Chip package

A chip and assembly technology, applied in the field of semiconductor assembly, can solve problems such as difficulty in controlling the amount of glue, affecting product reliability, and burdening mold costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

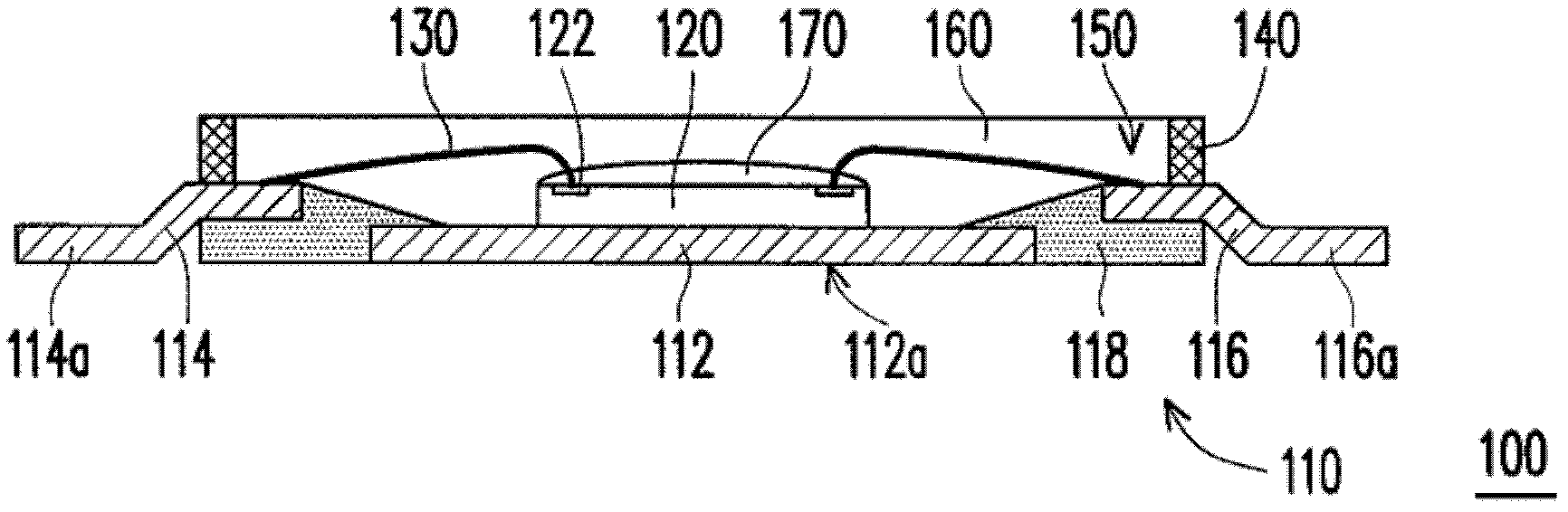

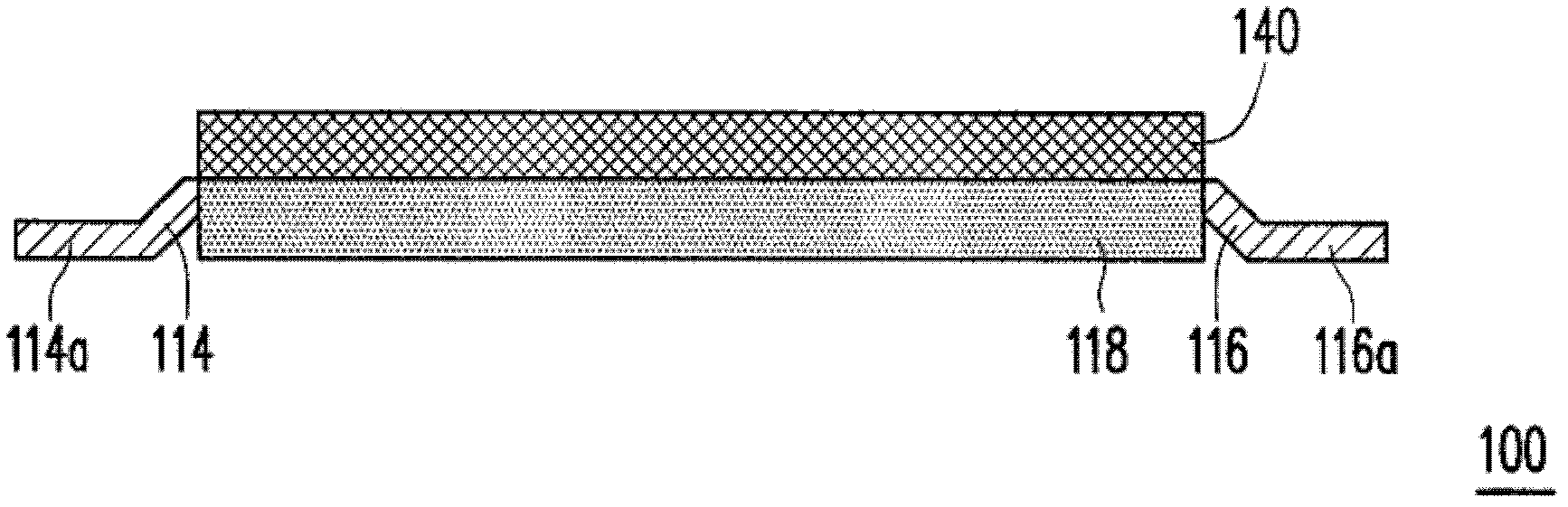

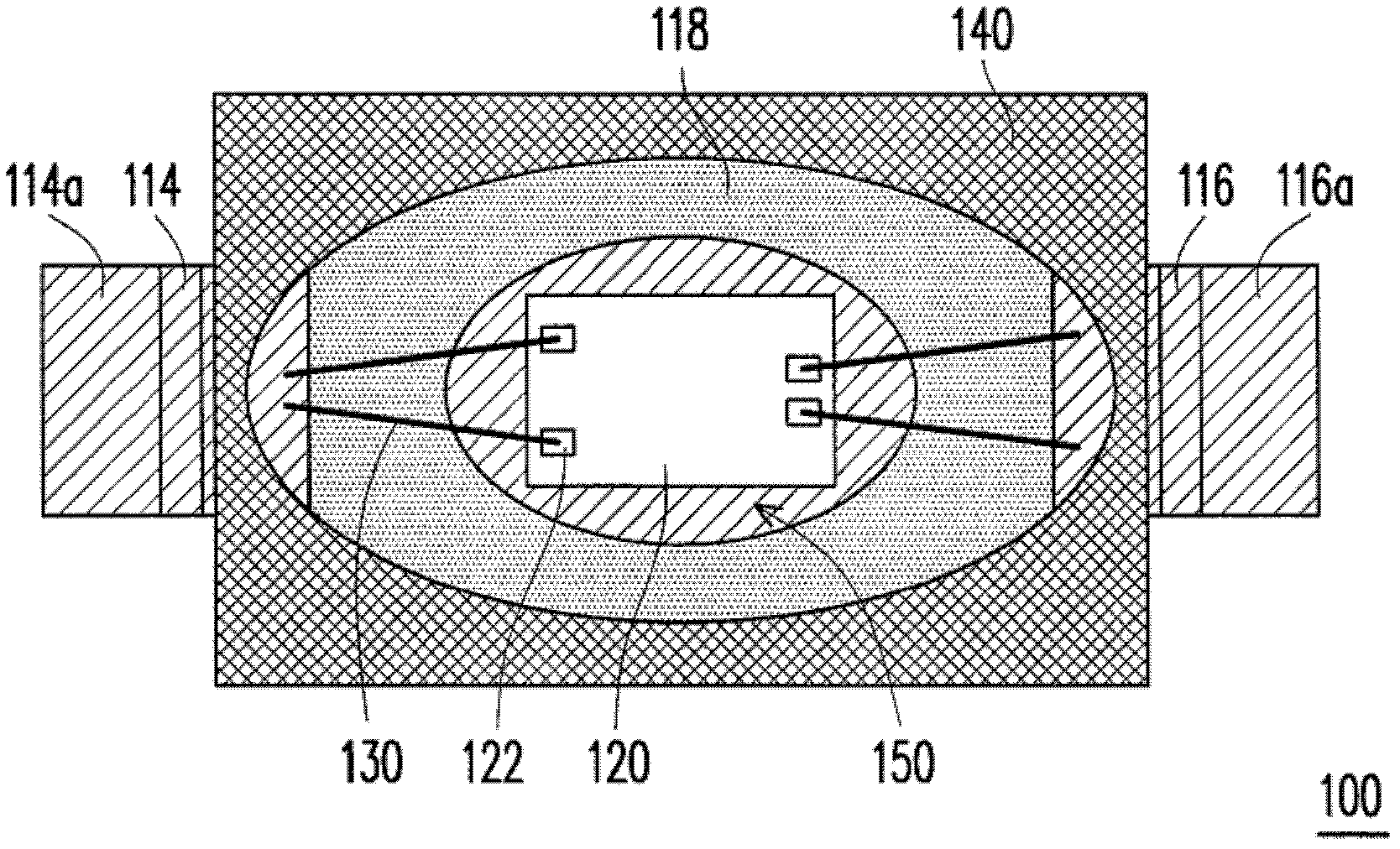

[0066] Please refer to Figure 1A-Figure 1C ,in Figure 1A is a cross-sectional view of a chip structure according to an embodiment of the present invention, Figure 1B and Figure 1C A side view and a top view of the chip assembly, respectively. In order to clearly express the internal structure of the chip structure, Figure 1C Some components are omitted. In this embodiment, the structure of the LED chip 120 is taken as an example to illustrate a technical solution of the present invention, wherein the pre-sealed lead frame 110 is used to carry the LED chip 120, and the pre-sealed lead frame 110 includes a chip holder 112, A plurality of pins (including a positive pin 114 and a negative pin 116 ), and a pre-sealing material 118 . Here, the pre-sealing material 118 is, for example, made of thermoplastic polymer material by injection molding, or thermosetting polymer material by compression molding, especially the thermosetting high polymer material. Molecular materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com