Device and method for simultaneously testing water seepage and drainage capacities of asphalt mixture

A technology of asphalt mixture and drainage capacity, which can be used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. It is easy to optimize the design, easy to use and operate, and the design is reasonable and concise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

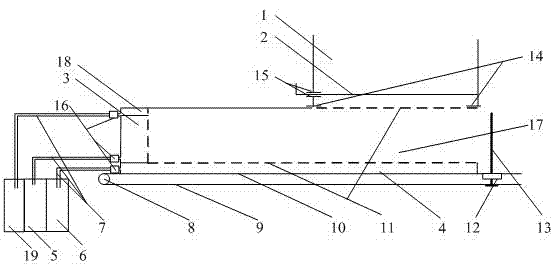

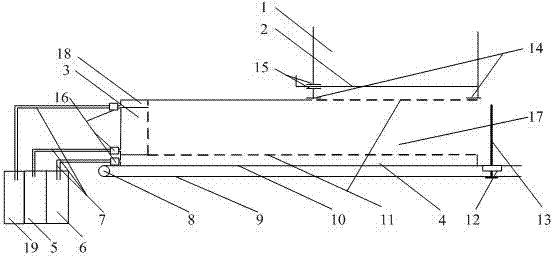

[0030] Example: A comprehensive test method for water seepage and drainage of asphalt mixture, comprising the following steps:

[0031] (1) Forming of asphalt mixture plate specimen

[0032]Considering that in the actual asphalt concrete pavement, each structural layer is usually constructed by layered paving and rolling, and the thickness of each layer is generally 4cm to 8cm. In order to make the asphalt mixture test piece of the drainage and water seepage test reflect the actual situation of each structural layer of the road surface as much as possible, the present invention adopts the plate-type test piece formed by the wheel rolling method in the laboratory as the test object.

[0033] According to the asphalt mixture gradation, asphalt dosage and porosity to be tested, the asphalt mixture is mixed in the laboratory, and the mixed mixture is put into the steel mold used for the rutting test plate, and the asphalt is rolled and formed. The plate test piece of the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com