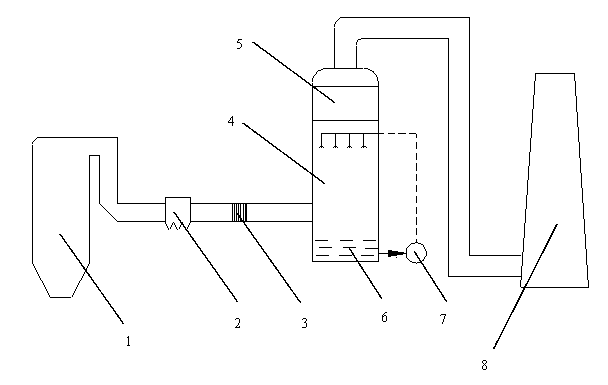

Method and system for simultaneously removing sulfur, niter and mercury from smoke based on catalytic oxidation

A technology of desulfurization, denitrification, mercury removal, and catalytic oxidation, which is applied in the field of air pollution control, can solve the problems of high energy consumption, large consumption, and economical impact, and achieve the effects of reducing operating costs, avoiding preparation, and improving economical efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Mn-Ce / TiO 2 Catalytic oxidation combined with calcium carbonate absorption for simultaneous desulfurization, denitrification and mercury removal

[0049] The catalyst loaded in the catalytic reactor is Mn-Ce / TiO prepared by precipitation deposition method 2 Catalyst, wherein the molar ratio of Mn / Ti is 0.3, and the molar ratio of Ce / Ti is 0.05. After the flue gas to be treated is dedusted by the dust collector, SO 2 Concentration is 450 ppm, NO concentration is 200 ppm, O 2 Content is 4.5%, Hg 0 The concentration is 0.10 mg / Nm 3 , the concentration of HCl is 20 ppm, the reaction temperature is 130°C, and the reaction space velocity is about 20000 h -1 . When the flue gas passes through the catalyst bed of the catalytic reactor, NO and Hg 0 with O 2 The speed of the catalytic oxidation reaction between NO and Hg 0 are oxidized to NO 2 and Hg 2+ Among them, the oxidation efficiency of nitrogen oxides reaches over 70%, the oxidation efficiency o...

Embodiment 2

[0050] Example 2: Pt / TiO 2 Catalytic Oxidation Combined with Calcium Hydroxide Absorption Simultaneous Desulfurization, Denitrification and Demercury

[0051] The catalyst loaded in the catalytic reactor is Pt / TiO prepared by impregnation method 2 Catalyst, wherein the Pt / Ti molar ratio is 0.05. After the flue gas to be treated is dedusted by the dust collector, SO 2 Concentration is 600 ppm, NO concentration is 250 ppm, O 2 Content is 4%, Hg 0 The concentration is 0.08 mg / Nm 3 , the HCl concentration is 10 ppm, the reaction temperature is 150°C, and the space velocity is about 15000 h -1 . When the flue gas passes through the catalyst bed of the catalytic reactor, NO and Hg 0 with O 2 The speed of the catalytic oxidation reaction between NO and Hg 0 are oxidized to NO 2 and Hg 2+ Among them, the oxidation efficiency of nitrogen oxides is about 75%, the oxidation efficiency of mercury is 90%, and the oxidation rate of sulfur dioxide is less than 1%. After that, ...

Embodiment 3

[0052] Embodiment 3: Mn-W / TiO 2 Catalytic oxidation combined with calcium carbonate absorption for simultaneous desulfurization, denitrification and mercury removal

[0053] The catalyst loaded in the catalytic reactor is prepared by hydrothermal method Mn-W / TiO 2 A catalyst wherein the Mn / Ti molar ratio is 0.2 and the W / Ti molar ratio is 0.02. After the flue gas to be treated is dedusted by the dust collector, SO 2 Concentration is 550 ppm, NO concentration is 180 ppm, O 2 Content is 5.5%, Hg 0 The concentration is 0.08 mg / Nm 3 , the concentration of HCl is 20 ppm, the reaction temperature is 140°C, and the space velocity is about 10000 h -1 . When the flue gas passes through the catalyst bed of the catalytic reactor, NO and Hg 0 with O 2 The speed of the catalytic oxidation reaction between NO and Hg 0 are oxidized to NO 2 and Hg 2+ Among them, the oxidation efficiency of nitrogen oxides reaches more than 80%, the oxidation efficiency of mercury reaches 98%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com