Super-large variable vibrating feeder

A vibrating feeder, variable technology, applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of high power consumption, slow feeding speed, heavy maintenance workload, etc., and achieve convenient adjustment of feeding volume , flexible angle adjustment and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

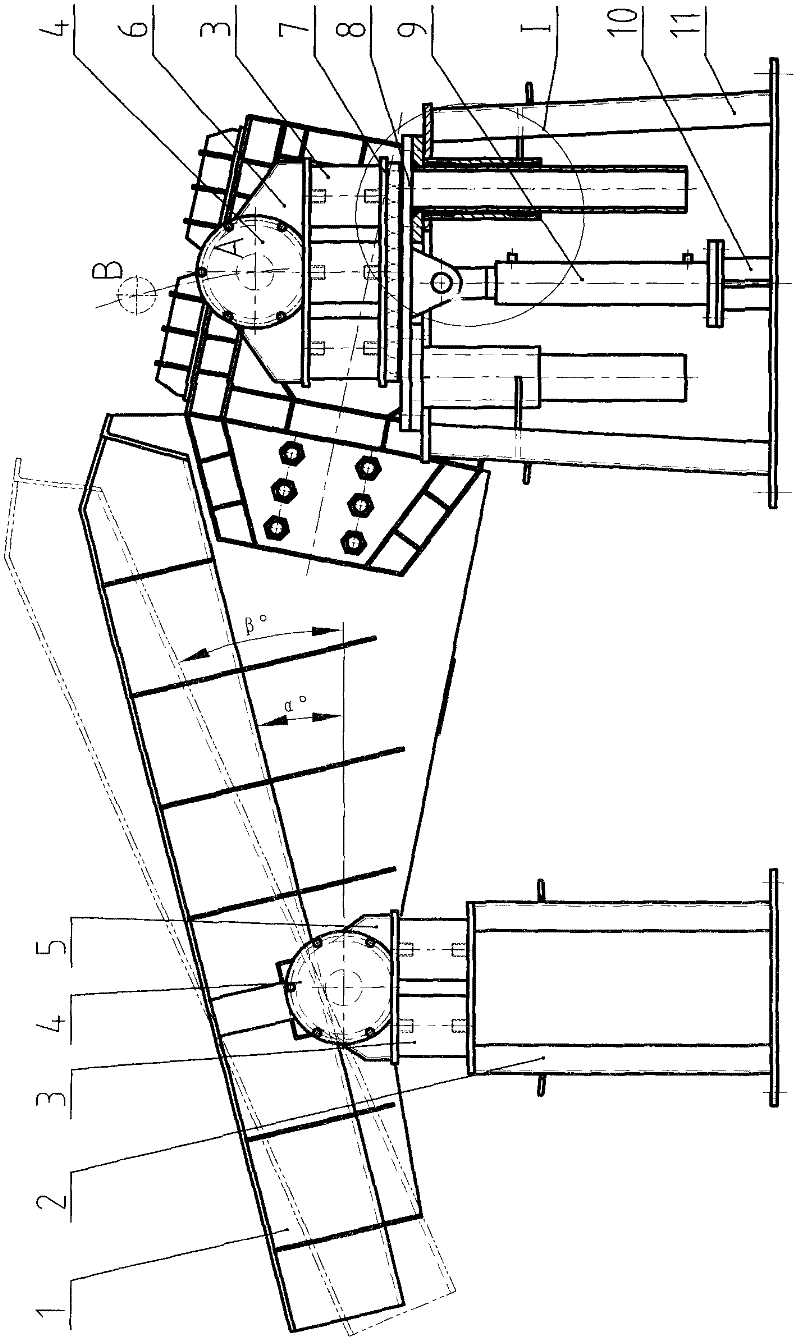

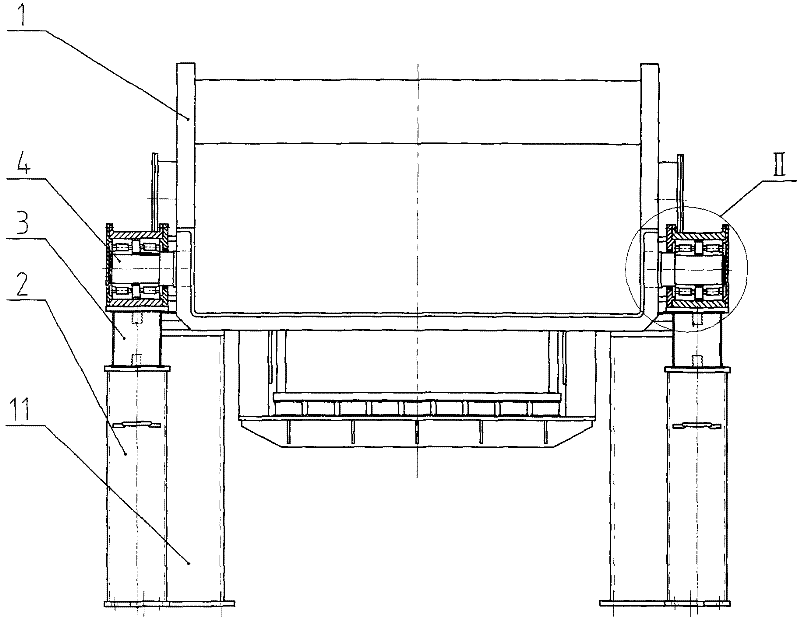

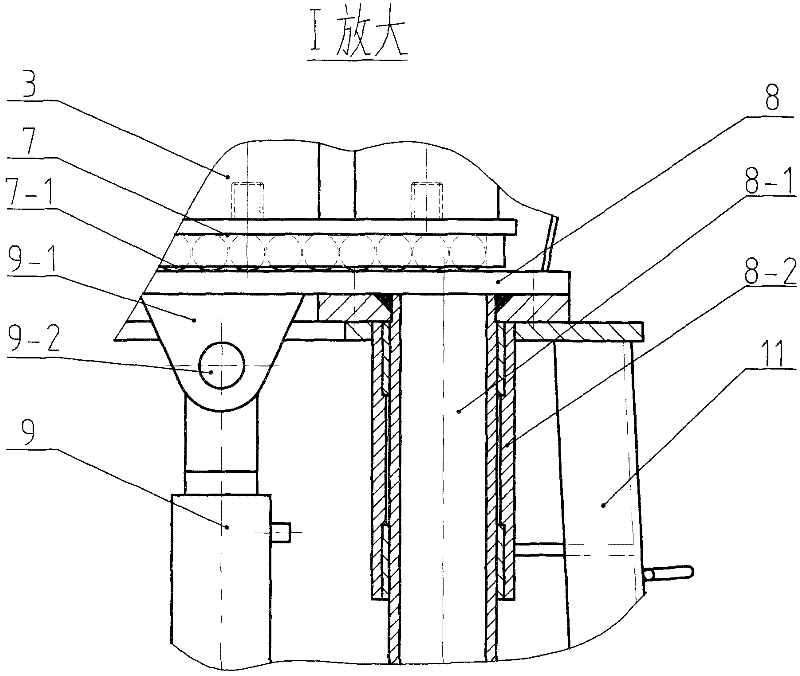

[0017] control Figure 1~4 , the super large variable vibrating feeder of the present invention consists of a vibrating feeder 1, a front support 2, a damping spring 3, a bearing body 4, a front pressing plate 5, a rear pressing plate 6, a displacement device 7, a lifting plate 8, an oil cylinder 9, Oil cylinder support 10 and rear support 11 constitute.

[0018] Its specific structural features are: the two sides of the front end of the vibrating feeder 1 are respectively equipped with the front support 2, the damping spring 3, the front pressure plate 5 and the bearing body 4, and the two sides of the rear end of the vibrating feeder 1 are respectively equipped with Bearing body 4 and rear pressure plate 6, the following of rear pressure plate 6 is connected with displacement device 7 by damping spring 3, and roller 7-1 is housed in displacement device 7, and the upper plane support roller 7-1 of lifting plate 8, its The lug 9-1 is welded below, and is connected with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com