Method and device for measuring concentration of coal powder

A measurement method and technology of pulverized coal, which can be used in measuring devices, analysis of suspensions and porous materials, instruments, etc., can solve problems such as inaccurate measurement of pulverized coal concentration, and achieve the effect of simple method and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

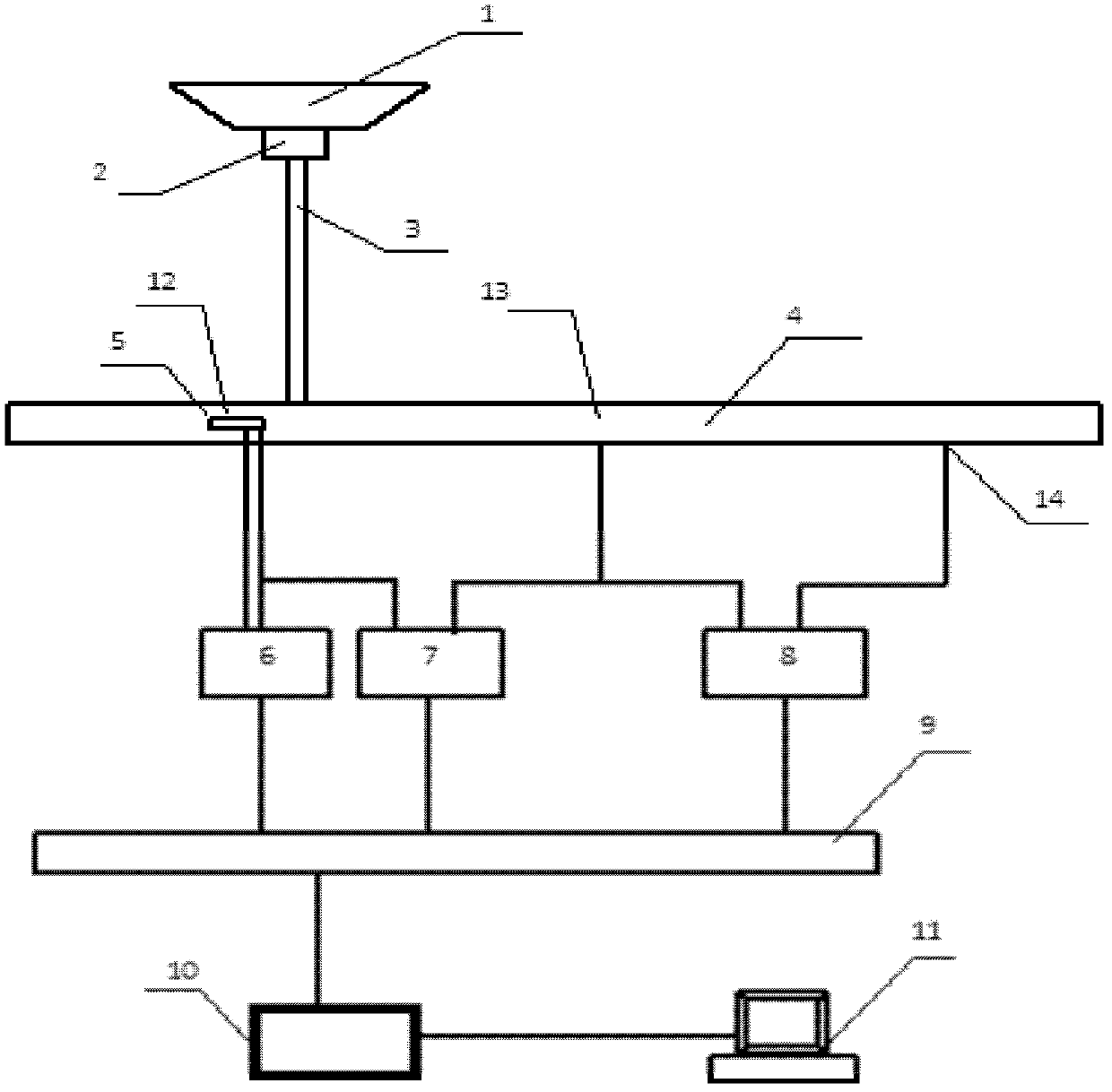

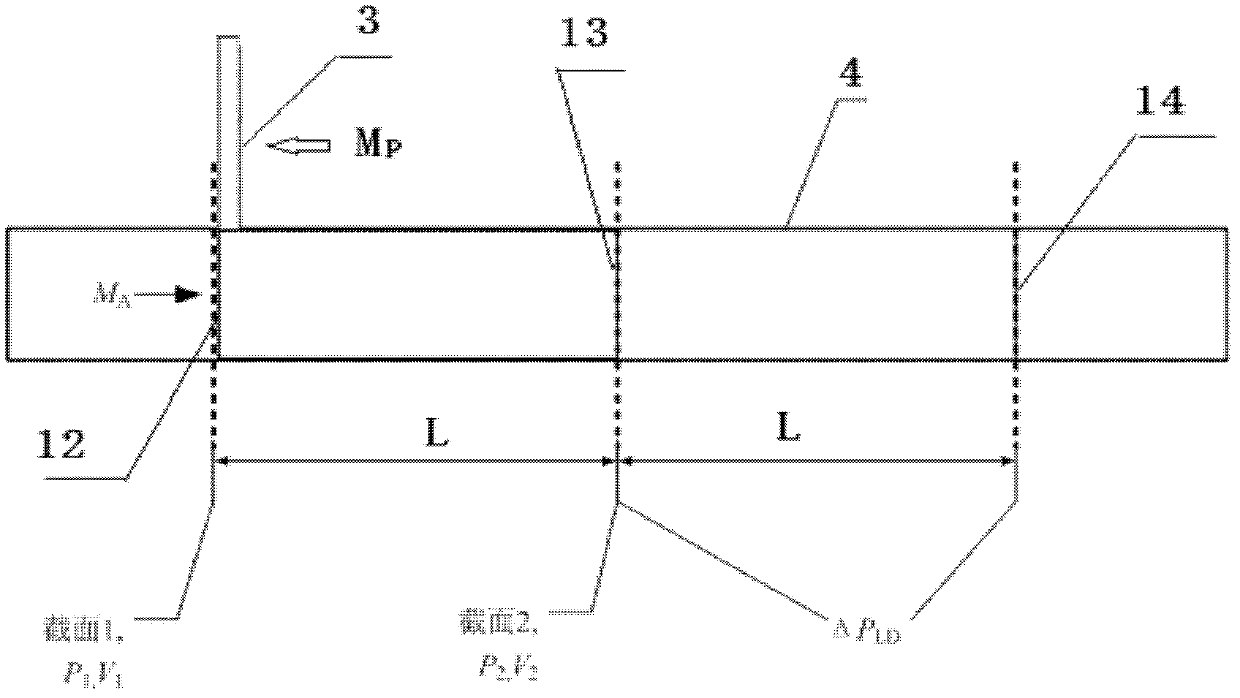

[0027] Coal concentration measurement method, combined with figure 1 , figure 2 , in the picture, 1-powder bin, 2-powder feeder, 3-powder lower pipe, 4-primary air duct, 5-total pressure-static pressure measuring element, 6-differential pressure transmitter I, 7-differential pressure Transmitter II, 8-differential pressure transmitter III, 8-data acquisition board, 10-data acquisition instrument, 11-computer, 12-measuring point I, 13-measuring point II, 14-measuring point III. Include the following steps:

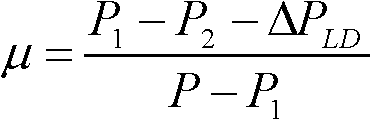

[0028] 1) On the primary air duct, select the airflow parameter measurement point I before the pulverized coal is mixed and the airflow parameter measurement point II after mixing. At the place where the airflow is stable, the airflow parameter measurement point II after mixing is set at the point where the velocity of the pulverized coal particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com