Method and device for preparing fuel oil by utilizing solar energy to crack waste plastics

A technology for waste plastics and fuel oil, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of environmental pollution, large energy consumption, destruction, etc., and achieve the effect of reducing production costs, reducing harm, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

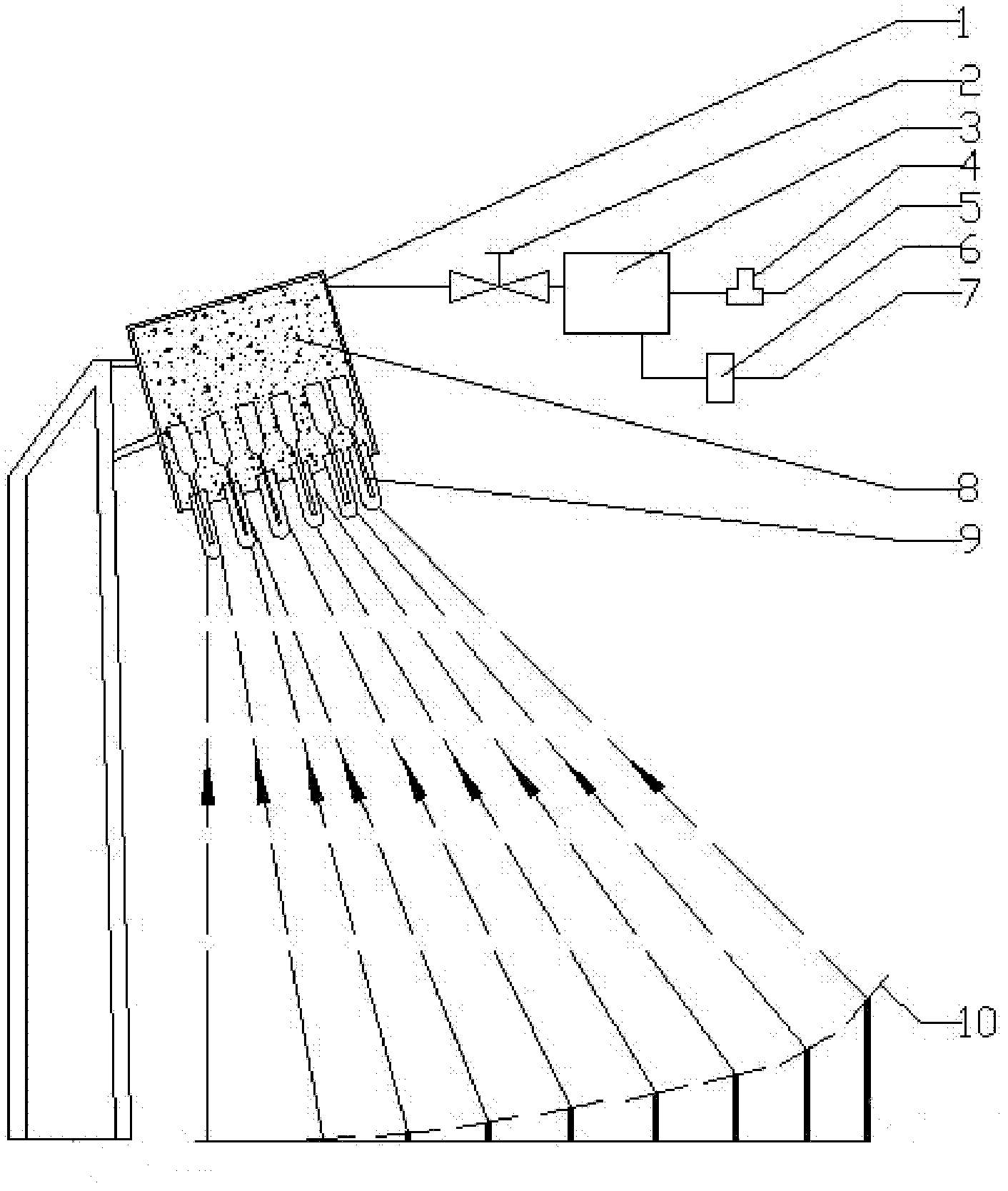

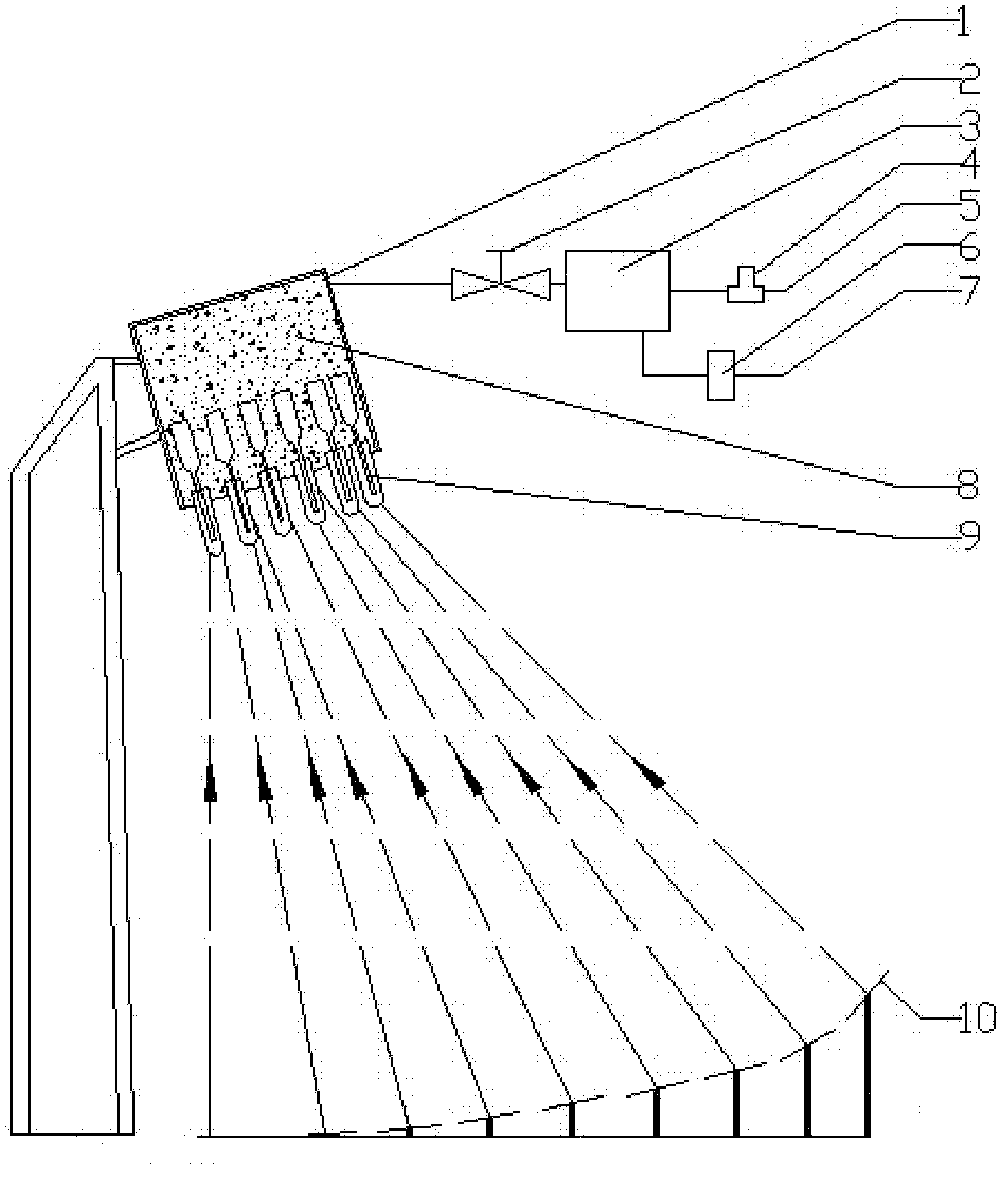

[0030] Such as figure 1 As shown, the present embodiment utilizes the device of solar energy pyrolysis waste and old plastics to make fuel oil, comprises pyrolysis furnace 1, 200 solar concentrating mirrors 10, high-temperature heat pipe 9 and fractionation tower 3; The lower end of cracking furnace 1, high-temperature heat pipe 9 is positioned at the focal point of solar concentrator 3; Cracking furnace 1 is connected with the input port of check valve 2, fractionating tower 3 successively by pipeline; Described fractionating tower 3 is provided with two output ports, One of the output ports is connected to the fuel oil outlet 5 through the cut-off valve 4, and the other output port is the tail gas outlet 7, and the tail gas treatment device 6 equipped with activated carbon is arranged on the tail gas outlet 7. The area of the solar concentrator is 0.1m 2 ~2m 2 They are arranged around the cracking furnace in sequence.

