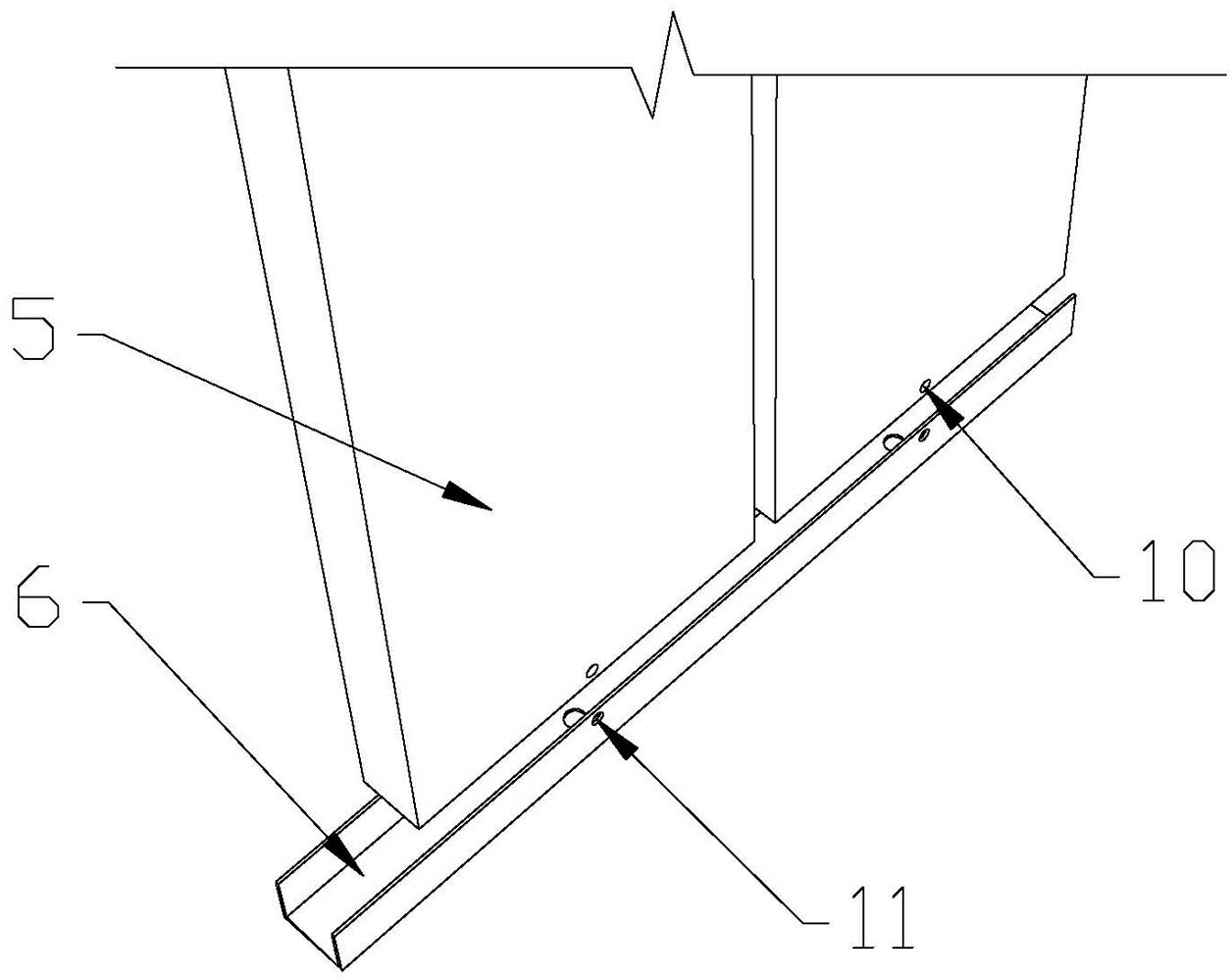

[0028] Such as Figure 1-5 Shown: a flexible energy-dissipating frame filled wall, including the upper frame beam 1, the lower frame beam 2, the left frame column 3 and the right frame column 4 and the partition wall strip 5, the upper frame beam 1, the lower frame beam The frame beam 2, the left frame column 3 and the right frame column 4 are concrete frames or steel frames, and the partition wall strips 5 include autoclaved aerated concrete strips, industrial ash concrete porous strips, and glass fiber reinforced cement lightweight porous strips board, gypsum slats, plant fiber slats, fly ash foam cement slats and silicon magnesium aerated cement slats. In the lower side of the beam bottom of the upper frame beam 1 and the upper side of the beam top of the lower frame beam 2 opposite to it, there are respectively fixed U-shaped steel plate grooves 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com