Preparation of nanocrystalline material for amorphous external layer

A technology of nanocrystalline materials and amorphous materials, applied in the field of preparation of nanocrystalline materials, can solve problems such as poor mechanical properties, fragility, inferior electrical and magnetic properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

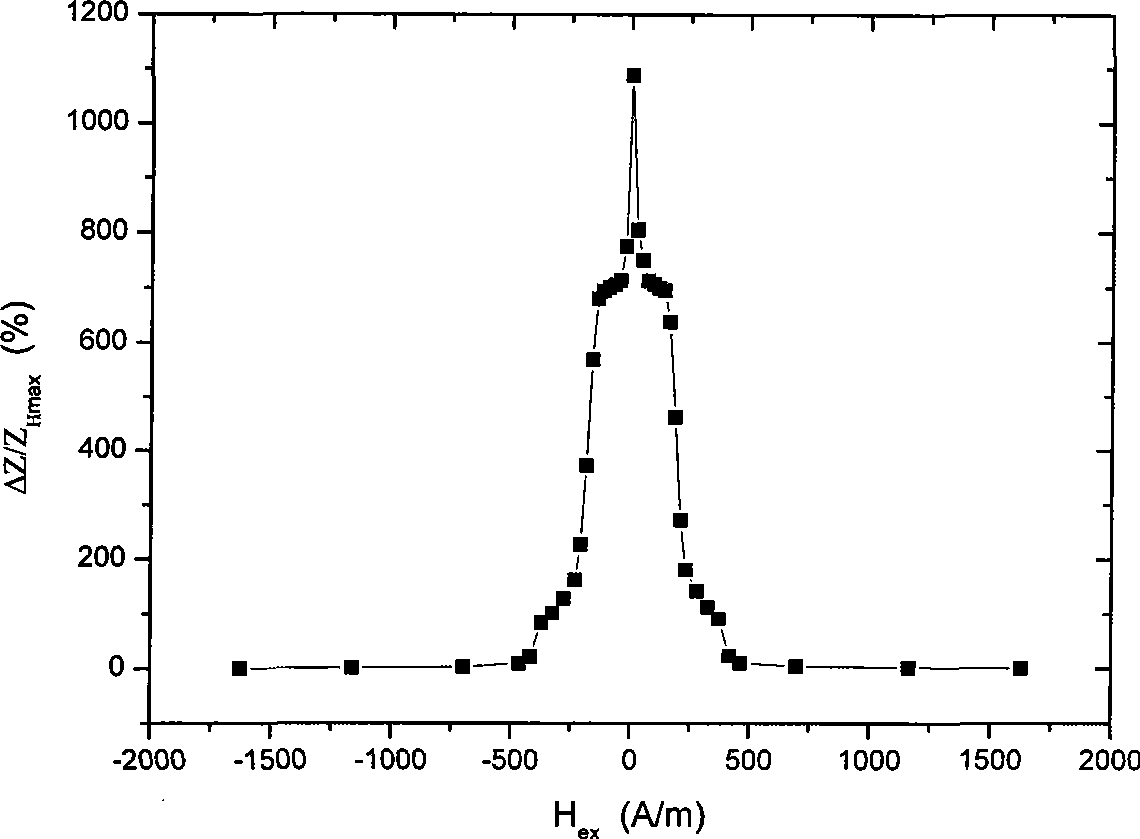

Embodiment 1

[0015] Prepare magnetic sensitive material of the present invention as follows:

[0016] (1) Selection of the master alloy: the composition of the master alloy includes 36% atomic ratio of Fe, 36% atomic ratio of Co, 19.2% atomic ratio of B, 4.8% atomic ratio of Si, and 4% atomic ratio of Nb according to the atomic ratio .

[0017] (2) The amorphous alloy wire of the present invention is prepared by a single-roll rapid quenching method comprising the following sub-steps.

[0018] (a) Put the master alloy composed of the above atomic ratio into a quartz glass tube whose softening temperature is higher than 1400.

[0019] (b) Under the protection of argon, heat the master alloy by high-frequency induction until it melts, and continue to heat until superheated.

