Manufacturing method of worm gear pair

A manufacturing method and technology for worms, which are applied to worms, worm gears, components with teeth, etc., can solve problems such as difficulties in the design and manufacture of toroidal worms, and achieve improved efficiency, advanced parameters, and avoidance of undercuts and tooth tips. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

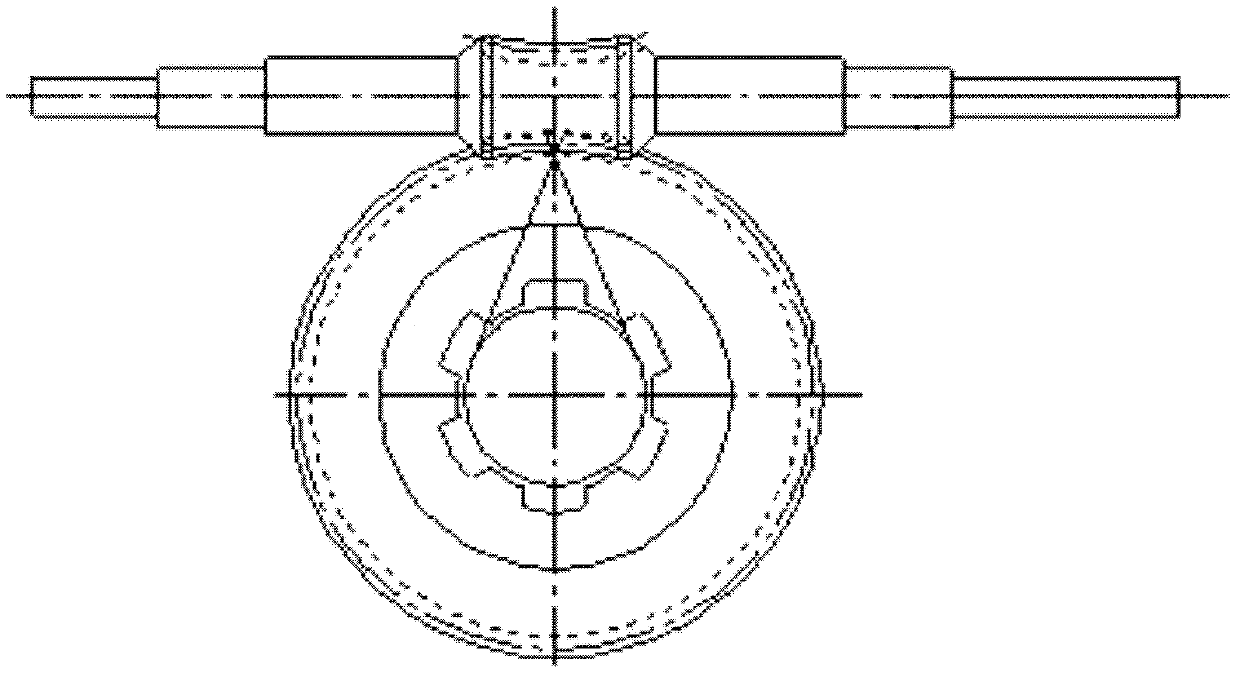

[0045] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts use the same reference numerals.

[0046] First, some technical terms in this article are explained as follows:

[0047] Worm inlet: The worm is the active part, and the tooth surface first contacts the end of the worm gear.

[0048] Worm outlet: The worm is the active part, and the end of the tooth surface that is finally out of contact with the tooth surface of the worm gear.

[0049] Displacement of center distance: The center distance of the worm and the worm gear is different, but it does not change during processing.

[0050] Transmission ratio displacement: The transmission ratio of the worm and the worm gear is different, but it does not change during processing.

[0051] Variable center distance: When proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com