High-sensitivity vertical magnetic field sensor with symmetrical structure

A magnetic field sensor and high-sensitivity technology, applied in the direction of the size/direction of the magnetic field, Hall effect devices, and the manufacture/processing of electromagnetic devices, can solve the development requirements that cannot meet the low cost and high integration of magnetic field sensor microsystems, Can not be compatible with silicon-based process, increase production costs and other issues, to achieve the effect of low initial offset, low production cost, and eliminate offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

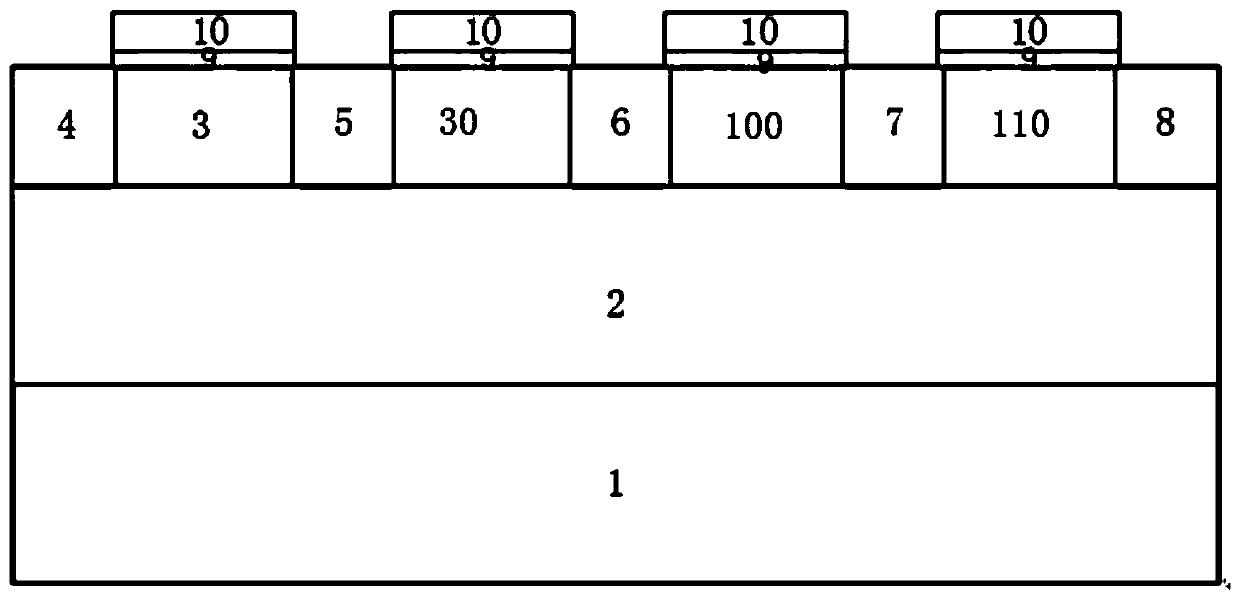

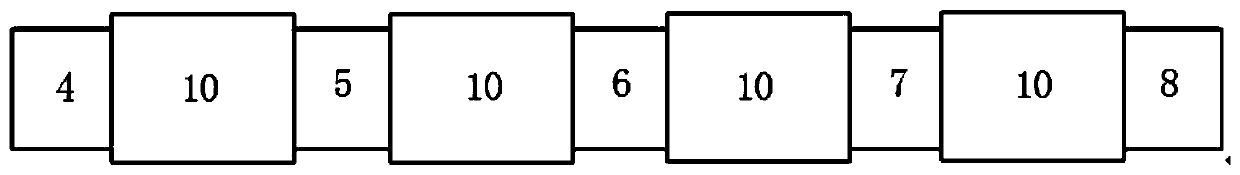

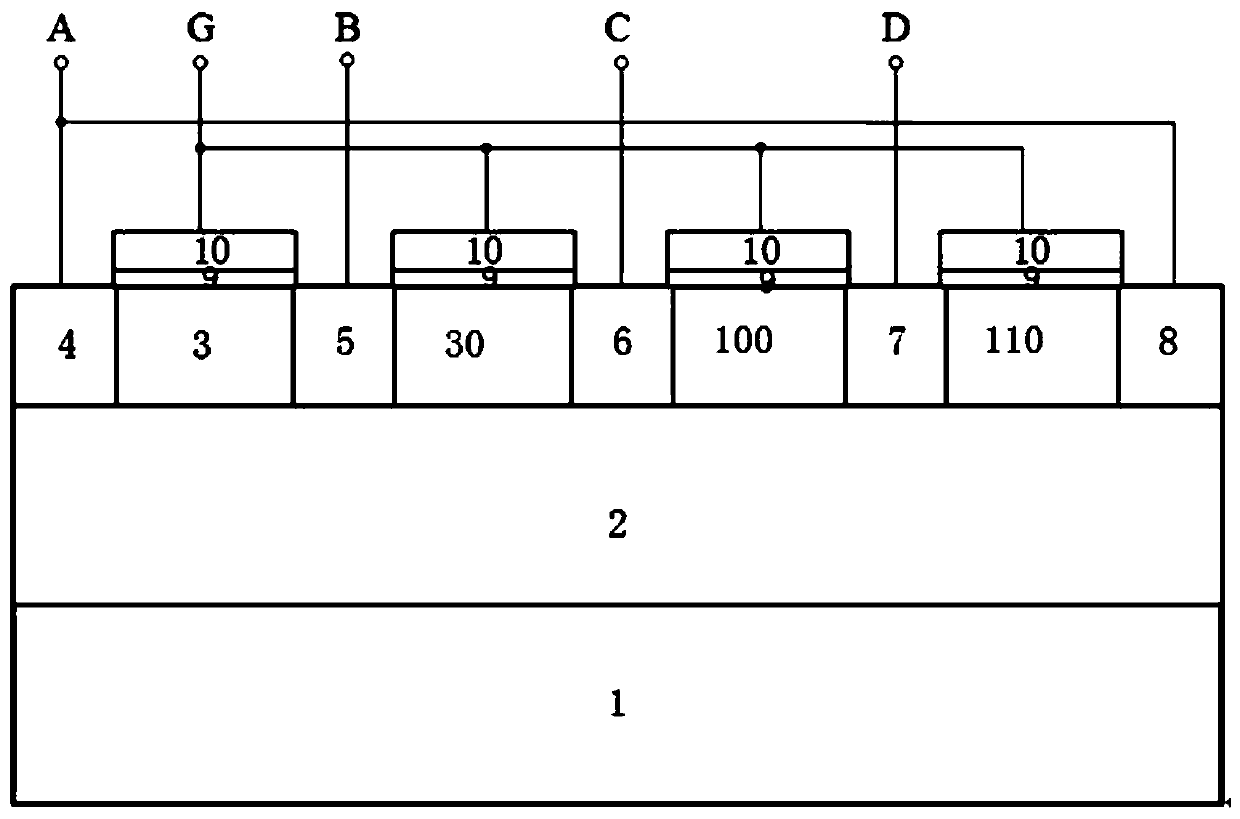

[0024] The present invention discloses a high-sensitivity vertical magnetic field sensor with a symmetrical structure, including a first vertical magnetic field sensor and a second vertical magnetic field sensor arranged vertically symmetrically, such as figure 1 and figure 2 As shown, the first vertical magnetic field sensor and the second vertical magnetic field sensor share the third N+ region 6 .

[0025] The magnetic field sensor includes a silicon substrate 1, an insulator layer 2, a first P-region 3, a second P-region 30, a third P-region 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com