[0020] (c) Ventilate and pressurize the molten alloy to spray from the nozzle at the bottom of the quartz glass tube to the smooth surface of the high-speed rotating cooling roller, so that the molten alloy liquid is c...

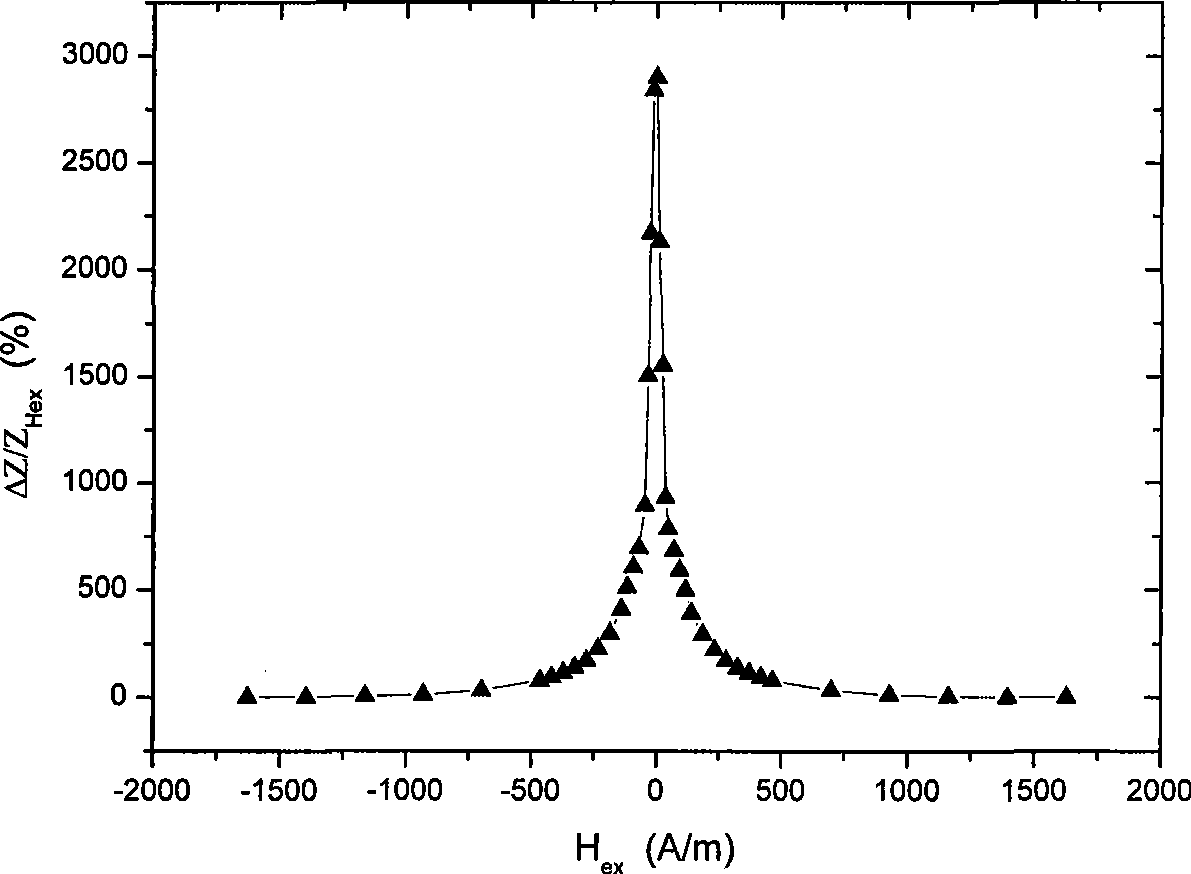

Embodiment 2

[0026] Prepare highly sensitive magnetic sensitive material of the present invention as follows:

[0027] (1) Selection of the master alloy: the composition of the master alloy includes 56% atomic ratio of Fe, 16% atomic ratio of Co, 19.2% atomic ratio of B, 4.8% atomic ratio of Si, and 4% atomic ratio of Nb according to the atomic ratio .

