Optical fiber connector and assembly method thereof

A fiber optic connector and assembly method technology, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of incompetence and small size of fiber optic connectors, and achieve the effect of reducing the overall size and increasing the installation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

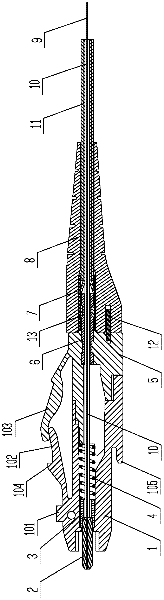

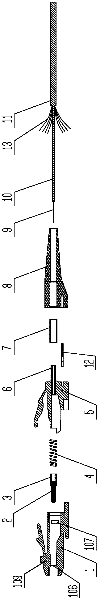

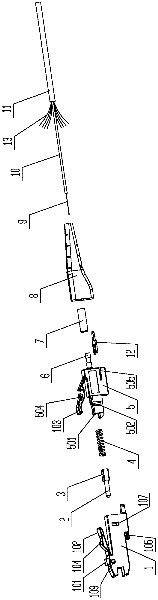

[0061] Such as Figures 1 to 8 As shown, a specific embodiment of the optical fiber connector of the present invention is given. The connector includes a connector housing, which is formed by inserting and snapping the front housing 1 and the rear housing 5, and the rear housing 5 is inserted and fastened. The cross-section of the insertion part of the housing 5 is an inverted U-shaped structure, and the two outer surfaces of the inverted U-shaped structure are respectively provided with front housing undercuts 502, corresponding to the two side walls of the front housing 1, respectively provided with button positions 107 , when the rear case 5 is inserted into the front case 1, the front case undercut 502 can pop out from the buckle position 107 to form a buckle. Shrink inward, on the other hand, when the front shell undercut 502 reaches the buckle position 107, it has elastic force to pop out to form a buckle. The front end of the front shell 1 has a through hole 106, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com