Preparation method for mixed pulp of wheat straw and reed

A technology for mixing pulp and reed, which is applied in the field of preparation of wheat straw and reed mixed pulp, can solve problems such as affecting the extraction probability of black liquor, affecting the normal production of enterprises, and difficulty in filtering water of the pulp, so as to expand the market share and increase the wet weight. , easy-to-filter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

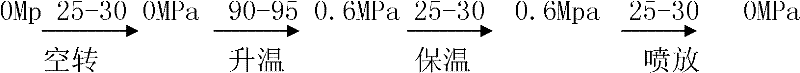

[0019] The preparation of wheat straw and reed mixed pulp of the present invention mainly adopts the caustic soda pulping method to obtain by adopting the ratio of 7:3~4:6, and the specific method is:

[0020] Wheat straw and reed are prepared by dry-wet combination method: that is, wheat straw and reed are respectively cut to the range required by the method through a knife-roller mower, and after dedusting and impurity removal by a claw dust collector, the ratio is 7:3 to 4:6. It is mixed and sent to the hydraulic shredder for crushing and washing of the raw materials. The washed grass and reed mixed pieces are pumped into the oblique screw dehydrator for dehydration treatment. The treated grass pieces enter the pin drum meter. The excess grass and reed mixed pieces are sent back to the hydraulic grass cutter by the return screw. After the above-mentioned process, the length of the grass slices and reed slices obtained from wheat straw and reed is 40-60mm, the water content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com