[0028] (2) The amorphous alloy wire of the present invention is prepared by a single-roll rapid quenching method comprising the following sub-steps.

[0029] (a) Put the master alloy composed of the above atomic ratio into a quartz glass tube whose softening temperature is higher than 1400°C.

[0030] (b) Under the protection of argon, heat the master alloy by high-frequency induction until it melts, and continue to heat until superheated.

[0031] (c) Ventilate and pressurize the molten alloy to spray from the nozzle at the bottom of the quartz glass tube to the cooling roller rotating at high speed to cool the molten alloy liquid into ...

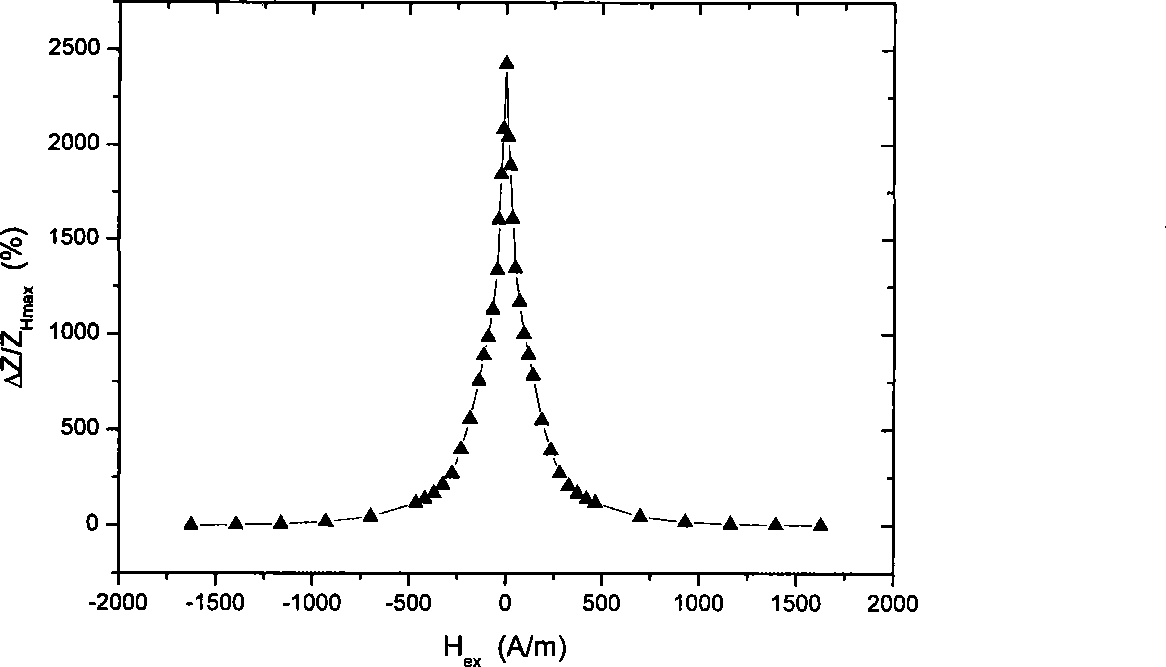

Embodiment 3

[0036] Prepare highly sensitive magnetic sensitive material of the present invention as follows:

[0037] (1) Selection of the master alloy: the composition of the master alloy includes 73.5% atomic ratio of Fe, 1% atomic ratio of Cu, 9% atomic ratio of B, 13.5% atomic ratio of Si, and 3% atomic ratio of Nb according to the atomic ratio .

[0038] (2) The amorphous alloy wire of the present invention is prepared by a single-roll rapid quenching method comprising the following sub-steps.

[0039] (a) Put the master alloy composed of the above atomic ratio into a quartz glass tube whose softening temperature is higher than 1400°C.

[0040] (b) Under the protection of argon, heat the master alloy by high-frequency induction until it melts, and continue to heat until superheated.

[0041] (c) Ventilate and pressurize the molten alloy to spray from the nozzle at the bottom of the quartz glass tube into the water rotating at high speed, so that the molten alloy liquid is cooled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com