Building-block-combined-type high power transformer

A combined, high-power technology, applied in the direction of transformers, fixed transformers, transformer/inductor cores, etc., can solve problems such as expensive production costs, transformer overheating, primary coil temperature rise, etc., to save eddy current losses, reduce costs, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

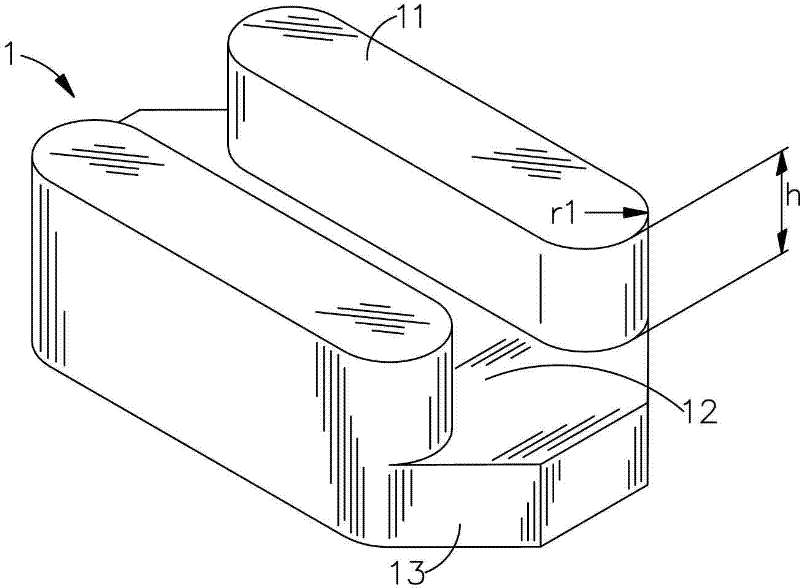

[0038] see figure 1 As shown, it is a schematic diagram of a three-dimensional structure of a preferred embodiment of a single iron core body of the present invention. The iron core body 1 of the present invention has a polygonal shape. In a preferred embodiment of the present invention, the iron core body 1 is an octagonal shape and is made of a conductive material. The two sides of this iron core body 1 respectively have a side wing part 11, and the two ends of the side wing part 11 are in the shape of an arc with a curvature radius r1, and a slot 12 is formed between the aforementioned two side wing parts 11, and the slot 12 The top surface of and the top surface of the side wing portion 11 are separated by a height h. Two ends of the iron core body 1 respectively have at least one inclined slot 13 .

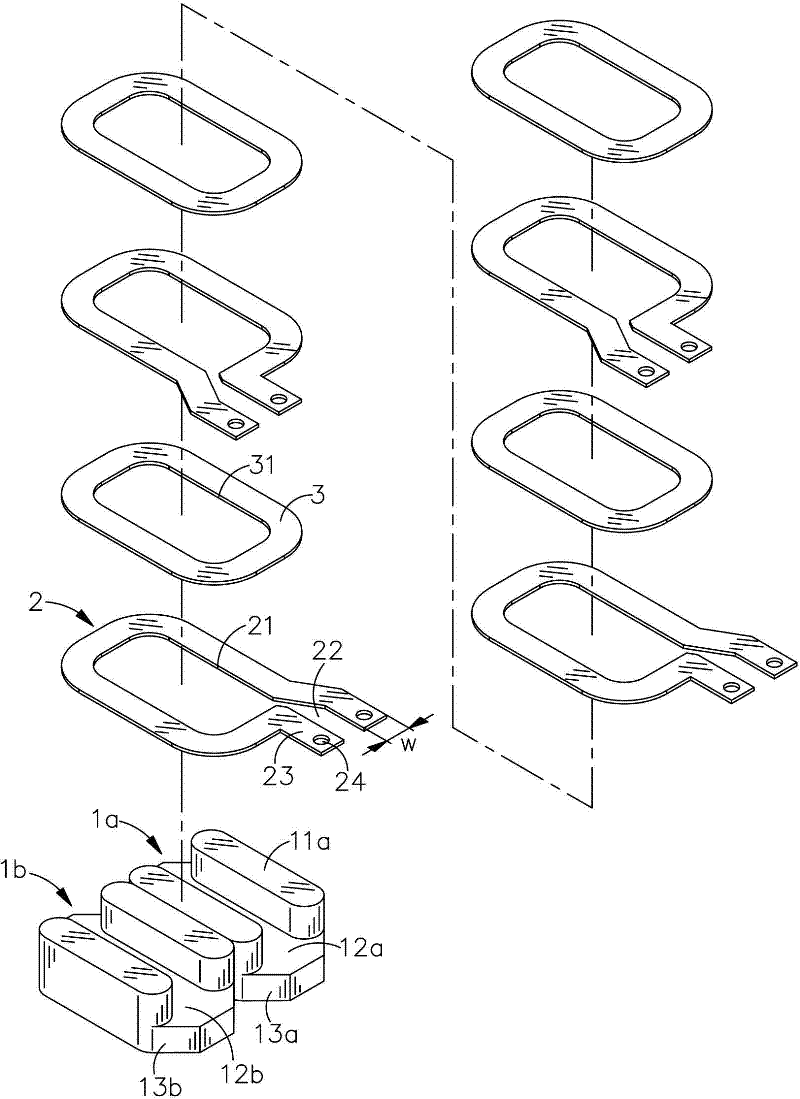

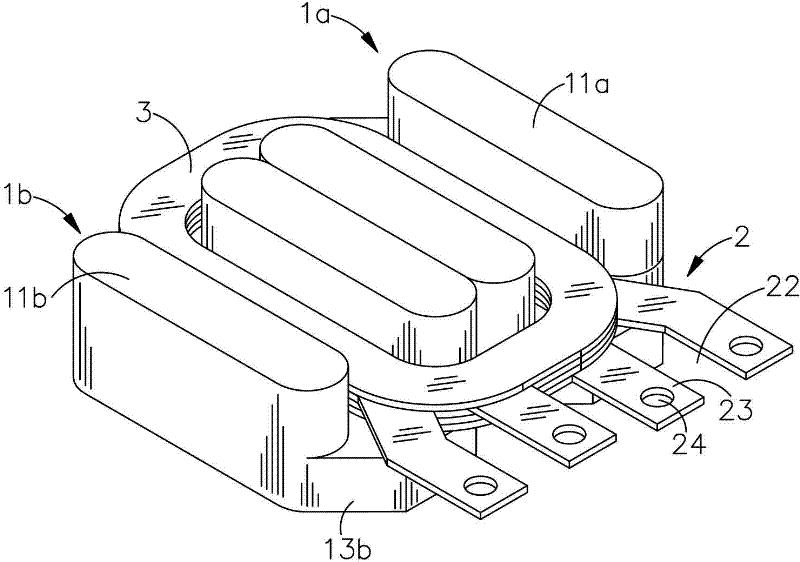

[0039] Since the building block combined high-power transformer of the present invention is formed by arranging and combining a plurality of aforementioned iron core bodies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com