Forming and conveying device for thermoplastic composite material

A composite material and conveying device technology, which is applied in the direction of feeding device, forming tool, positioning device, etc., can solve the problem of lack of molding and manufacturing process of thermoplastic composite material, achieve good application prospects, simplify the production process and conveying process, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

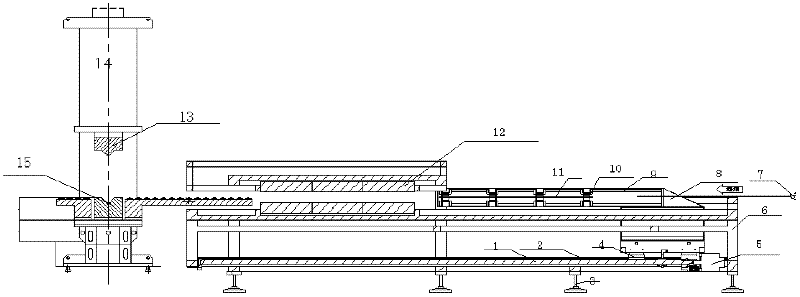

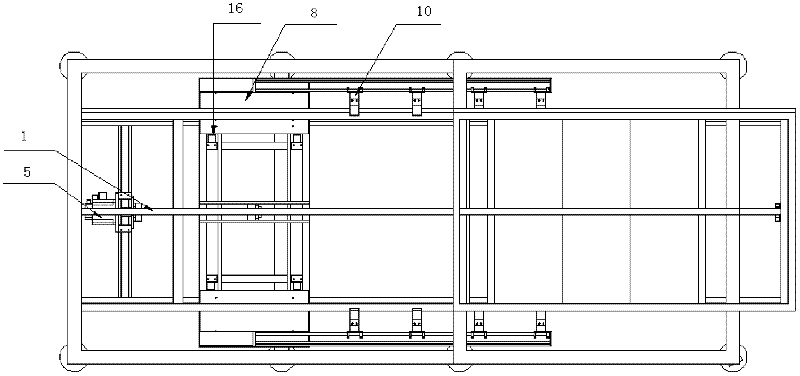

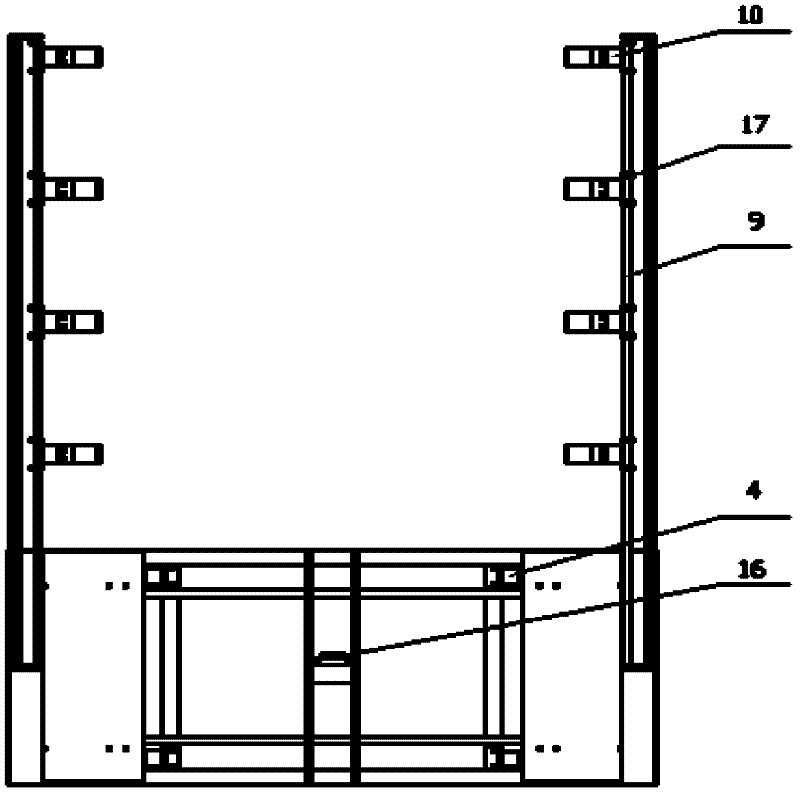

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

[0027] Figure 1 to Figure 4 The reference signs in are: 1 is the screw, 2 is the guide rail, 3 is the supporting caster, 4 is the screw nut, 5 is the servo motor, 6 is the bracket, 7 is the feeding port, 8 is the conveying part of the chassis, 9 is the chassis rod, 10 is the clamp, 11 is the thermoplastic composite material, 12 is the infrared radiation heater, 13 is the upper mold, 14 is the hydraulic press, 15 is the lower mold, 16 is the first cylinder, 17 is the locking bolt, 18 is The second air cylinder, 19 is an upper clamping portion, and 19′ is a lower clamping portion.

[0028] In this example, if figure 1 As shown, the molding conveying line of the thermoplastic composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com