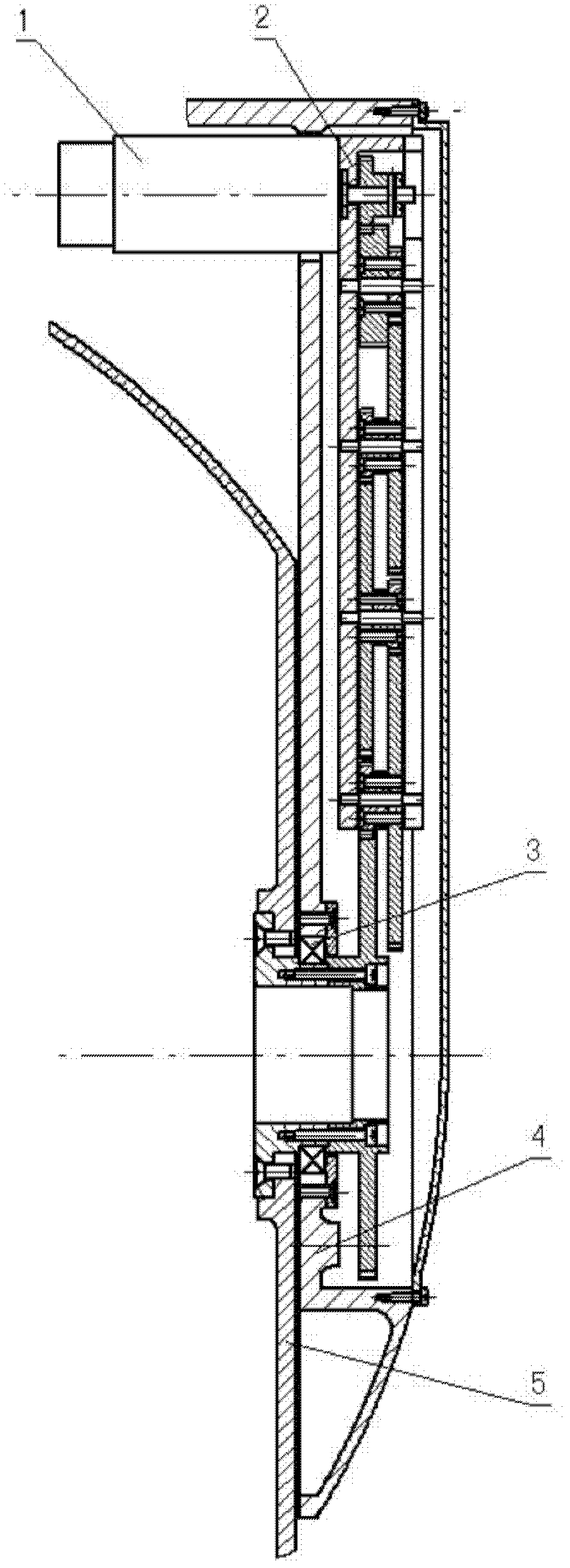

Airborne photoelectric-platform outer frame elimination clearance torque motor driving shafting module

A technology of torque motor and photoelectric platform, which is applied in the field of aviation optoelectronics, can solve the problems that the drive structure does not have modular characteristics, affects the servo control accuracy of photoelectric platform, and is not suitable for airborne equipment, etc., and achieves the elimination of gear transmission gap and high practicality Value, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

