Method for preparing internal support polyvinylidene fluoride hollow fiber membrane

A technology of polyvinylidene fluoride and fiber membrane, which is applied in chemical instruments and methods, membrane technology, and semipermeable membrane separation, etc. The resin process is not easy to operate and other problems, to reduce the possibility of broken wires and fouling, the performance and coating process requirements are not high, and the effect of avoiding the influence of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

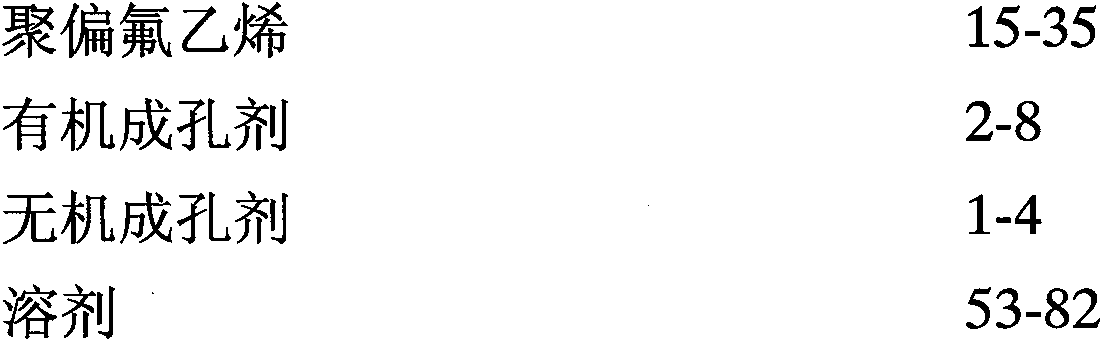

Method used

Image

Examples

Embodiment 1

[0031] (1) 17.5g of polyvinylidene fluoride resin with a weight average molecular weight of 600,000, 1g of polyvinylpyrrolidone (K90), 0.5g of anhydrous lithium chloride, and 31g of dimethylformamide are uniformly mixed at 90°C, Stirring, dissolving, filtering and defoaming to obtain a polyvinylidene fluoride casting solution with a mass concentration of 35%;

[0032] (2) The polyester hollow braided rope with an inner diameter of 0.5mm and an outer diameter of 1.2mm is soaked in a 10% sodium hydroxide aqueous solution for 0.5h at a mass concentration of 80°C, taken out, washed and dried, and the braided rope The rope is processed at a speed of 10m / min under normal pressure plasma with a nozzle diameter of 2.5cm, a nozzle height of 2mm, a frequency of 8KHz, a voltage of 16kV, a discharge gas of argon, and a gas flow rate of 10L / min;

[0033] (3) The hollow braided rope processed in step (2) and the mass concentration of 35% polyvinylidene fluoride casting solution prepared in ...

Embodiment 2

[0035] (1) 7.5g of polyvinylidene fluoride resin with a weight average molecular weight of 400,000, 4g of polyvinylpyrrolidone (K12), 1.5g of ammonium chloride, and 37g of dimethylacetamide are uniformly mixed and stirred at 30°C, Dissolving, filtering and defoaming to obtain a polyvinylidene fluoride casting solution with a mass concentration of 15%;

[0036] (2) The polyethylene hollow braided rope with an inner diameter of 2.2mm and an outer diameter of 3.2mm is soaked in an aqueous solution of 10% sodium hydroxide for 1 hour at a temperature of 30°C, and then washed and dried in water. At a speed of 4m / min, the diameter of the nozzle is 2.5cm, the height of the nozzle is 2mm, the frequency is 16KHz, the voltage is 20kV, the discharge gas is oxygen, and the gas flow rate is 1L / min.

[0037](3) The hollow braided rope processed in step (2) and the mass concentration of 15% polyvinylidene fluoride casting solution prepared in step (1) pass through the spinneret (the inner hol...

Embodiment 3

[0039] (1) 9g polyvinylidene fluoride resin with a weight average molecular weight of 700,000, 1.5g polyethylene glycol (molecular weight 200), 1g polyvinylpyrrolidone (K17), 0.5g ammonium chloride, 0.5g calcium chloride, 37.5 gN-Methylpyrrolidone was uniformly mixed, stirred, and dissolved at 50°C, and after filtering and defoaming, a polyvinylidene fluoride casting solution with a mass concentration of 18% was obtained;

[0040] (2) Soak a polyamide hollow braided rope with an inner diameter of 1.8mm and an outer diameter of 3.0mm at 60°C for 0.4h with a mass concentration of 10% sodium hydroxide aqueous solution, take it out and wash it in the air, and the braided rope The rope is processed at a speed of 2m / min in an atmospheric pressure plasma with a nozzle diameter of 2.5cm, a nozzle height of 2mm, a frequency of 20KHz, a voltage of 3kV, a discharge gas of helium, and a gas flow rate of 20L / min;

[0041] (3) The hollow braided rope processed in step (2) and the mass conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com