Technology for preparing high cover performance calcined kaolin through coal gangue

A technology of calcining kaolin and coal gangue, which is applied in the direction of inorganic chemistry, silicon compounds, chemical instruments and methods, etc., can solve problems such as unsatisfactory covering performance, achieve the effect of improving particle size distribution range, reducing cost and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

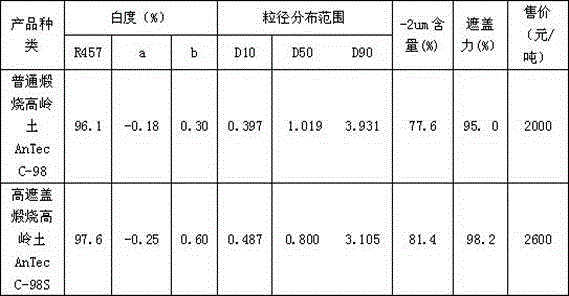

Image

Examples

Embodiment 1

[0029] Embodiment 1. A process for preparing calcined kaolin with high covering performance from coal gangue, the steps are: raw coal gangue → primary iron removal → crushing → mineral processing → screening → secondary iron removal → dry grinding → tap water pulping → Iron removal→wet grinding→twice iron removal→drying→disintegration→calcination→disintegration→product.

[0030] First of all, before crushing, large pieces of quartz, carbon blocks and other impurities mixed in coal gangue are removed by hand to ensure the purity of materials before crushing, and the broken coal mixed in gangue is removed by double-layer vibrating screen. Electromagnetic iron remover and permanent magnet iron remover are installed before and after for primary iron removal and secondary iron removal, which not only protects the equipment but also facilitates iron removal.

[0031]When making pulp, increase the solid content of the slurry to 53-57%. In the wet grinding section, add 100 mesh, 325 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com