Textile having negative ion and far-infrared functions

A negative ion far-infrared, textile technology, applied in the direction of textiles and papermaking, plant fiber, fiber treatment, etc., can solve the problems of poor stability, achieve the effect of increasing the concentration of negative ions, enhancing the immunity of the human body, and improving the ability to release negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

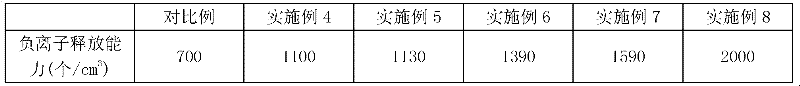

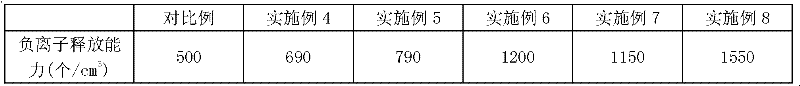

Examples

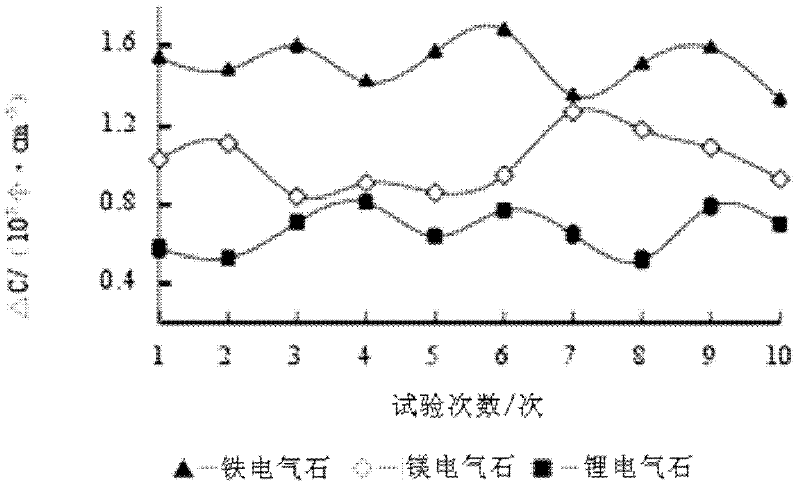

Embodiment 1

[0021] The preparation method includes the following steps:

[0022] a. Prepare anion coating agent, add dropwise crosslinking agent (melamine) aqueous solution and anion additives to polyacrylate adhesive (acrylate modified waterborne polyurethane), stir evenly to obtain; the crosslinking agent The weight percentage of the aqueous solution of the polyacrylate adhesive is 1%, and the weight percentage of the negative ion additive to the polyacrylate adhesive is 1%; the weight ratio of the negative ion additive including 4000 mesh is 12:1 :1 Magnesium tourmaline powder, serpentine powder and hornblende powder;

[0023] b. Coating operation, quickly and uniformly scrape the prepared anion coating agent on the base cloth, and repeat the scraping until the anion coating agent completely covers the pores of the base cloth; then place it at 105°C and bake for 5 minutes to get the result The textiles with the effect of negative ion far infrared. The base cloth used is pure cotton cloth ...

Embodiment 2

[0025] The preparation method includes the following steps:

[0026] a. Prepare anion coating agent, add dropwise crosslinking agent (melamine) aqueous solution and anion additives to polyacrylate adhesive (acrylate modified waterborne polyurethane), stir evenly to obtain; the crosslinking agent The weight percentage of the aqueous solution of the polyacrylate adhesive is 1%, and the weight percentage of the negative ion additive to the polyacrylate adhesive is 1%; the weight ratio of the negative ion additive including 4000 mesh is 12:1 :1 lithium tourmaline powder, serpentine powder and hornblende powder;

[0027] b. Coating operation, quickly and uniformly scrape the prepared anion coating agent on the base cloth, and repeat the scraping until the anion coating agent completely covers the pores of the base cloth; then place it at 105°C and bake for 5 minutes to get the result The textiles with the effect of negative ion far infrared. The base cloth used is pure cotton cloth wi...

Embodiment 3

[0029] The preparation method includes the following steps:

[0030] a. Prepare anion coating agent, add dropwise crosslinking agent (melamine) aqueous solution and anion additives to polyacrylate adhesive (acrylate modified waterborne polyurethane), stir evenly to obtain; the crosslinking agent The weight percentage of the aqueous solution of the polyacrylate adhesive is 1%, and the weight percentage of the negative ion additive to the polyacrylate adhesive is 1%; the weight ratio of the negative ion additive including 4000 mesh is 12:1 :1 of iron tourmaline powder, serpentine powder and hornblende powder;

[0031] b. Coating operation, quickly and uniformly scrape the prepared anion coating agent on the base cloth, and repeat the scraping until the anion coating agent completely covers the pores of the base cloth; then place it at 105°C and bake for 5 minutes to get the result The textiles with the effect of negative ion far infrared. The base cloth used is pure cotton cloth wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com