Micropore measurer based on orthogonal two-dimensional micro-focus collimation and method

A length measuring device and micro-focus technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of two-dimensional measurement error, insufficient detection ability of two-dimensional displacement direction, poor real-time performance of the detection system, etc., to eliminate correlation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

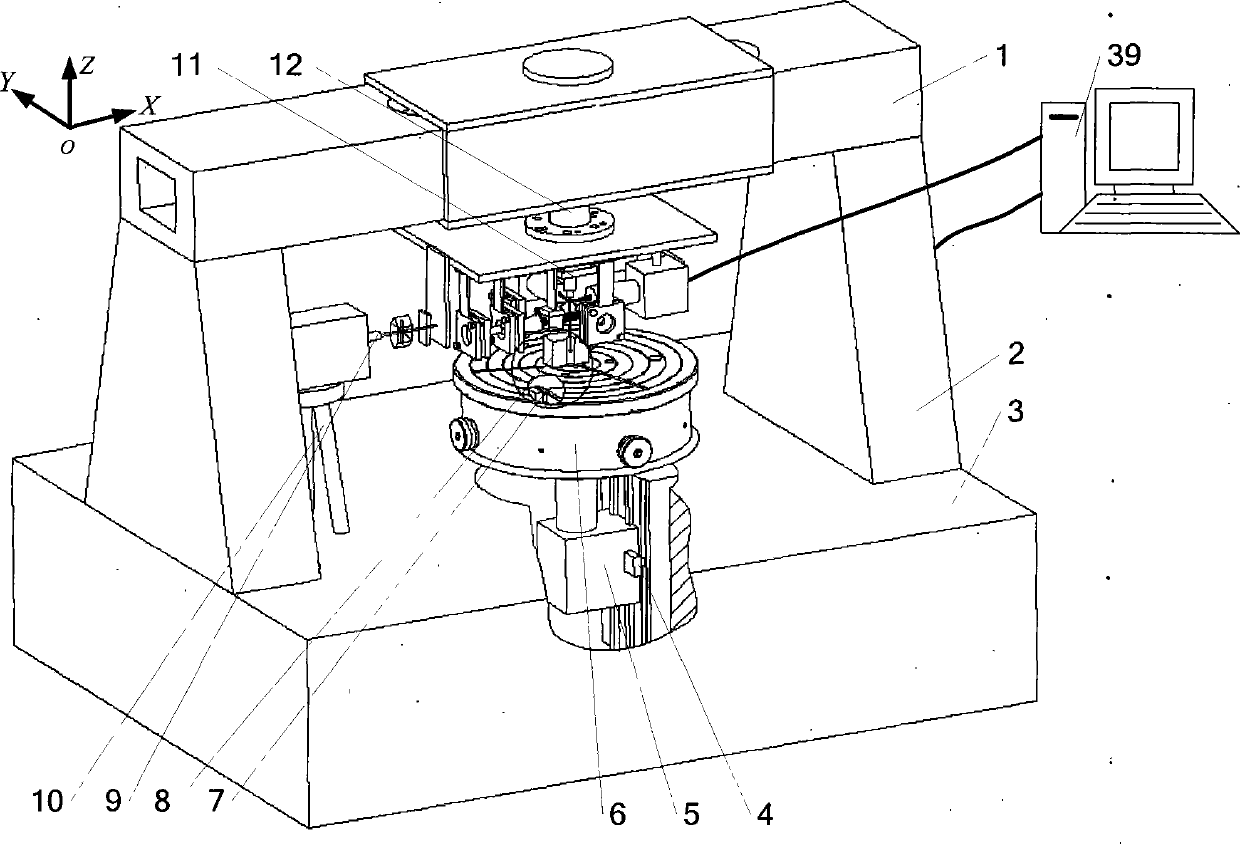

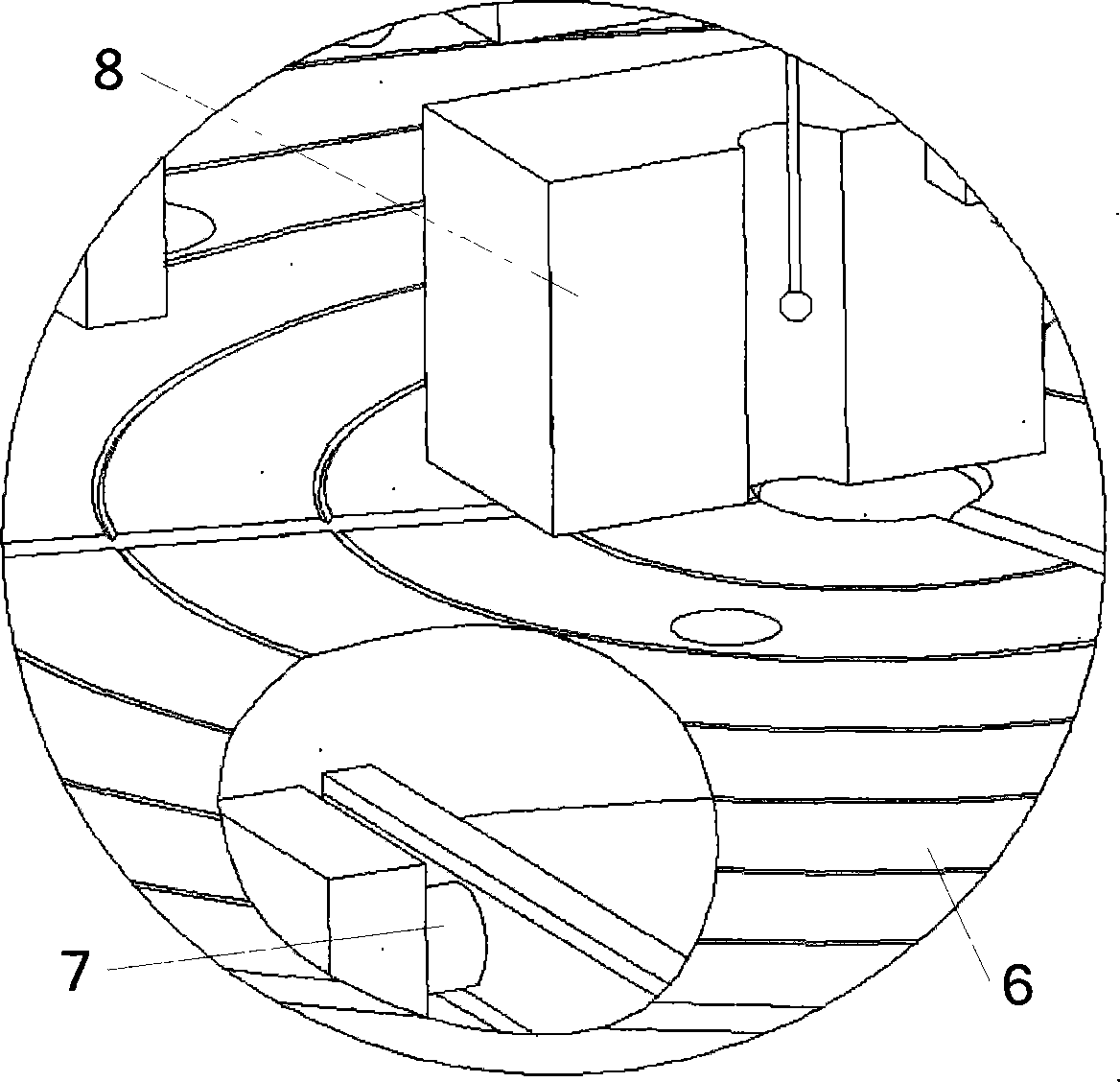

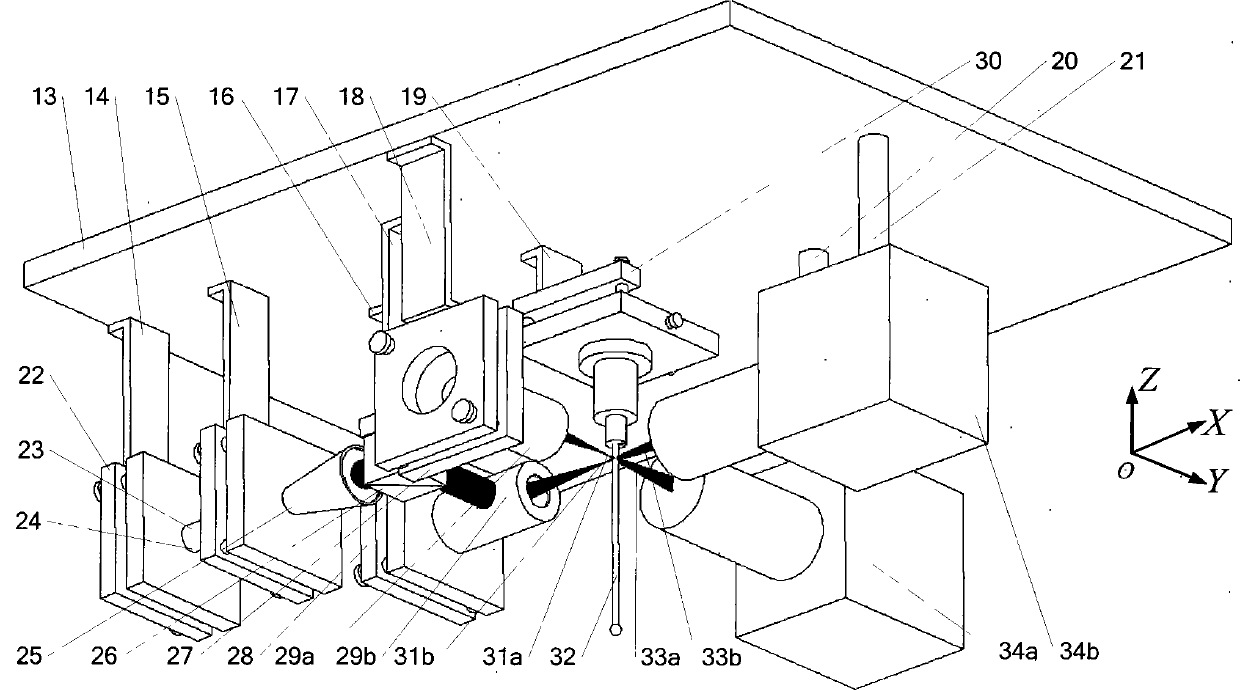

[0034]A microhole measurement device based on orthogonal two-dimensional microfocus alignment, two support frames 2 are assembled on the support base 3, a beam 1 is assembled on the support frame 2, and Z-direction movement is assembled in the groove of the support base 3 Part 5, the Z-direction length measuring device 4 is assembled on the side of the Z-direction moving part 5, and the worktable 6 is fixed above the Z-direction moving part 5, and the Y-direction length measuring device 7 is assembled inside the workbench 6, connected by a sensor Component 12 fixes and hangs the measuring sensor 11 on the middle position of the beam, and the dual-frequency laser 35, polarization beam splitter group 36, and λ / 4 glass slide 37 of the X-direction length measuring device 9 are assembled on the left side of the support base 3 through the tripod 10. In the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com