Gas passage and combustion chamber structure of three-valve engine

A combustion chamber and engine technology, used in engine components, combustion engines, machines/engines, etc., can solve the problems of low flame propagation speed, low air intake flow coefficient, and large heat transfer area, and achieve fast flame propagation speed and high heat transfer. High air flow coefficient and the effect of reducing valve noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

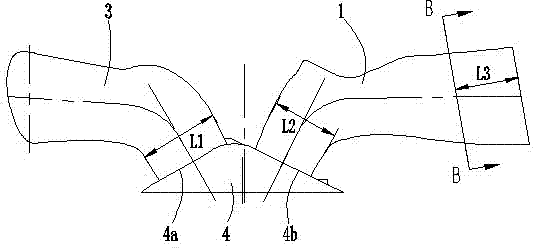

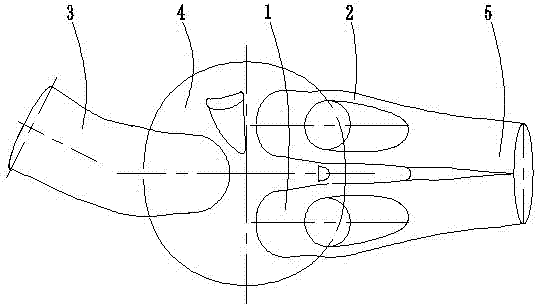

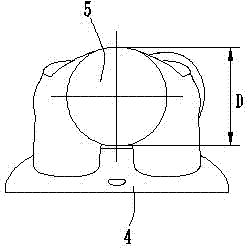

[0013] Such as figure 1 , figure 2 , image 3 As shown, the cylinder head of the three-valve engine is provided with a first intake port 1, a second intake port 2, an exhaust port 3 and a combustion chamber 4. Wherein, the lower end of the combustion chamber 4 is open, and the outline of the lower port of the combustion chamber 4 is approximately circular. The inner top wall of the combustion chamber 4 is a double-slope structure, such as figure 1 The one shown on the left is the first slope 4a, the one on the right is the second slope 4b, and the deepest depth of the combustion chamber 4 is 9-13mm. The first slope 4a and the second slope 4b have a smooth transition through a curved surface, and there is an included angle of 120-128° between the first slope 4a and the second slope 4b. In this embodiment, the first slope 4a and the second slope The angle between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com