A kind of CE-based composite catalyst suitable for hydrogen sulfide catalytic reduction desulfurization and denitrification process and preparation method thereof

A composite catalyst, desulfurization and denitrification technology, applied in the field of Ce-based composite catalyst and its preparation, can solve the problems of low conversion rate at low temperature, high energy consumption at high temperature section, and inability to remove, achieve high conversion rate, simplify process flow, The effect of high economic value and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

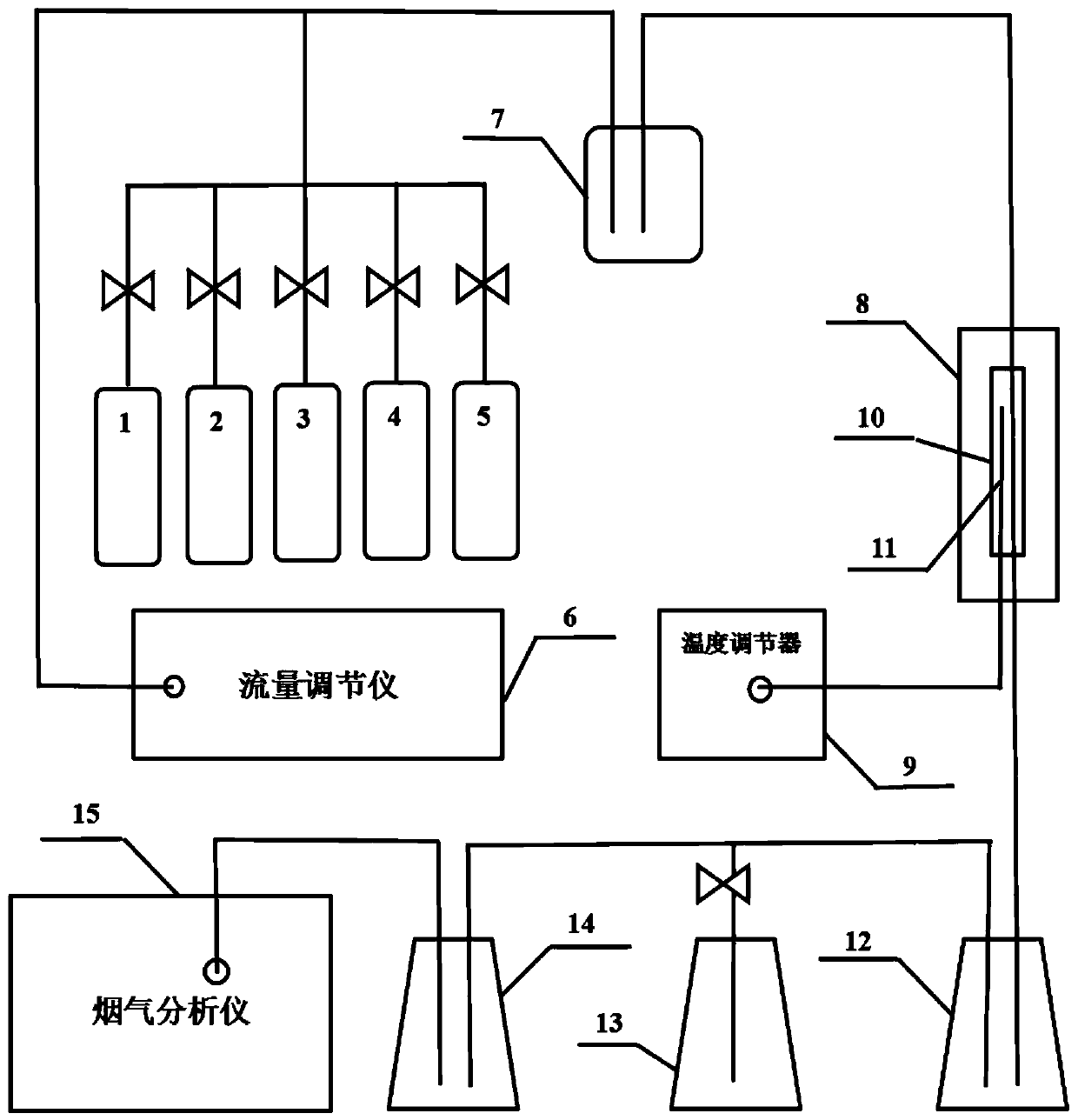

Image

Examples

preparation example Construction

[0033] A preparation method of a Ce-based composite catalyst suitable for hydrogen sulfide catalytic reduction desulfurization and denitrification process includes the following steps:

[0034] 1) Prepare the composite carrier Al first 2 o 3 -TiO 2 ;

[0035] 2) Post-preparation of the composite catalyst CeO 2 / Al 2 o 3 -TiO 2 .

[0036] Preferably, in step 1), the Al 2 o 3 -TiO 2 It is prepared by sol-gel method with aluminum salt and titanate.

[0037] Preferably, in step 1), the aluminum salt is aluminum nitrate; the titanate is tetrabutyl titanate; the molar ratio of aluminum nitrate to tetrabutyl titanate is 2:1; further , the aluminum nitrate is Al(NO 3 ) 3 9H 2 O; The tetrabutyl titanate is Ti(OC 4 h 9 ) 4 .

[0038] Preferably, in step 2), the composite catalyst CeO 2 / Al 2 o 3 -TiO 2 It uses cerium salt and composite carrier Al 2 o 3 -TiO 2 Prepared by isometric impregnation.

[0039] Preferably, in step 2), the cerium salt is cerium nitrate; f...

Embodiment

[0042] a-Composite carrier AT (Al 2 o 3 -TiO 2 ) preparation method:

[0043] (1) In a 250ml beaker, add 2.4molC in sequence 2 h 5 OH, 0.9molCH 3 COOH, and 1.8 mol of deionized water, and then uniformly stirred for 1 min until completely mixed uniformly to prepare a mixed solvent.

[0044] (2) Weigh 0.2mol of Al(NO 3 ) 3 9H 2 O, then pour it into the mixed solvent prepared above, and stir until it is completely dissolved.

[0045] (3) Add 0.1mol of Ti(OC 4 h 9 ) 4 Slowly add the above-mentioned dissolved Al(NO 3 ) 3 9H 2 in a mixed solution of O. After the addition is complete, it is stirred and allowed to stand until a single homogeneous mixed solution is formed.

[0046] (4) Put the above solution into a magnetic stirrer for heating and stirring until the solution is completely solidified into a white jelly.

[0047] (5) Aging the resulting white jelly for 12 hours, and then drying it in an oven at 110°C until white particles are formed.

[0048] (6) Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com