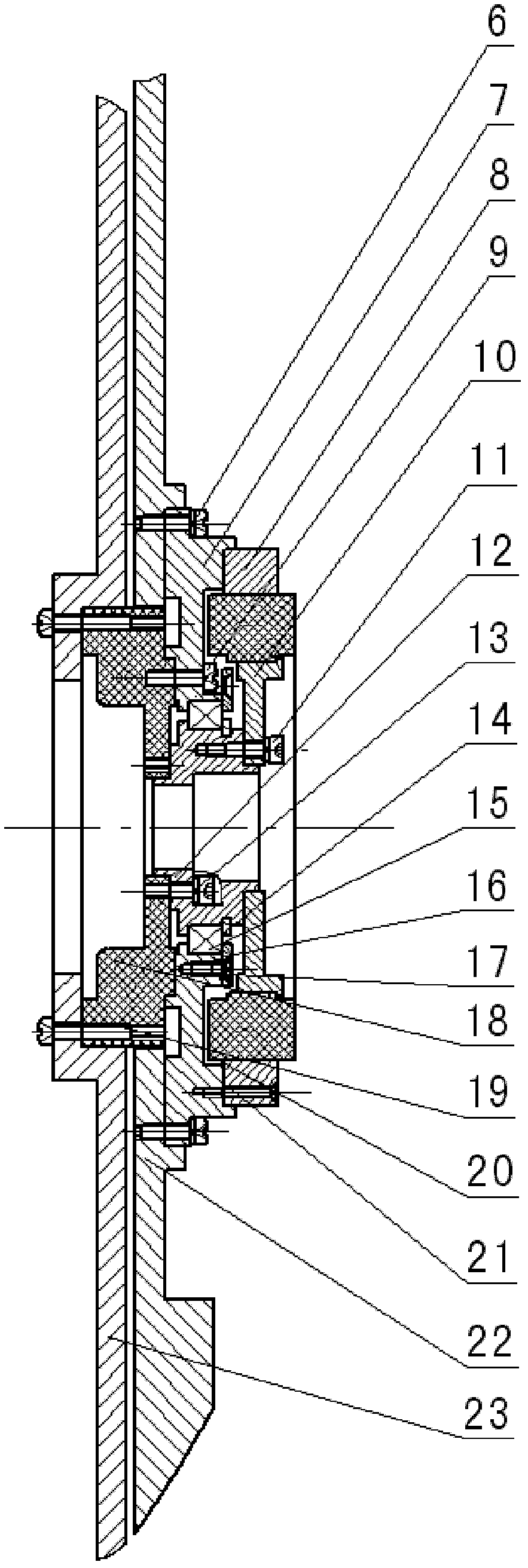

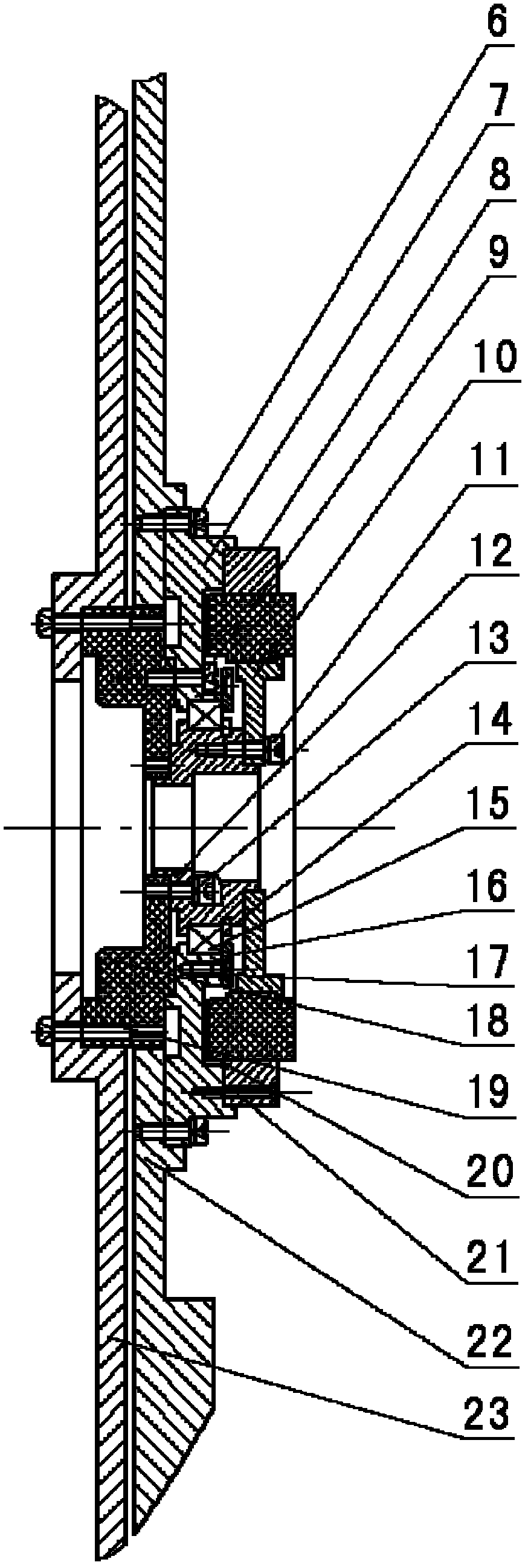

[0013] The invention according to figure 2 The structure shown is implemented. Among them, the torque motor seat 7 is made of titanium alloy material TC4, the torque motor shaft 10 and the bearing cover 16 are made of steel 45#, the input shaft 12 of the harmonic reducer is made of steel 40Cr, the shaft end retaining ring 14 and the bearing 15 are standard parts, and the harmonic The reducer 18 is purchased from Beijing Beicheng Xinkong Servo Technology Co., Ltd. SHD-17-50-2sh harmonic reducer, the torque motor stator 8 and the torque motor rotor 20 are purchased from Beijing Aimate Technology Co., Ltd. QT3832 torque motor. The assembly process is as follows: connect the outer ring of the bearing 15 with the torque motor base 7, connect the inner ring of the bearing 15 with the input shaft 12 of the harmonic reducer, and fix the bearing cover 16 on the torque motor base 7 through the first countersunk screw 17, and the shaft The end retaining ring 14 is installed in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com