Method for automatically changing slag line of tundish submersed nozzle for ultra-thick plate blank casting machine

An ultra-thick slab and immersion technology, applied in the field of slab continuous casting, can solve the problems affecting the melting and consumption of mold powder, affecting the quality of cast slab, and precision deviation, so as to reduce the number of replacement nozzles and reduce judgment Waste rate and service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

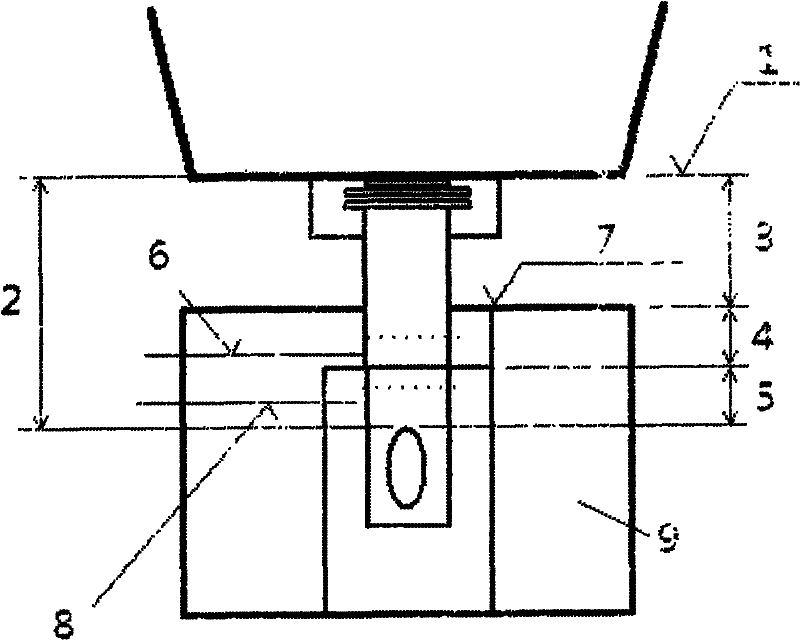

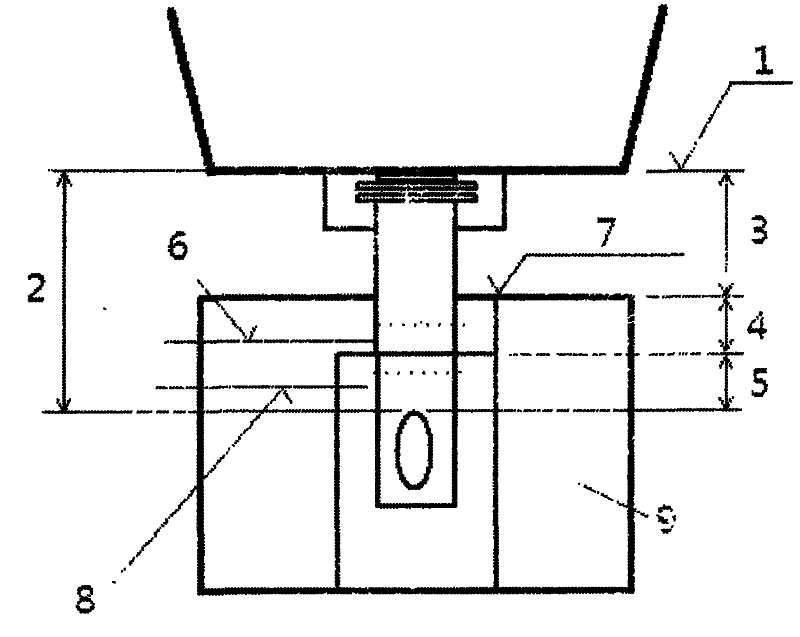

[0014] According to the position limit of the lifting hydraulic cylinder on both sides of the tundish, and the various sizes of the submerged nozzle of the tundish, and then using the calculation principle of the submerged nozzle depth, the automatic slag change line technology of the submerged nozzle of the tundish is realized. The specific calculation principle and operation are as follows:

[0015] The distance from the bottom of the tundish car to the top of the submerged nozzle is 870mm (serial number 2), the distance from the bottom of the tundish car to the top of the copper plate of the mold is 595mm (serial number 3) when the tundish car is full and low, and the actual mold liquid level is 80mm (serial number 4), according to The actual submerged nozzle immersion depth of the formula = 2-(1+3+4), when the actual elevation of the tundish car is 25mm (serial number 1), the actual immersion depth of the submerged nozzle is 170mm; the actual elevation of the tundish car is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com