Material with giant magneto-impedance effect and preparation method thereof

A giant magneto-impedance and effect technology, applied in the field of nano-scale materials and preparation, can solve the problems of inconvenient processing and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

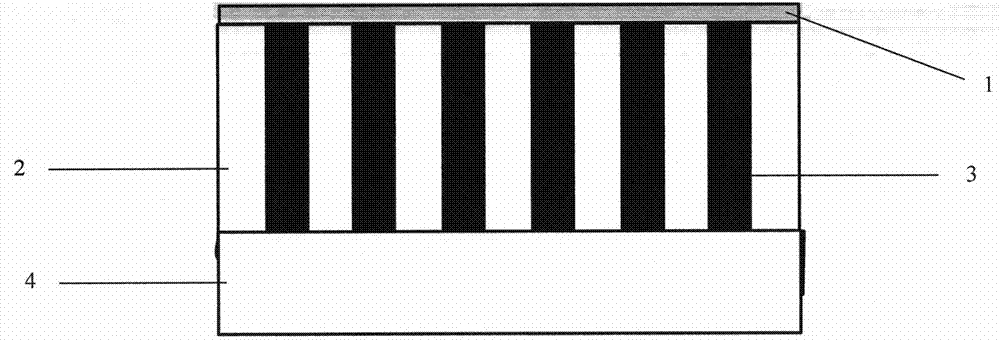

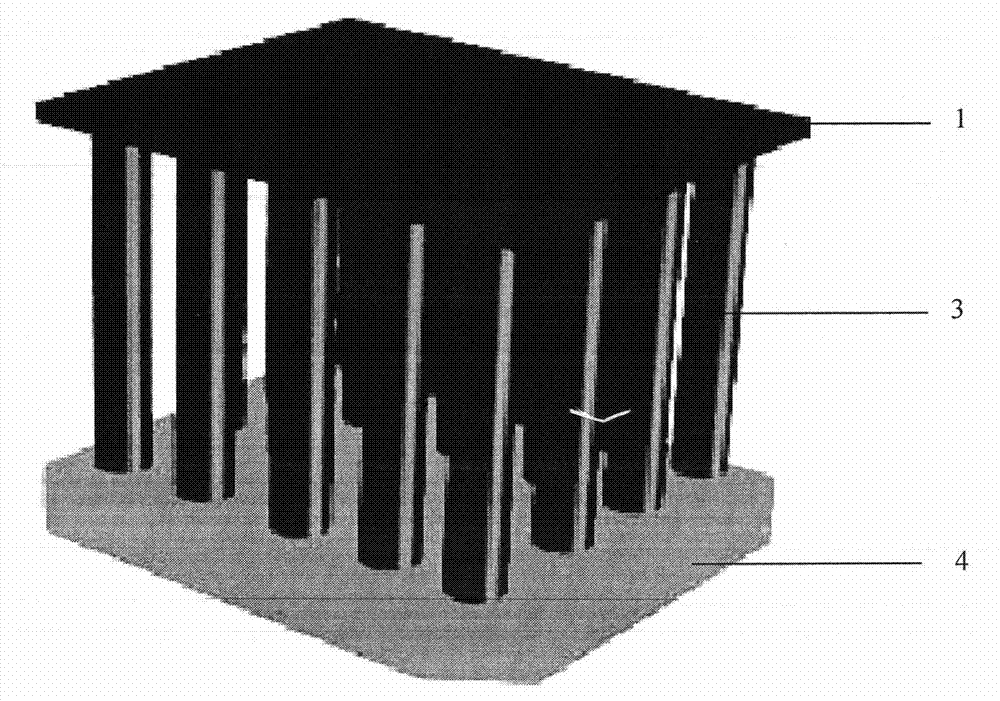

[0016] The polished aluminum sheet is oxidized once in 0.3mol / L oxalic acid solution with a voltage of 40V, and the oxidation time is 1 hour. Then put the aluminum sheet into a mixed solution of phosphoric acid and chromic acid with a mass ratio of 6% and 1.8%, respectively, in a water bath at 60° C. for 20 minutes, take it out, and wash it with distilled water several times. In order to obtain a template with a more complete structure, the second oxidation was carried out under the same conditions as above, and the oxidation time was 4 hours to obtain a nanopore array with a neat and regular structure and a pore diameter of 50 nm. Since the thickness of the template is directly proportional to the oxidation time, the oxidation time can be properly selected. Gradually reduce the voltage to remove the barrier layer and remove it from the solution. The prepared anodized aluminum template was AC electrodeposited in a 1mol / L CoSO4 solution with a pH value of 4.5 for 10 minutes. ...

Embodiment 2

[0018] The polished aluminum sheet is oxidized once in 34g / L phosphoric acid solution with a voltage of 80V, and the oxidation time is 1 hour. Then put the aluminum sheet into a mixed solution of phosphoric acid and chromic acid with a mass ratio of 6% and 1.8%, respectively, in a water bath at 60° C. for 20 minutes, take it out, and wash it with distilled water several times. In order to obtain a template with a more complete structure, the second oxidation was carried out under the same conditions as above, and the oxidation time was 4 hours to obtain a nanopore array with a neat and regular structure and a pore diameter of 100 nm. Since the thickness of the template is directly proportional to the oxidation time, the oxidation time can be properly selected. Gradually reduce the voltage to remove the barrier layer and remove it from the solution. The prepared anodized aluminum template was AC electrodeposited in a 1mol / L CoSO4 solution with a pH value of 4.5 for 10 minutes....

Embodiment 3

[0020]The polished aluminum sheet was oxidized once in 0.6mol / L sulfuric acid solution with a voltage of 20V, and the oxidation time was 1 hour. Then put the aluminum sheet into a mixed solution of phosphoric acid and chromic acid with a mass ratio of 6% and 1.8%, respectively, in a water bath at 60° C. for 20 minutes, take it out, and wash it with distilled water several times. In order to obtain a template with a more complete structure, the second oxidation was performed under the same conditions as above, and the oxidation time was 4 hours to obtain a nanopore array with a neat and regular structure and a pore diameter of 20 nm. Since the thickness of the template is directly proportional to the oxidation time, the oxidation time can be properly selected. Gradually reduce the voltage to remove the barrier layer and remove it from the solution. The prepared anodized aluminum template was AC electrodeposited in a 1mol / L CoSO4 solution with a pH value of 4.5 for 10 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com