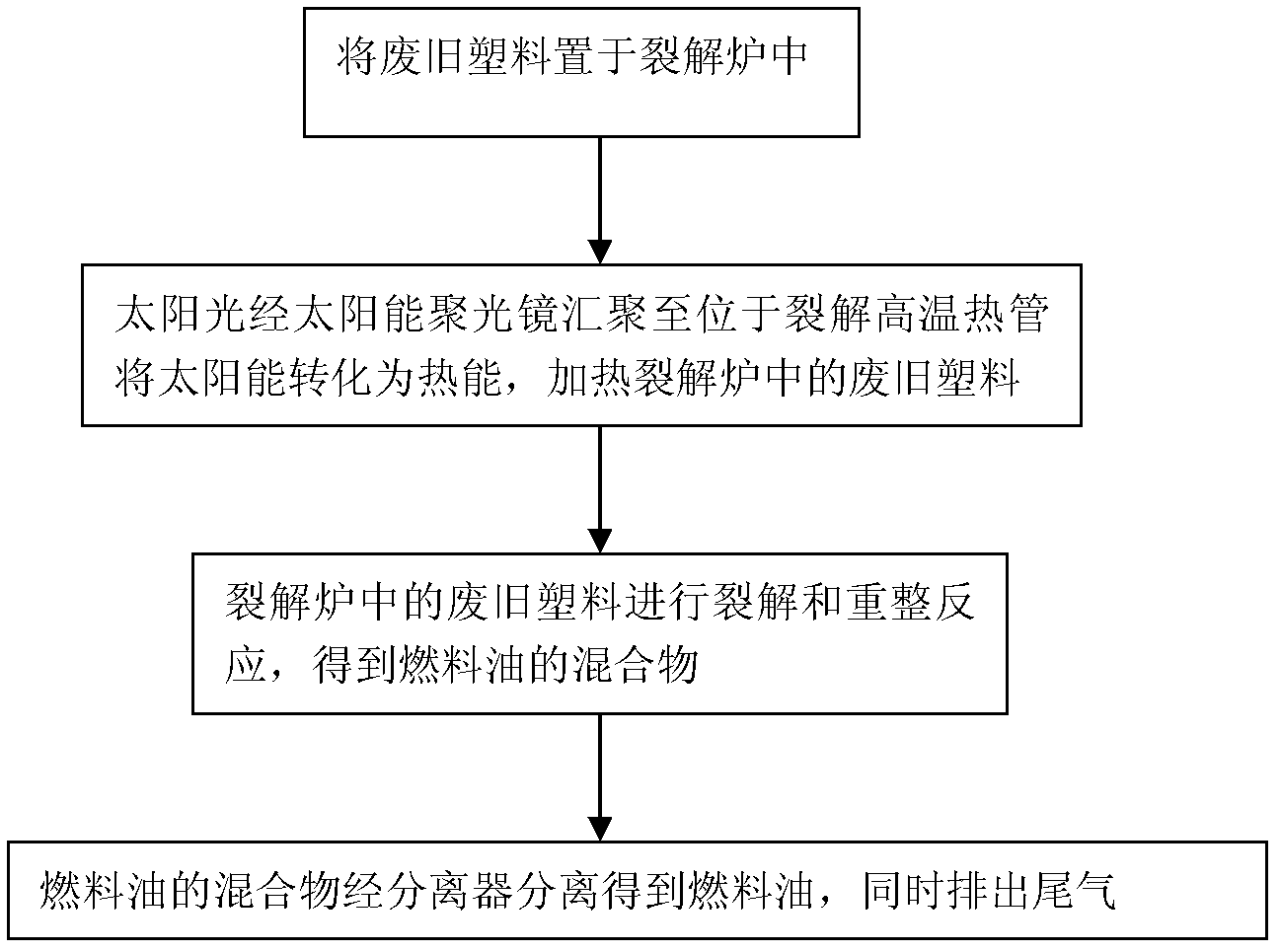

[0031] Such as figure 2 Shown, the present embod...

Embodiment 2

[0037] This embodiment utilizes the device of solar energy cracking waste plastics to make fuel oil, comprising cracking furnace, 100,000 solar concentrating mirrors, high-temperature heat pipes and fractionation towers; Located on the focal point of the solar concentrator; the cracking furnace is connected with the check valve and the input port of the fractionation tower in turn through the pipeline; the fractionation tower is provided with two output ports, one of which is connected to the fuel oil outlet through a shut-off valve, and the other The output port is the tail gas outlet, and the tail gas treatment device equipped with activated carbon is arranged on the tail gas outlet. The area of the solar concentrator is 0.1m 2 ~2m 2 They are arranged around the cracking furnace in sequence.

[0038] The present embodiment utilizes the method for solar energy pyrolysis waste and old plastics fuel oil, comprises the following steps:

[0039] (1) 1.5 tons of waste plastic...

Embodiment 3

[0044] This embodiment utilizes the device of solar energy cracking waste plastics to make fuel oil, comprises cracking furnace, solar concentrator, high-temperature heat pipe and fractionation tower; A plurality of high-temperature heat pipes with an outer diameter of 47 mm are evenly arranged at the lower end of the cracking furnace, and the high-temperature heat pipe is located at the solar concentrator on the focal point; the cracking furnace is connected with the check valve and the input port of the fractionation tower successively through the pipeline; the fractionation tower is provided with two output ports, wherein one output port is connected to the fuel oil outlet by a shut-off valve, and the other output port is The tail gas outlet is equipped with a tail gas treatment device equipped with activated carbon. In the present embodiment, the solar concentrator is a dish-shaped solar concentrator with an area of 9m 2 .

[0045] The method that the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com