Automatic spraying device of large-size barrel

A technology of automatic spraying and large cylinder, applied in the direction of liquid spraying device, spraying device, etc. It can solve the problems of four corners and uneven spraying in spraying, and achieve the effect of improving quality and work efficiency, reducing production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

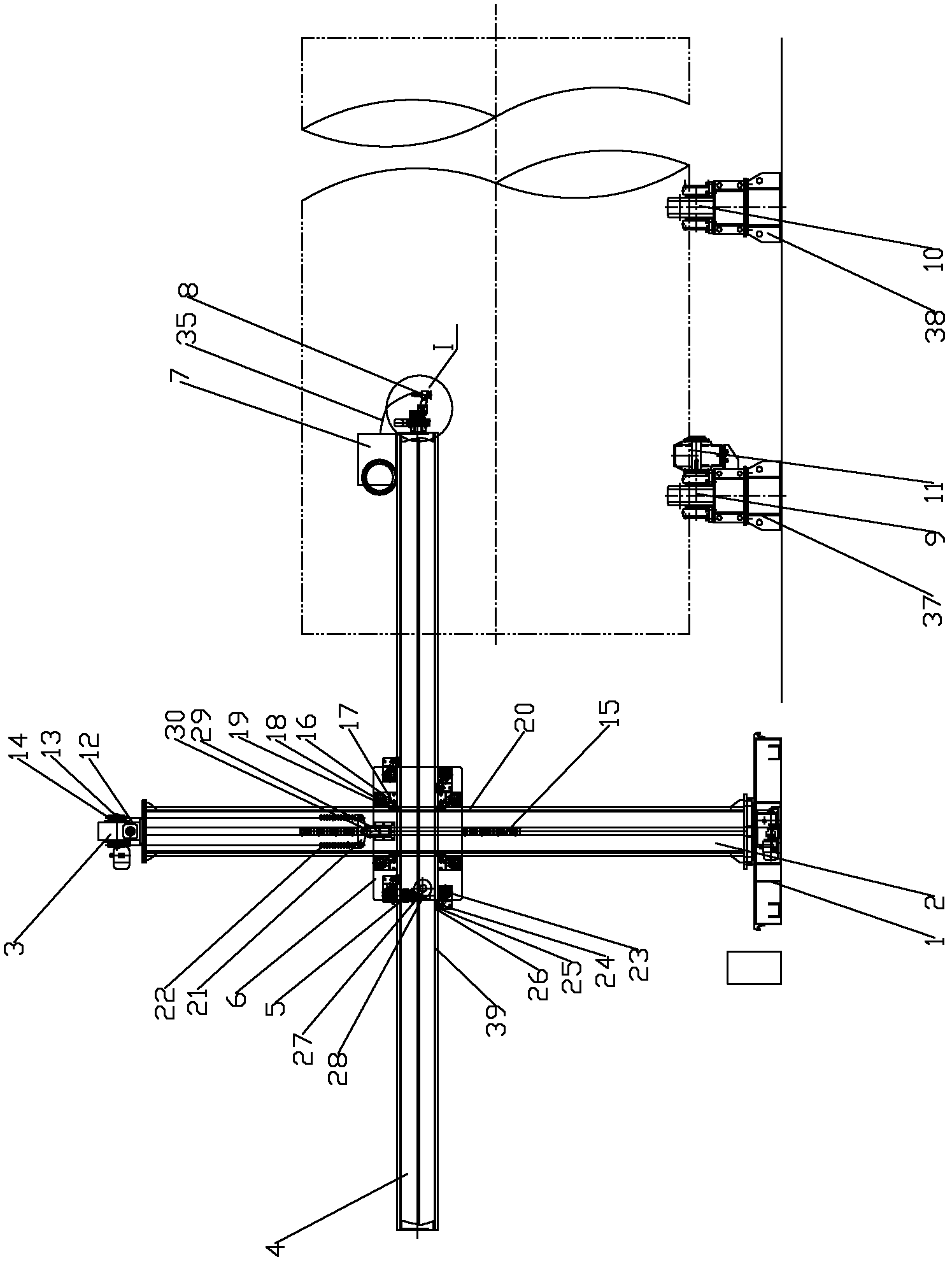

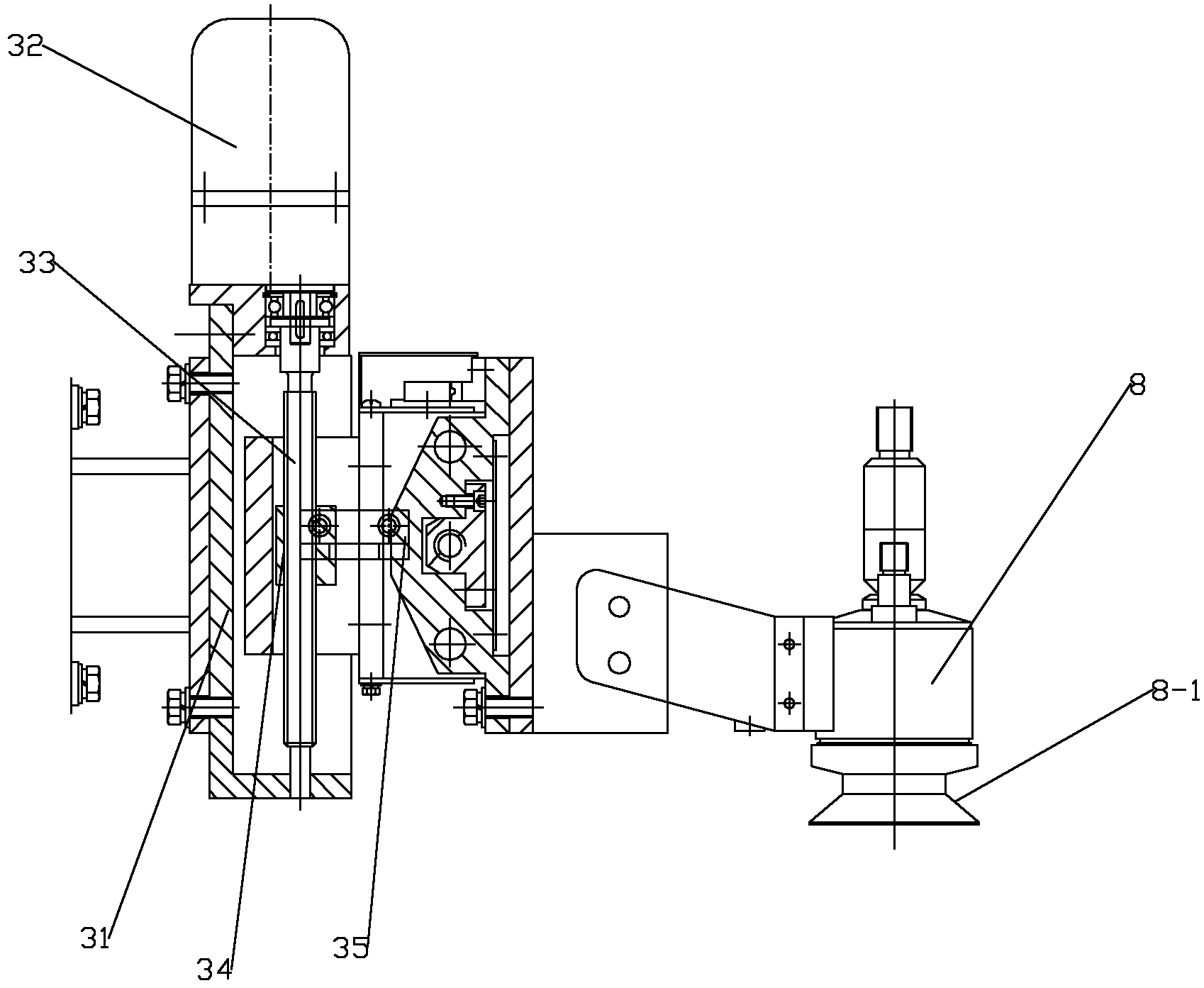

