LED automobile headlamp light source and manufacturing method thereof

The invention relates to a technology for automobile headlights and a manufacturing method, which is applied in the field of LED automobile headlight sources and the production field of LED automobile headlight sources, which can solve the problems of immature headlights and the like, and achieve the effect of good light distribution effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

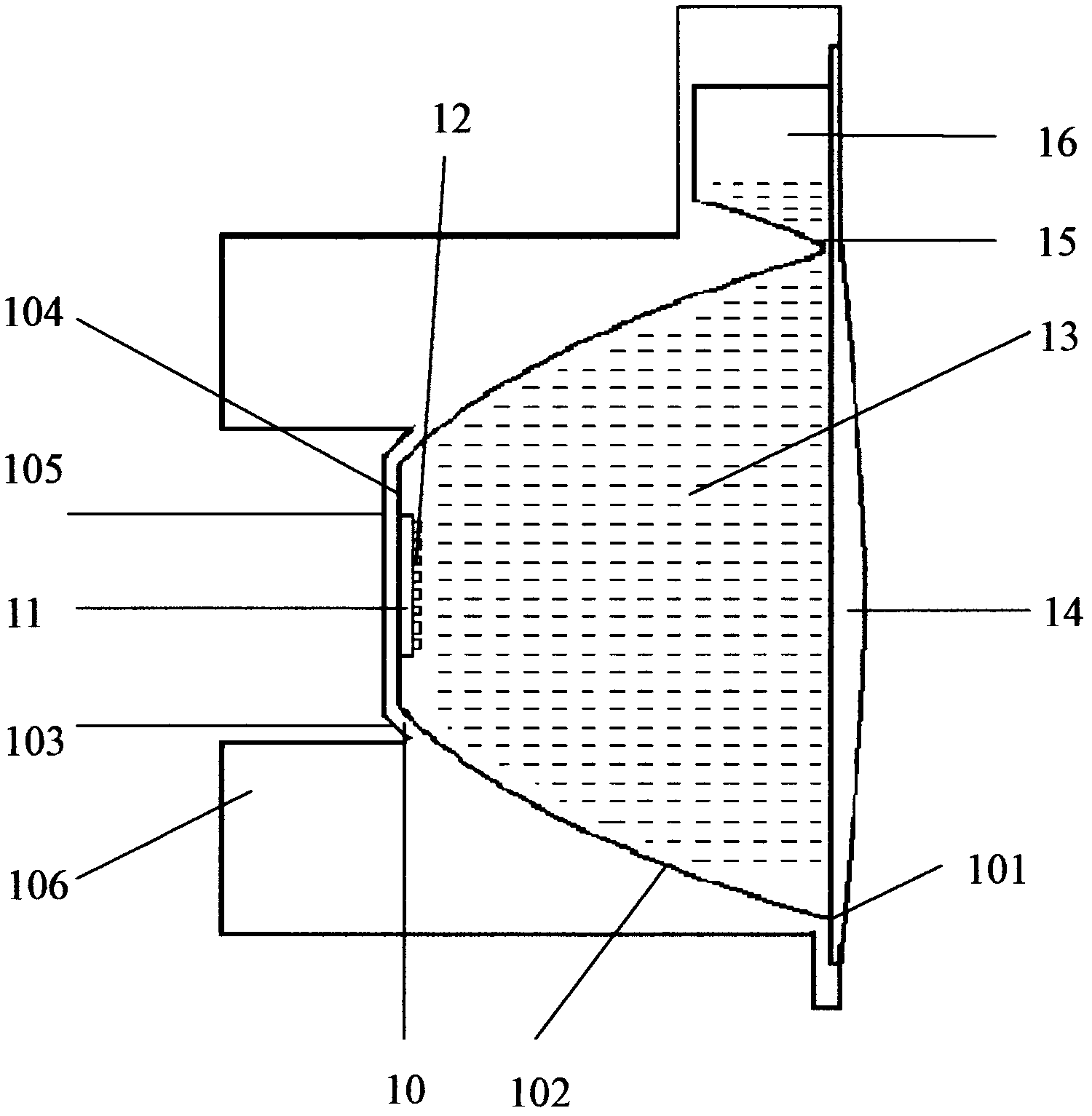

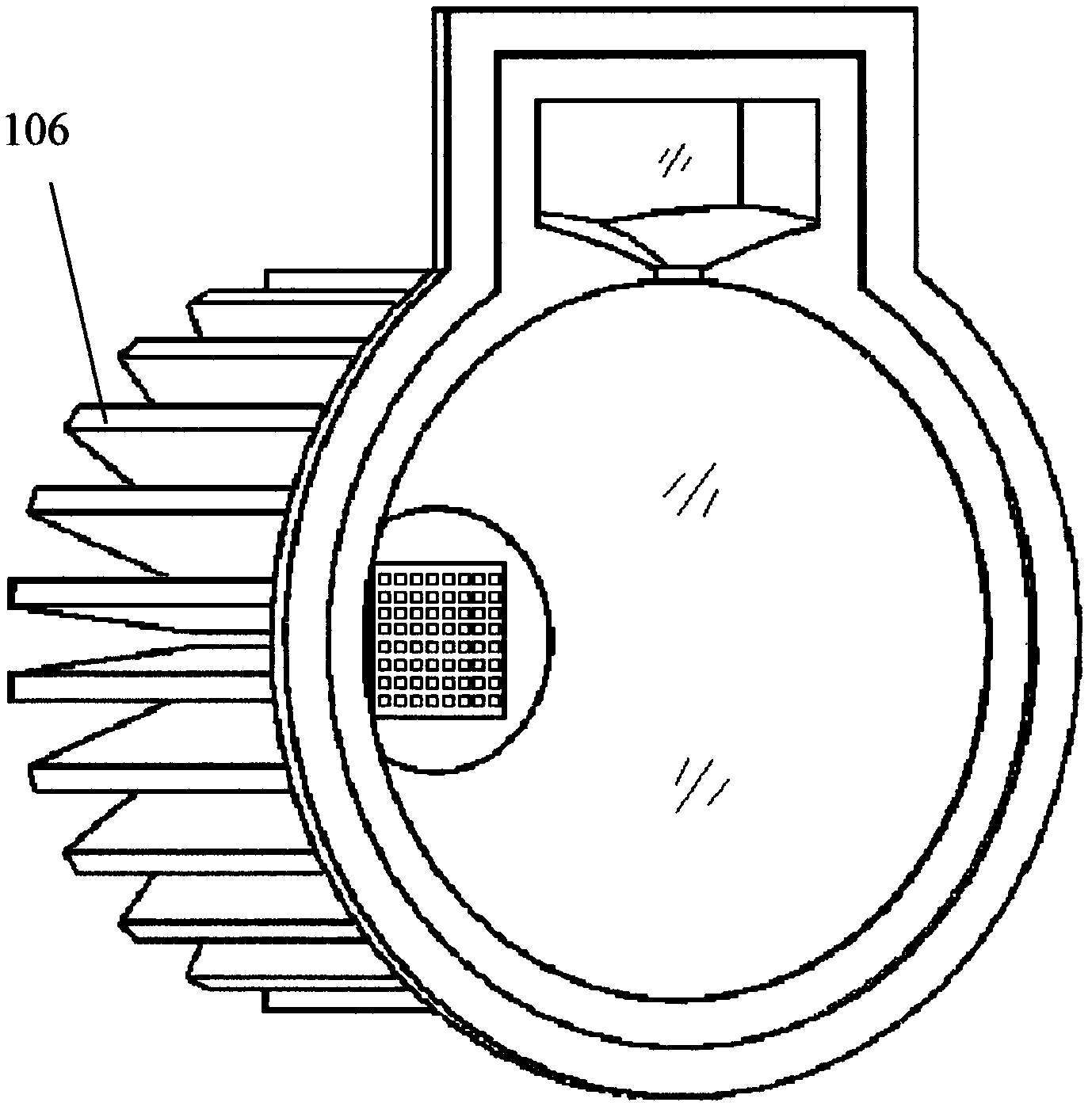

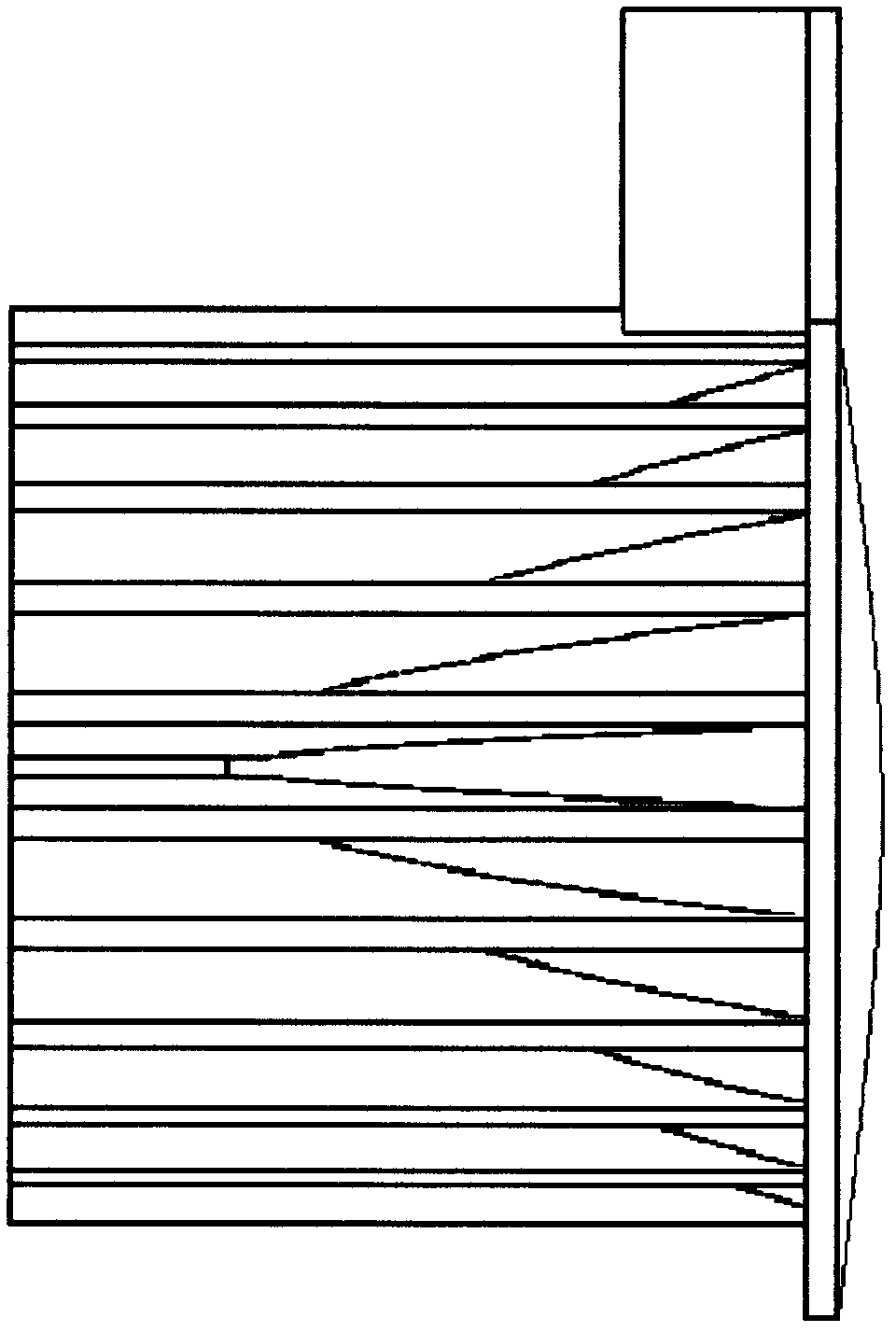

[0026] A LED car headlight light source, cross-sectional view, perspective view and side view respectively refer to figure 1 , figure 2 and image 3 , including a metal shell 10, the metal shell 10 includes an opening 101, an inner side 102, an outer side 103, an inner bottom 104, and