Disk-shaped suspension porcelain or glass composite insulator

A composite insulator and glass technology, applied in the direction of suspension/strain insulator, etc., can solve the problems of reducing effective creepage distance, complicated manufacturing process, difficult to obtain electromechanical performance, etc., achieve enhanced anti-pollution flashover ability, and improve pollution flashover voltage , enhance the effect of water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings.

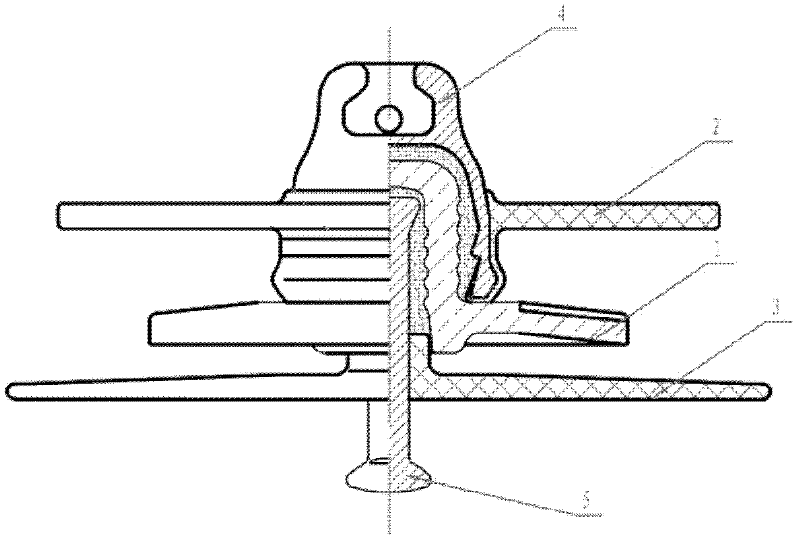

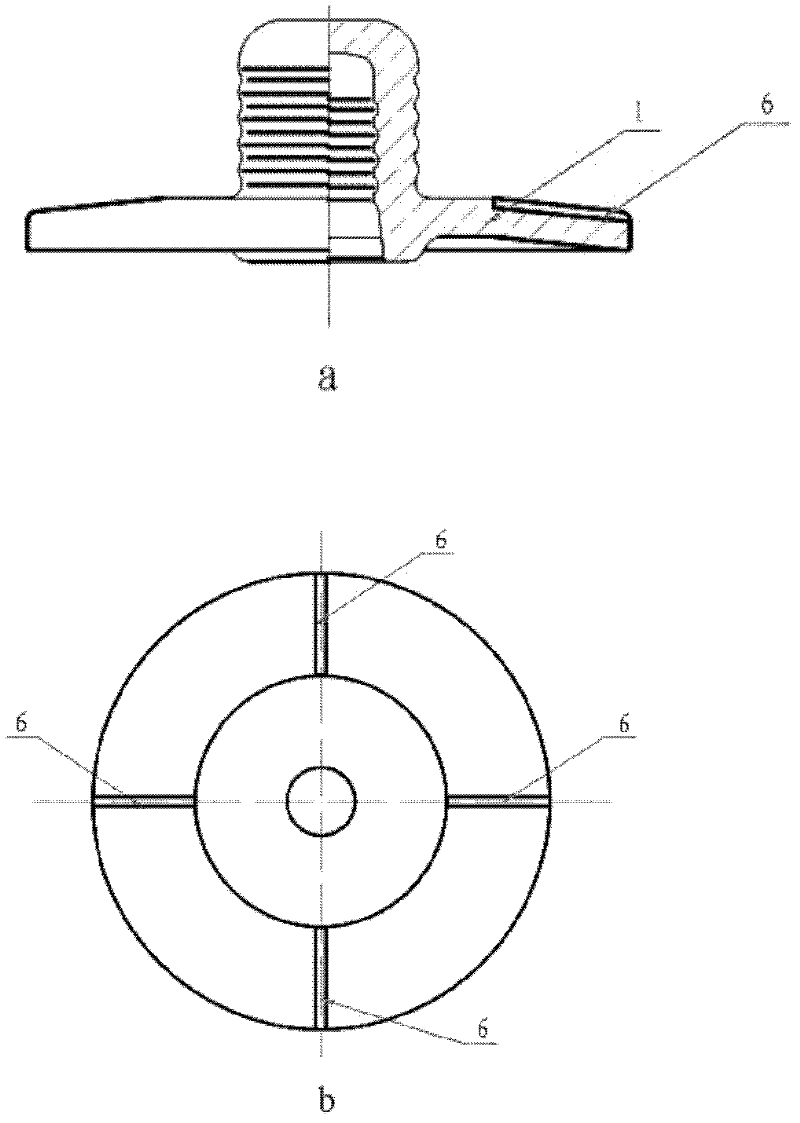

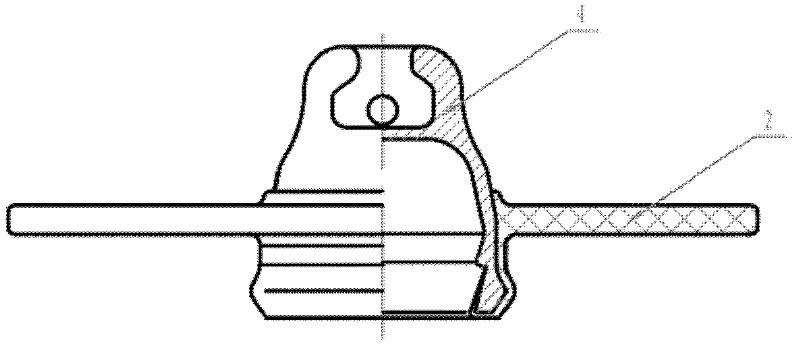

[0038] refer to figure 1 The porcelain or glass piece 1 of the present invention has an iron cap 4 on the upper part and a steel foot 5 on the lower part. The lower part of the iron cap 4 is molded or injected to have an integral combined barrier 2, and the middle and lower part of the steel foot 5 is molded or injection-molded as an integral combination. Form barrier 3. Firstly, press molding or injection molding the overall barrier on the iron cap and steel feet respectively, and then according to the traditional assembly procedure of disc-shaped suspended porcelain or glass insulators, the porcelain or glass parts and the iron cap with integral barrier, The steel feet are connected to complete the whole process of factory production of disc suspension porcelain or glass composite insulators. Manufactured in the factory, compression molding or injection molding ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com