Movable turnout platform used for shield tunnel

A mobile turnout technology, applied in the field of movable turnout platform, can solve the problems affecting the progress of the construction period, long downtime, waste, etc., and achieve the effect of saving construction investment and safe and reliable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

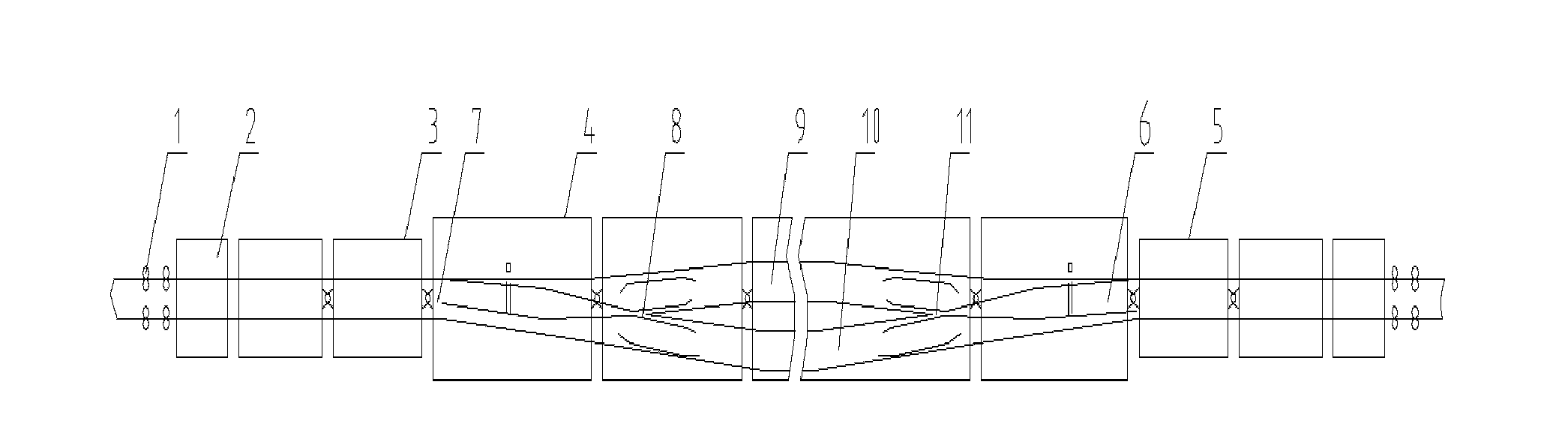

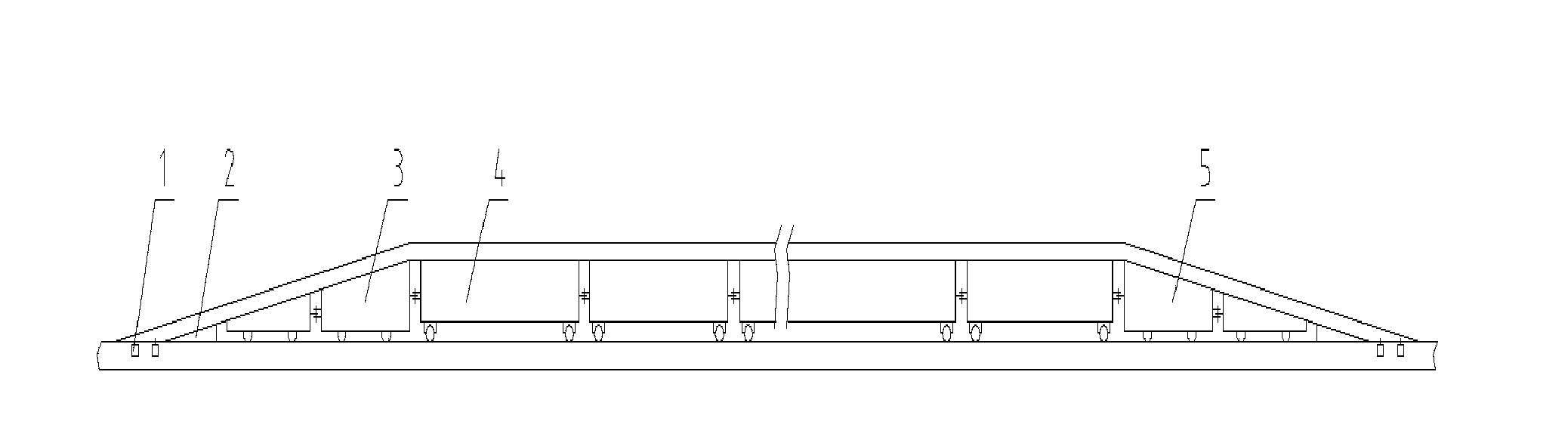

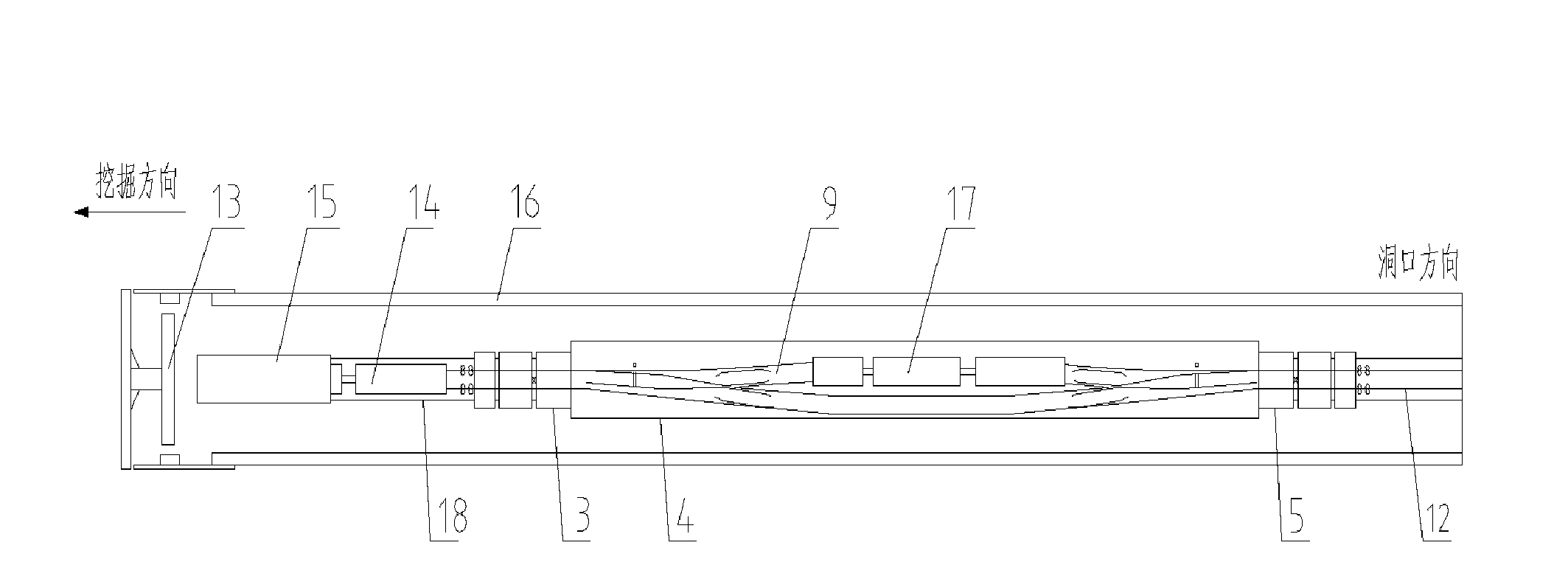

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a movable turnout platform for shield tunnels consists of track guide wheel 1, wear-resistant steel plate 2, slope trolley I3, plane trolley 4, slope trolley II5, track D6, track A7, single Composed of open turnout I8, track B9, track C10, and single turnout II11, the front and rear track guide wheels 1 and wear-resistant steel plates 2 are respectively installed on the contact ends of track D6 and track A7 connected to the middle track 12 for steering; ramp platform Car I3, plane trolley 4 and slope trolley II5 are connected by pin shafts to realize the turning action of the movable turnout platform used in shield tunnels; track B9 and track C10 are laid side by side; single-opening turnout I8, The switch machinery of single turnout II11 realizes the operation of merging and splitting; the tunnel track is arranged in parallel with four tracks, and the supporting trolley behind the shield machine 13 trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com