Anvil cell high pressure device for in situ neutron diffraction

A high-pressure device and an anvil technology, applied in the field of in-situ neutron diffraction experiments, can solve problems such as failure of experiments, inability to test samples with hydraulic loading and pressure, and difficulty in ensuring sample preloading pressure, etc., to achieve good retention and increase flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

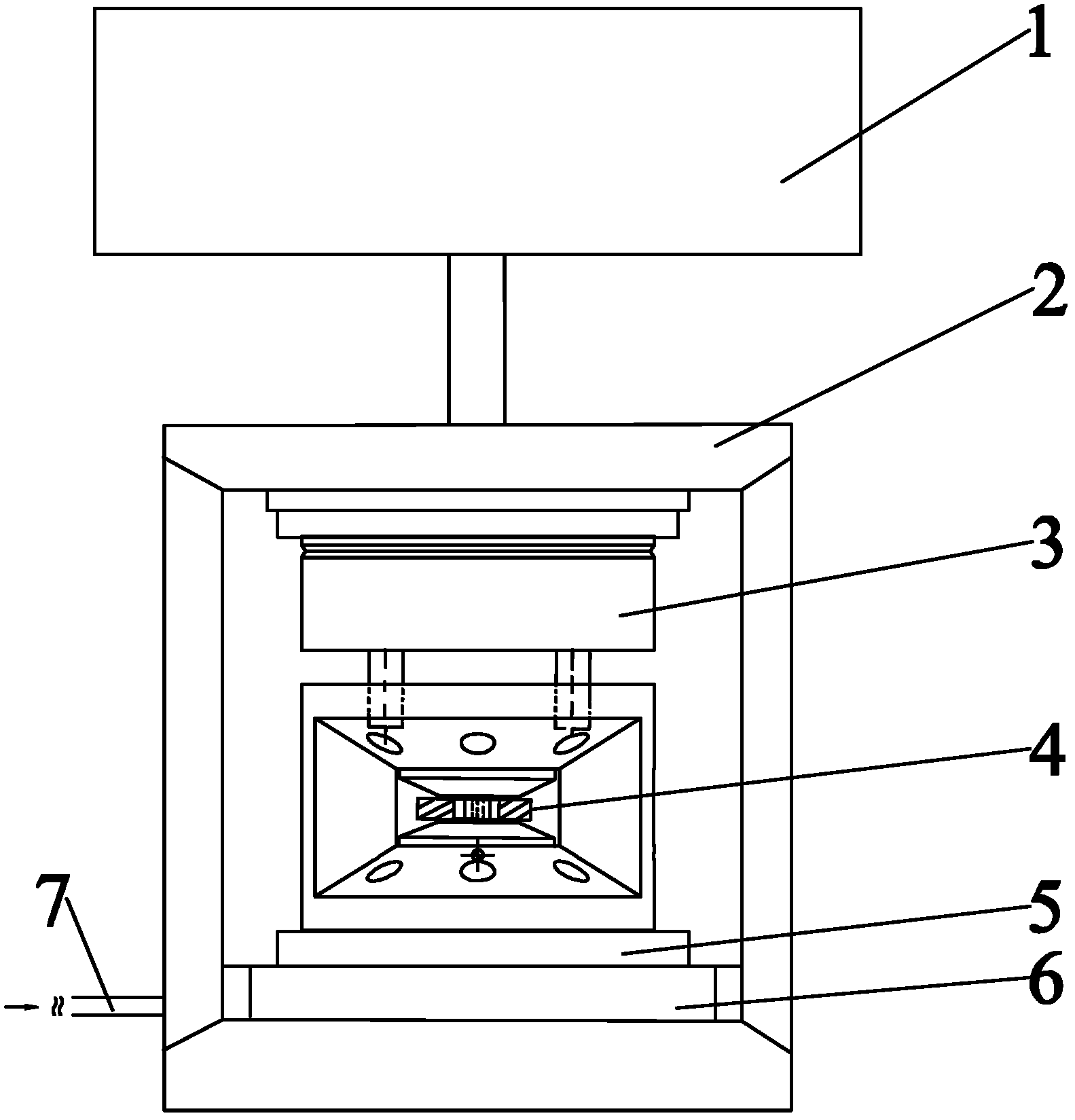

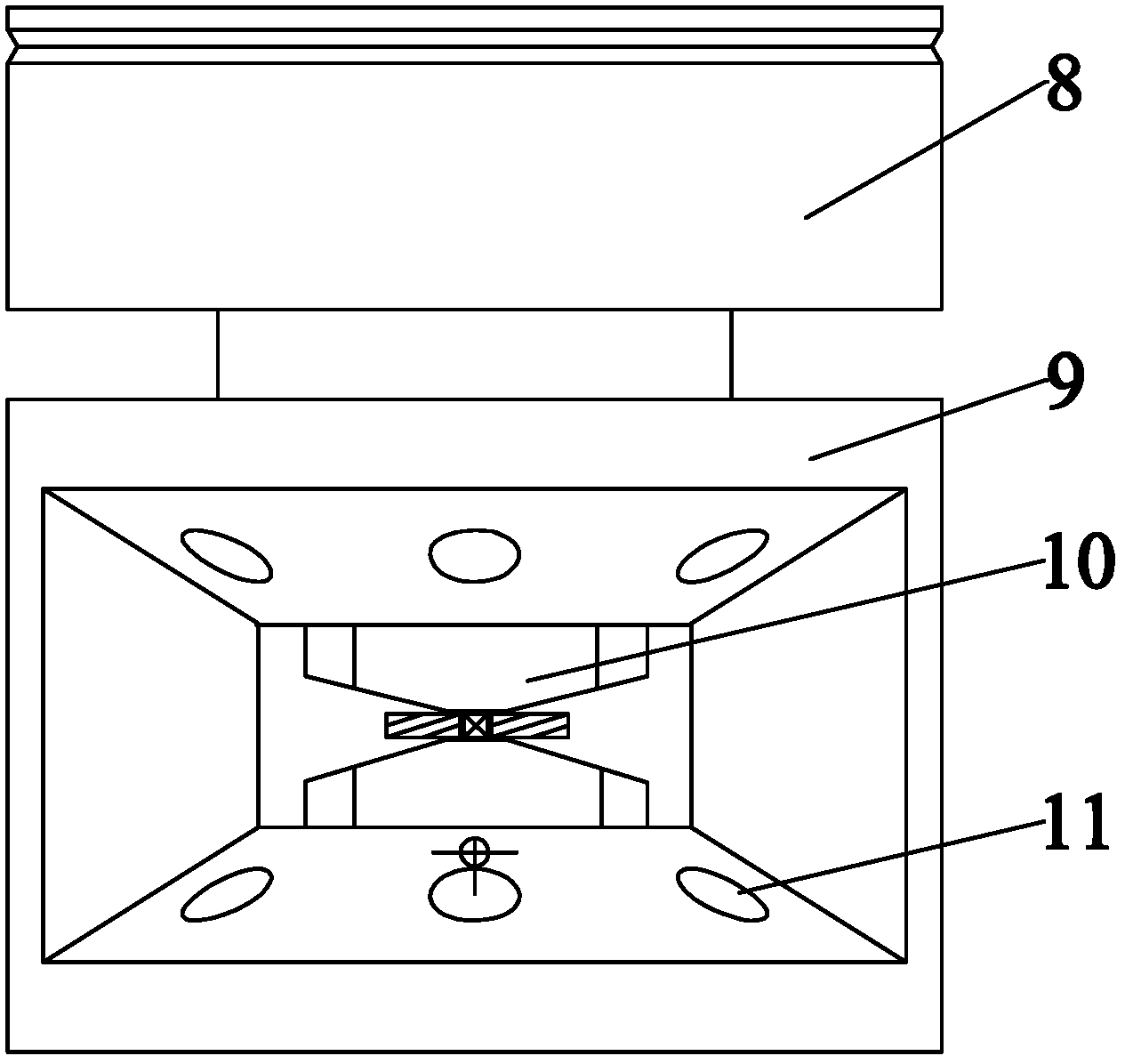

