Polypropylene-based microcellular foaming wood-plastic composite material and production method thereof

A production method and microcellular foaming technology, which is applied in the field of wood-plastic composite materials, can solve the problems of large wear of extruder barrel and screw, limited application range of materials, and short service life of extruder, so as to prolong the service life , reduce material density, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

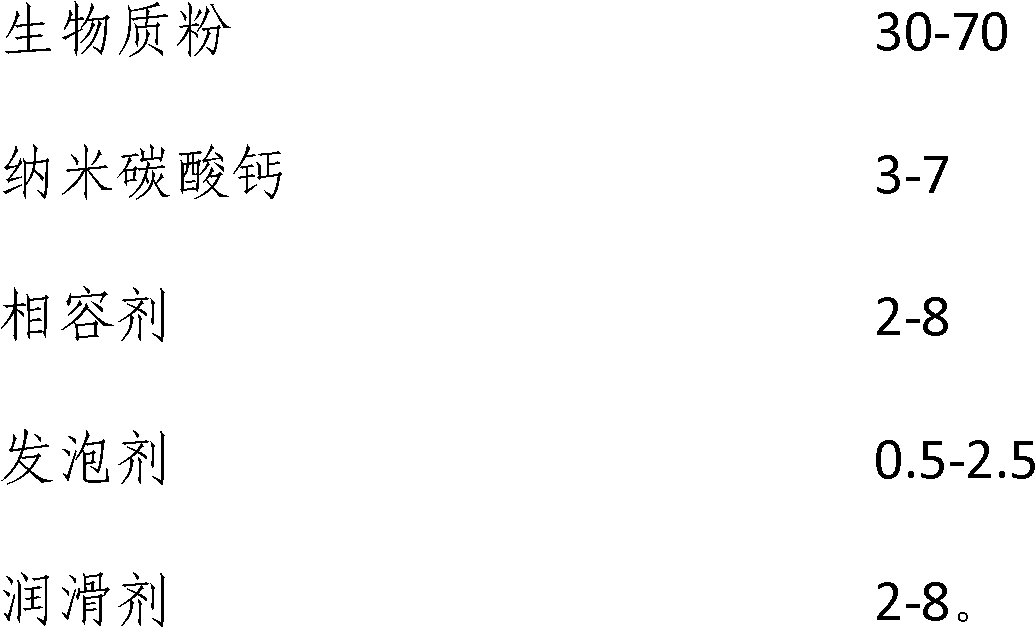

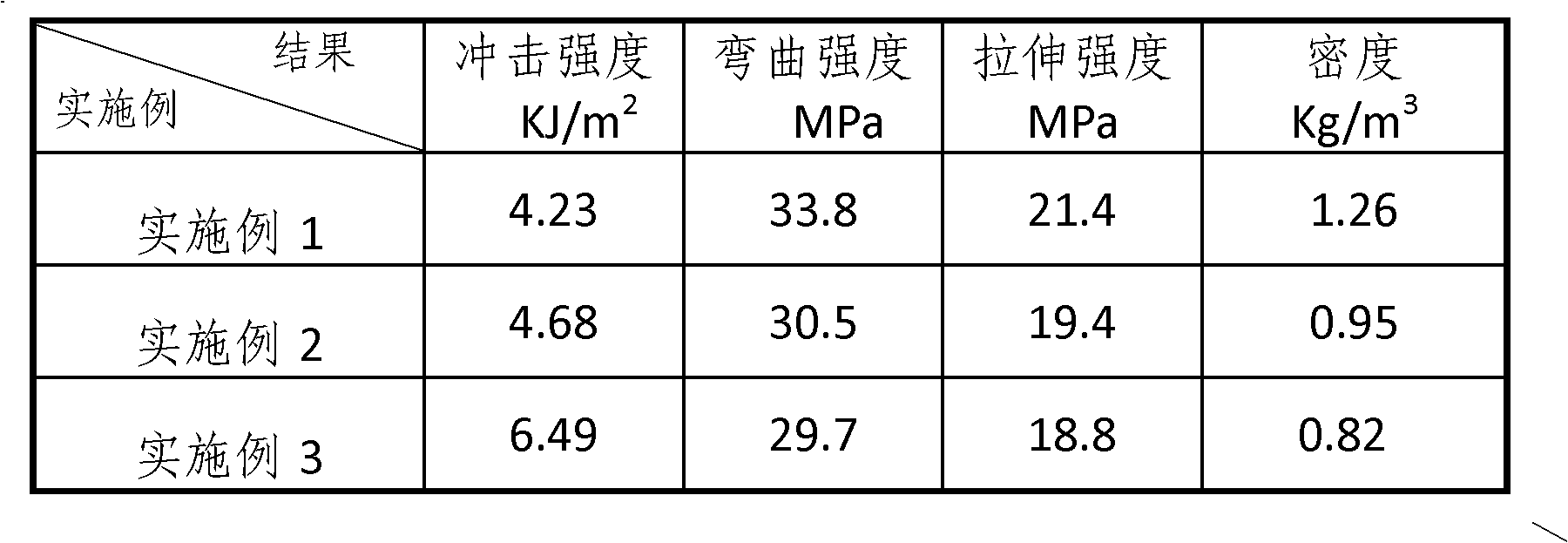

[0024] Embodiment 1-3: formula (unit: weight part)

[0025]

Example 1

Example 2

Example 3

70

70

70

Low-density polyethylene

30

30

30

5

5

5

[0026] biomass powder

50

50

50

Compatibilizer

6

6

6

2.5

2.5

2.5

[0027] Preparation method: prepare according to the formula of Example 1-3.

[0028] 1) Add biomass powder and nano-calcium carbonate into a high-mixer and mix in a weight ratio of 10:1, the mixing temperature is 105°C-110°C, and the mixing time is 15-20 minutes;

[0029] 2) Add 70 parts of polypropylene, 30 parts of low-density polyethylene, 50 parts of treated biomass powder, 6 parts of compatibilizer, and 0.5, 1.5, and 2.5 parts of lubricant into a high-speed mixer in proportion by weight. The temperature is 105°C-110°C, and the mixing time is 15-20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com