an outer bottom 105 opposite to the inner bottom 104, the opening 101, the inner side 102 1. The inner lower surface forms a cavity, the inner surface 102 is an ellipsoid, a base plate 11 is arranged near the focus of the inner surface 102, an LED chip array 12 is arranged on the base plate 11, and an LED chip array 12 is arranged at the opening. A transparent baffle 14, the cavity is filled with a transparent liquid 13.

[0027] In this embodiment, the LED chip array 12 is formed by arranging two or more of red, green, blue, and yellow LED chips according to a predetermined number and a predetermined pitch. For example, the LED chip array can consist of 8 Red chips, 16 green chips, and 8 blu...

Embodiment 2

[0043] A method for manufacturing an LED automobile headlight source, comprising the following steps:

[0044] A base plate is provided, and the LED chip array is fixed on the base plate;

[0045] A metal shell is provided, and the metal shell includes an opening, an inner surface, an outer surface, an inner bottom surface, and an outer bottom surface opposite to the inner bottom surface, and the opening, the inner surface, and the inner bottom surface form a cavity.

[0046] The inner surface is made as an ellipsoid, the bottom plate is arranged near the focal point of the inner surface, and a transparent baffle is arranged at the opening.

[0047] The cavity is filled with a light-transmitting liquid, which is filled into the metal shell by pouring or negative pressure suction, and the light-transmitting liquid may or may not completely fill the metal shell.

[0048] In this embodiment, the fixing of the LED chip array on the base plate includes arranging two or more of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com