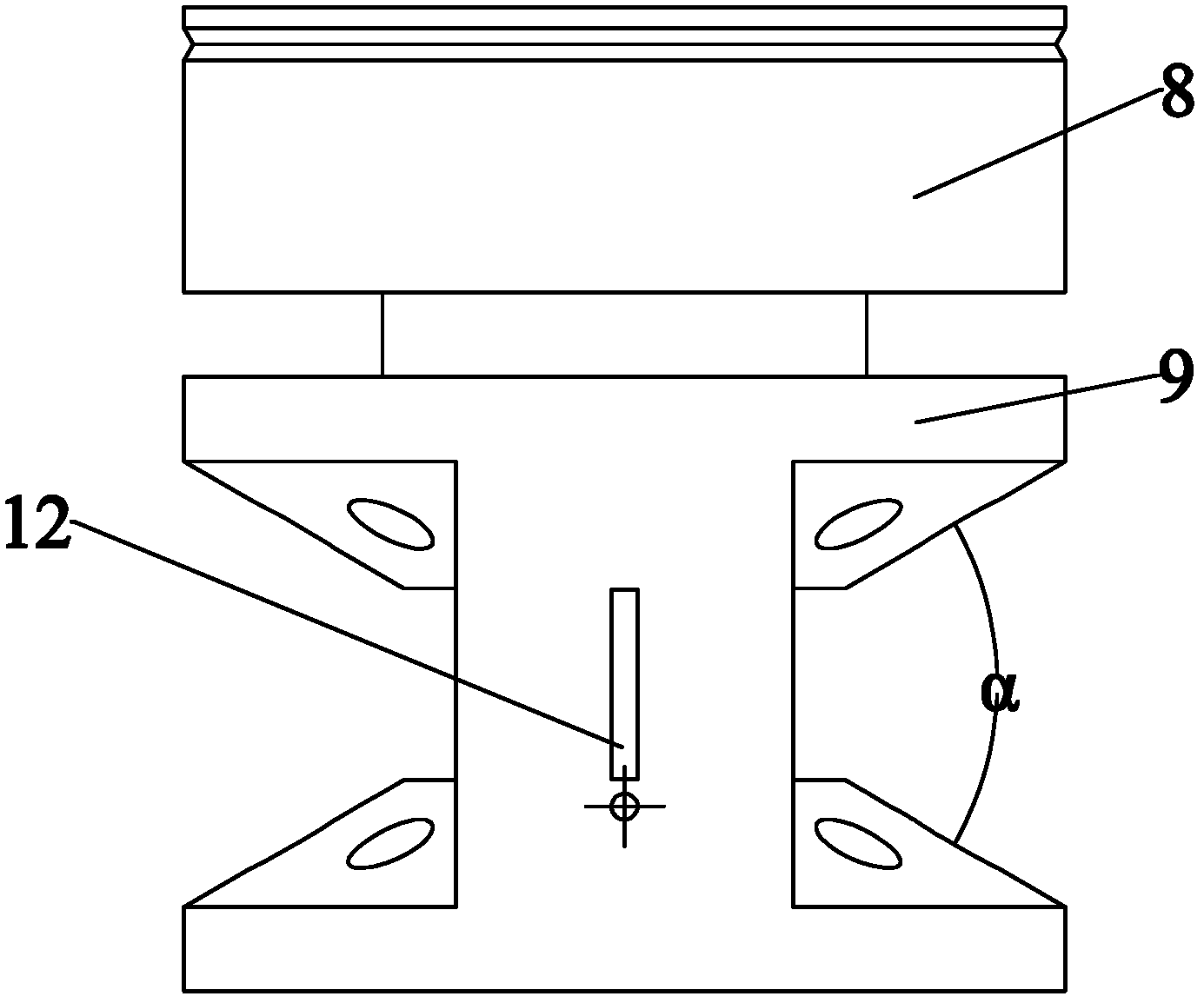

[0031] The in-situ neutron diffraction of the present embodiment uses the anvil high pressure device, and its structure is as attached figure 1 As shown in accompanying drawing 4, it is composed of a body device and a suspension device 1. The body device is provided with a two-stage pressure loading subsystem, consisting of a frame 2, a hydraulic loading subsystem located in the frame, and an internal pressure chamber 3 located in the internal pressure Two anvils 10 opposite to each other in the cavity, a gasket 21 between the two anvils, and a reinforcement ring 20 outside the anvils 10 constitute a mechanical loading subsystem attached to the internal pressure cavity. In the hydraulic secondary loading subsystem, the piston cylinder 6 is fixed on the frame 2, the piston 5 acts on the internal pressure chamber, and the piston cylinder is connected to the hydraulic press far away from the test bench through the high-pressure oil pipe 7. The components of the hydraulic secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com