Preparation method oriented to fine-grain diamond abrasive material single-layer soldering tool

A diamond, fine-grained technology, applied in the field of abrasive tool manufacturing, which can solve problems such as processing accuracy limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

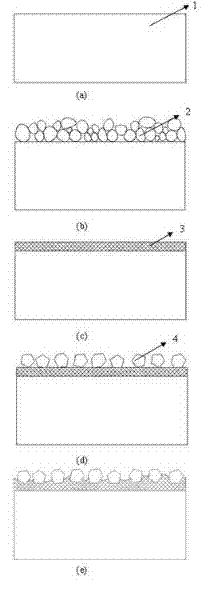

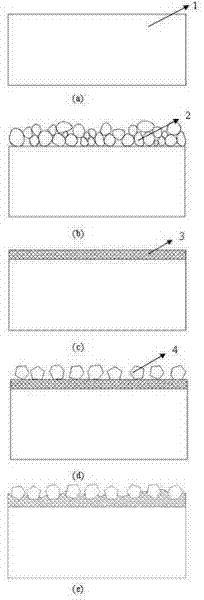

[0027] A method for preparing a single-layer brazing tool for fine-grained diamond abrasives, comprising the following steps:

[0028] The first step: if figure 1 (a), figure 1 As shown in (b), the working surface of the substrate 1 is polished, and a layer of alloy solder powder layer 2 is evenly spread on the working surface;

[0029] The second step: under the condition of high temperature and vacuum, the substrate 1 with the alloy solder powder layer 2 obtained in the first step is sent into a vacuum furnace for the first brazing;

[0030] Step 3: If figure 1 As shown in (c), the surface after brazing in the second step above is polished to form a solder layer 3;

[0031] Step 4: If figure 1 As shown in (d), a layer of fine-grained diamond abrasive 4 is spread on the surface of the solder layer 3;

[0032] The fifth step: send it into the vacuum furnace, and carry out the second brazing under the condition of high temperature and vacuum;

[0033] Step 6: If figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com