Full-automatic electric cooker

An electric rice cooker, a fully automatic technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of sticking meals, complicated operation, incomplete opening of the inner pot, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

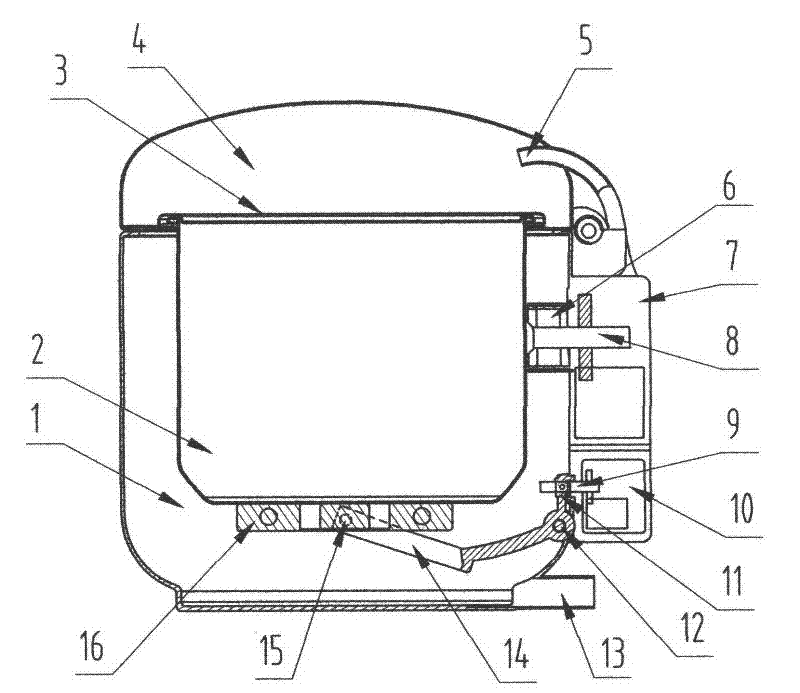

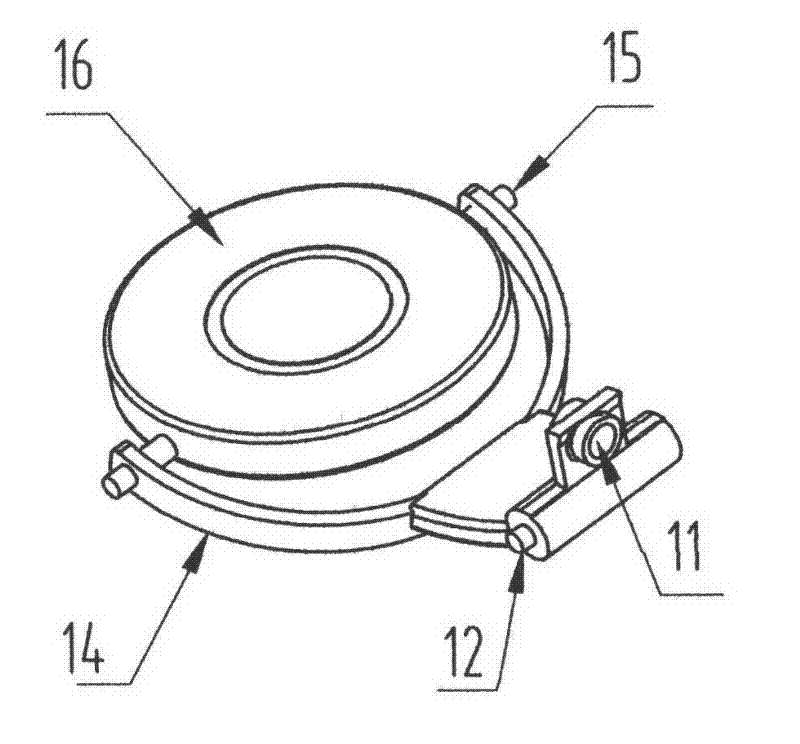

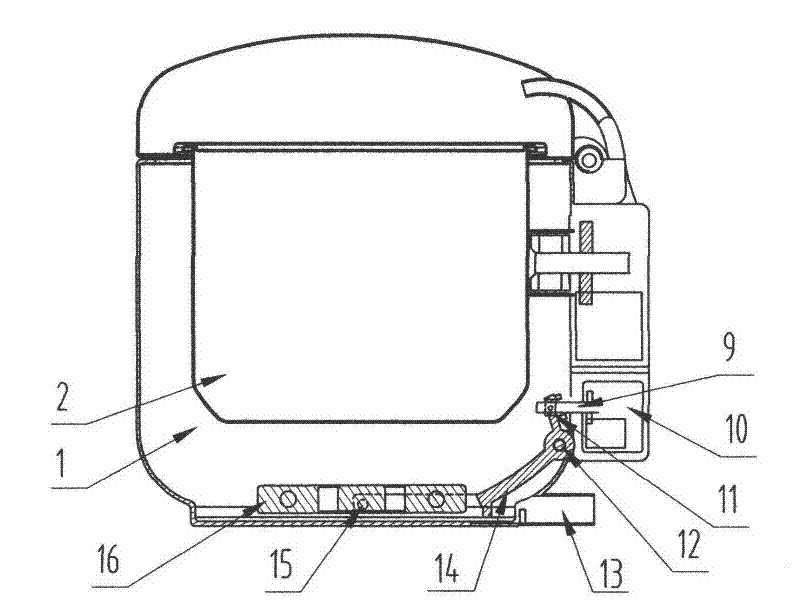

[0030] The present invention has: a pot shell 1 with an opening for supporting devices such as a dumping device, a lifting device, and a sealing function. The pot cover 4 opens and closes the opening of the pot shell 1 . The rice cooker 2 is a single metal container, which is used for pre-storing food materials, washing rice, cooking rice and cooking food. The rice-blocking cover 3 is used to block the rice grains and the rice-washing water can be discharged when washing rice and dumping the rice-washing water. The water adding device is composed of a water inlet solenoid valve, a flow sensor (the solenoid valve and the flow sensor are installed in the idle space in the body of the pot, not shown in the figure), a hose and a water spray nozzle 5, which are used for washing rice or cooking food. Clear water. The electric hot plate sensor assembly 16 is used for heating the rice cooker 2 and sensing the temperature of the rice cooker 2 when cooking food. Power machine 7, is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com