Nondestructive testing method of paste quality of marine constrained damping rubber plate

A technology of constrained damping and non-destructive testing, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, achieving great economic and social benefits, high reliability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods are provided And specific operation process, but protection scope of the present invention is not limited to following embodiment.

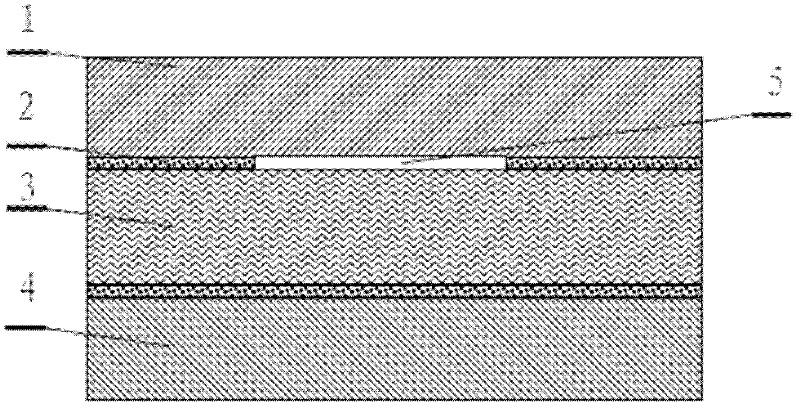

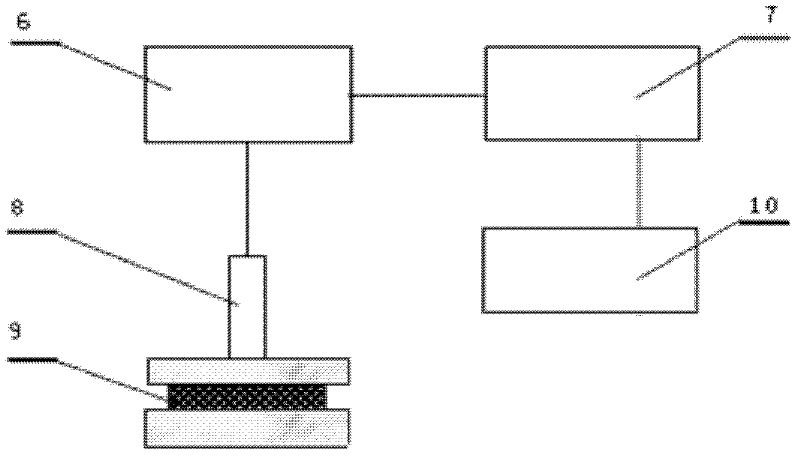

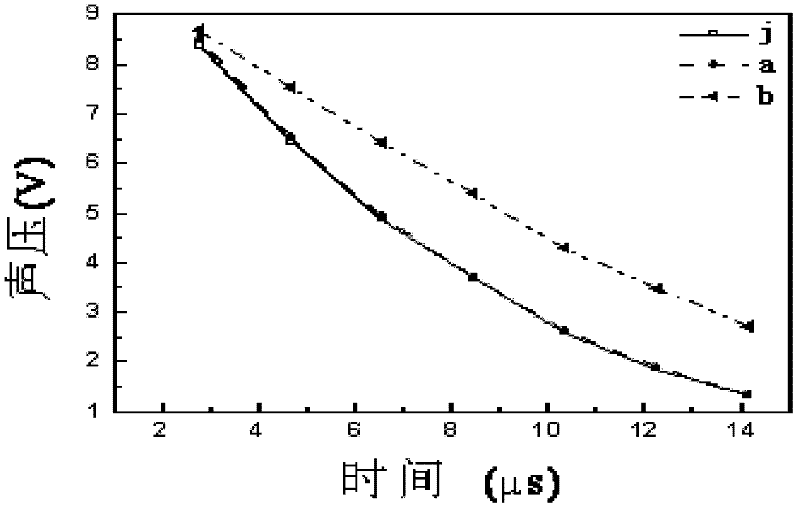

[0019] like figure 1 , 2 As shown, the constrained metal plate 1, the bonding area 2, the damping material 3, the metal plate 4, the debonding area 5, the ultrasonic flaw detector 6, the digital oscilloscope 7, the longitudinal wave straight probe 8, and the constrained damping rubber plate bonded sample 9 , computer 10 . A D-803-Y type constrained damping rubber plate (produced by Tianjin Rubber Research Institute) with a cross-sectional size of 120×100mm is bonded to a 5.5mm thick Q235 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com