Complementary metal oxide semiconductor (CMOS) sensor with octagonal Hall disk structure and manufacturing method for CMOS sensor

A CMOS sensor, regular octagonal technology, applied in the CMOS sensor with regular octagonal Hall plate structure and its production field, can solve the problems of magnetic field measurement error, etc., achieve the reduction of offset, thickness reduction, and increase of average resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

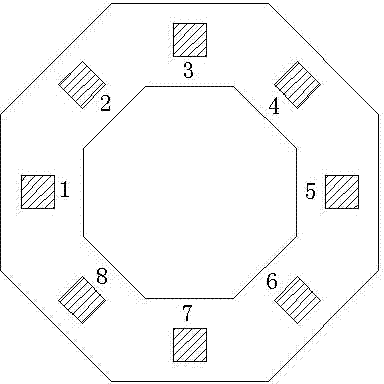

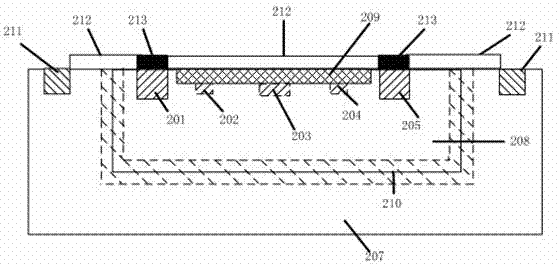

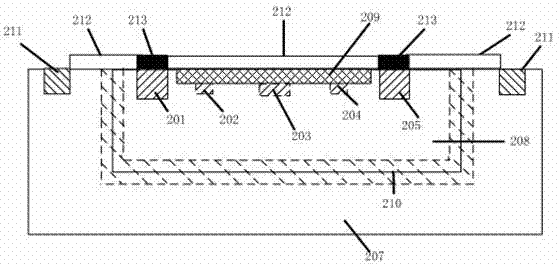

[0018] Such as figure 1 , figure 2 As shown, a CMOS sensor with a regular octagonal Hall disk structure includes a p-type substrate 207, a regular octagonal n-well 208, a p+ doped region 211, an n+ doped region (201, 202, 203, 204, 205 , where 201, 202, 203, 204, and 205 correspond to figure 1 terminal 1, terminal 2, terminal 3, terminal 4 and terminal 5), depletion layer 210, lightly doped p+ doped region 209, oxide layer 212 and aluminum layer 213, the regular octagonal n-well 208 is located On the p-type substrate 207, the p+ doped region 211 is located outside the edge of the regular octagonal n-well 208, and the n+ doped regions (201, 202, 203, 204, 205) are located inside the edge of the regular octagonal n-well 208. The depletion layer 210 is located at the junction of the regular octagonal n-well 208 and the p-type substrate 207, the lightly doped p+ doped region 209 is located above the regular octagonal n-well 208, and the oxide layer 212 is located on the regular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com