Preparation method of touch screen and touch screen structure

A touch screen and touch sensor technology, applied in the field of touch screens, can solve the problems of reducing the light transmittance of the overall touch screen, application troubles, large absorption wavelengths, etc., and achieve the effect of improving light transmittance and visibility and reducing diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

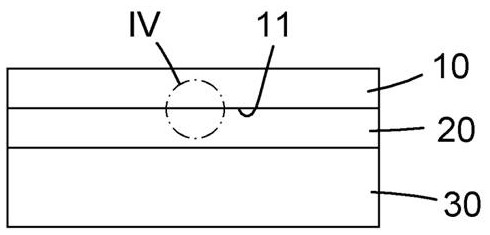

[0028] The preferred embodiments of the present invention are described in the accompanying drawings, wherein, in order to provide a clearer description and easier understanding of the technical features of the present invention, the various parts in the drawings are not drawn according to their relative dimensions, and some dimensions are different from other dimensions. Relative scales have been exaggerated; irrelevant details have not been fully drawn for the sake of brevity.

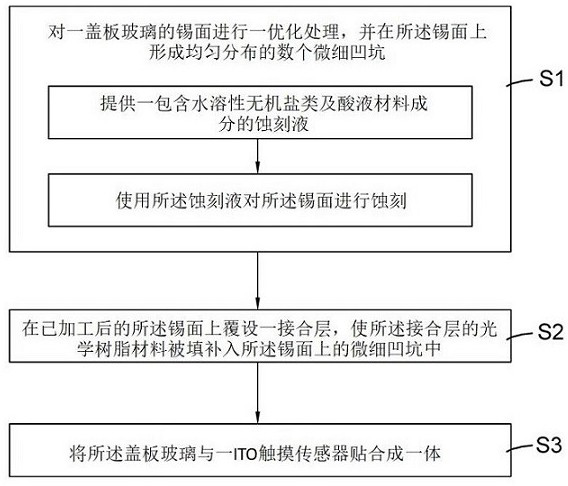

[0029] see figure 1 and figure 2 As shown, the preparation method of the touch screen of the present invention includes steps S1 to S3, and an optional step S4; wherein,

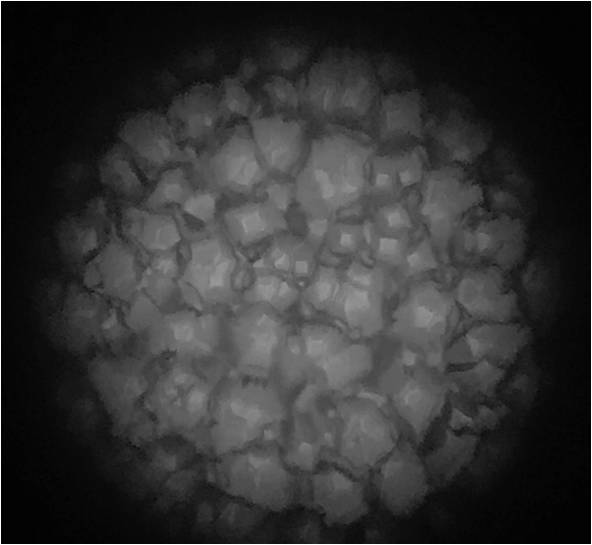

[0030] Step S1, performing an optimization process on the tin surface 11 of the cover glass 10, and forming several fine pits 12 evenly distributed on the tin surface 11:

[0031] A cover glass 10 is provided. The cover glass 10 is a float glass with a length and width of more than 15 inches and a refractive index of about 1.523...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com