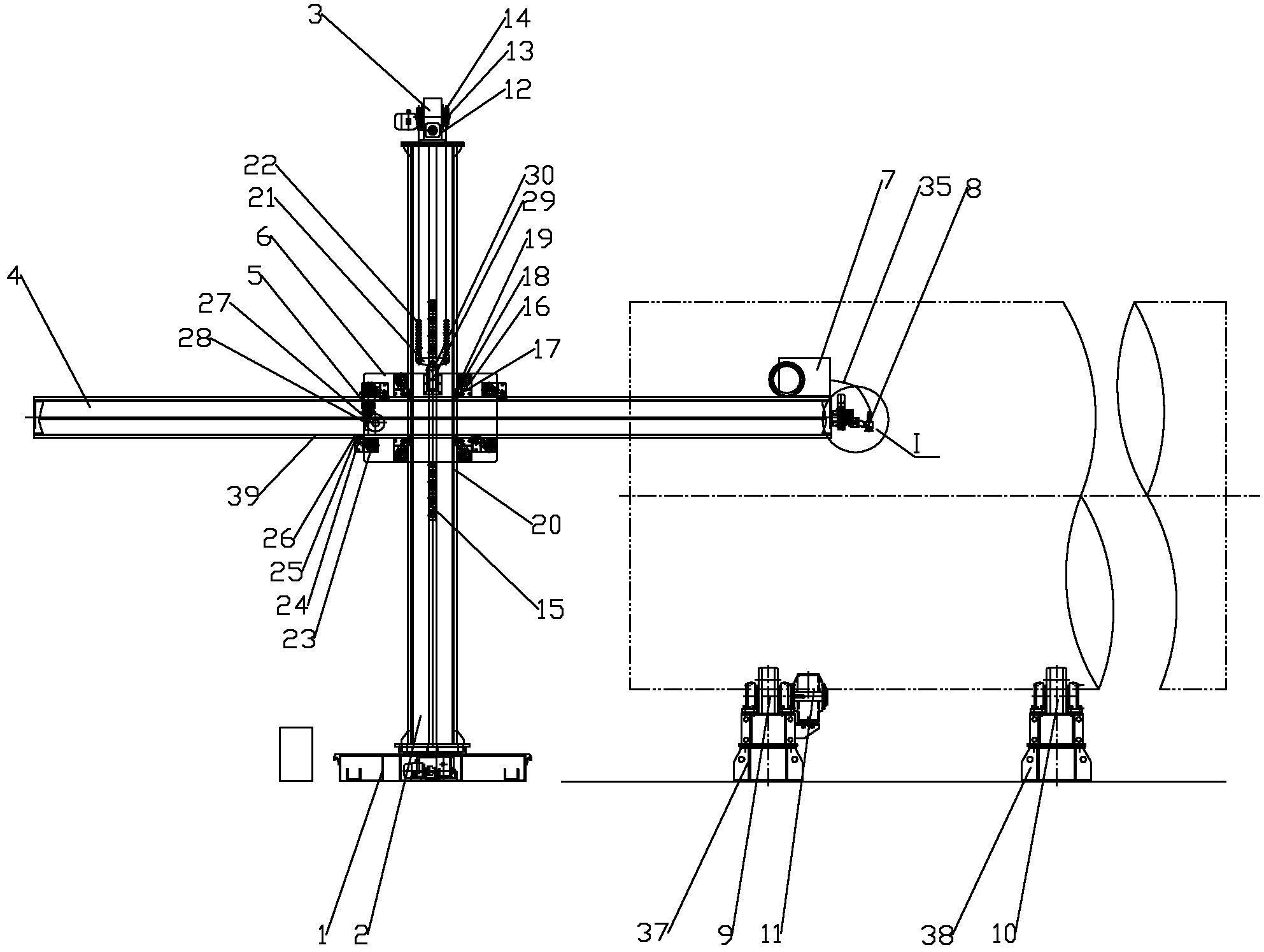

[0022] The present invention mainly includes fixed base 1, double column 2, lifting reduction motor 3, cross arm 4, cross arm reduction motor 5, guide seat 6, spraying wire feeding box 7, spray gun 8, driving roller 9, driven roller 10 and driving The roller motor 11, the double column 2 is fixed in the middle of the fixed base 1, the top of the double column 2 is provided with a sprocket bracket 12, and a sprocket shaft 13 is movably connected to the sprocket bracket 12; the two ends of the sprocket shaft 13 are respectively connected A chain wheel 14 is received, and the left end of the sprocket shaft 13 is axially connected to the lifting reduction motor 3; the double column 2 is provided with an anti-fall rack 15 from top to bottom.

[0023] The four corners of the upper and lower end surfaces of the guide seat 6 are respectively provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com