Driving power supply of ballast type LED (Light-Emitting Diode) lamp

A technology for LED lamps and driving power, applied in electric light sources, electric lamp circuit layout, light sources, etc., can solve problems such as large current harmonics and reactive power, grid pollution, and difficulty in supplying circuits, and achieve high working reliability, The effect of long service life and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

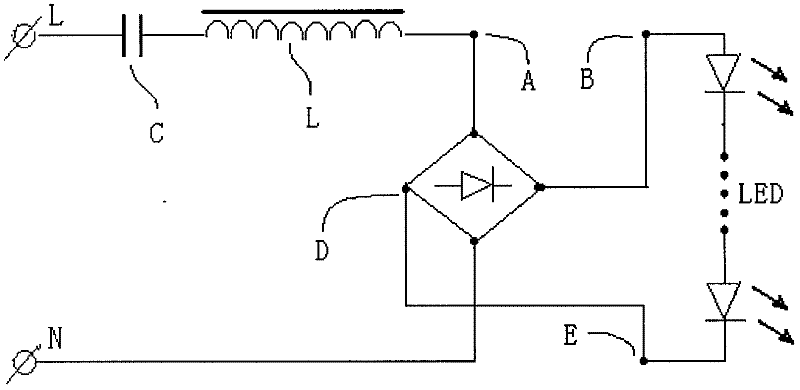

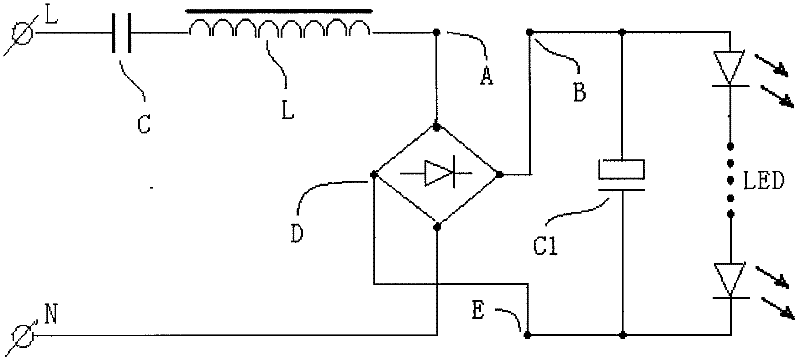

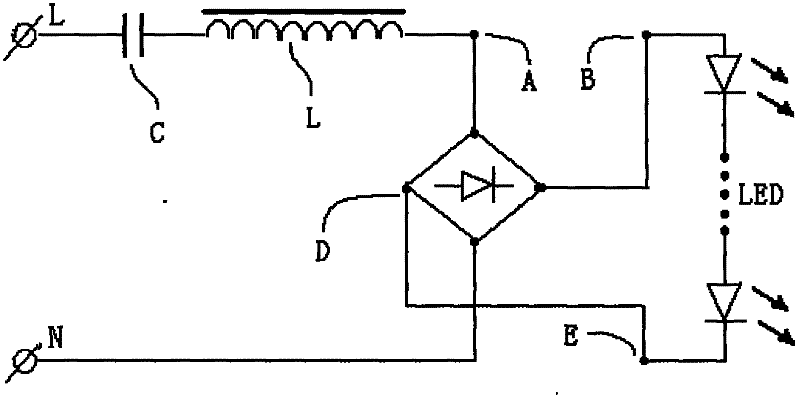

[0011] see figure 1 , the schematic diagram of the circuit structure of the driving power supply of the ballast LED lamp of the present invention, including capacitor (C), low consumption (low drop) inductance ballast (L), said low consumption inductance ballast ( A rectification element (D) is connected between the A terminal of L) and the input N terminal; the said LED lamp is connected between two points of the rectification output terminals (B) and (E).

[0012] when figure 1 After the (L) and (N) terminals of the ballast LED lamp drive power circuit are connected to the 220V mains, the capacitor (C) and the low-consumption inductance ballast (L) will limit the current to the specified value. After the AC current is commutated by the rectifying element (D), the AC current is converted into a DC current, which is supplied to the LED lamp to ignite the LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com