Grid mould release agent

A release agent and grid technology, which is applied in coating, casting molding equipment, casting molds, etc., can solve the problems of unstable product quality, low production efficiency, poor molding of release agent, etc., and achieve smooth exhaust and prolong Long service life, easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

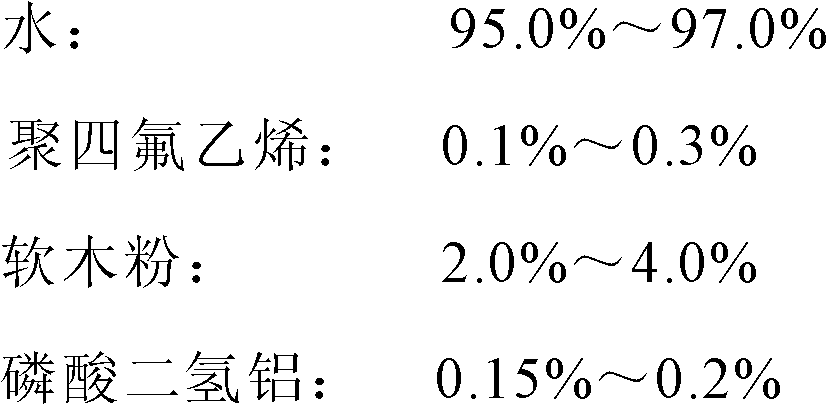

Method used

Image

Examples

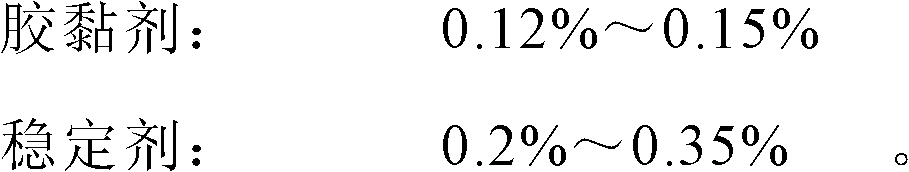

Embodiment 1

[0029] Embodiment 1: A grid release agent, the mass percentage of each component is as follows: water 95.0%, polytetrafluoroethylene: 0.3%, cork powder 4.0%, aluminum dihydrogen phosphate 0.2%, adhesive 0.15%, stable 0.35% agent, mixed and prepared according to the above ratio to form an emulsion, heated, stirred, and cooled to form a release agent. It has the advantages of easy spraying, good adhesion, high temperature resistance, small surface tension, high pressure resistance, and smooth exhaust. It is very suitable for The high-temperature gravity-cast lead-calcium alloy grid can effectively reduce the pores and cracks of the grid, and at the same time reduce the number of injection molds per unit time, improve production efficiency and improve product quality.

Embodiment 2

[0030] Embodiment 2: A grid release agent, the mass percentage of each component is as follows: water 97.0%, polytetrafluoroethylene: 0.1%, cork powder 2.4%, aluminum dihydrogen phosphate 0.18%, adhesive 0.12%, stable 0.2% agent, according to the above ratio, mixed and prepared into an emulsion, heated, stirred, and cooled to form a release agent, which has the advantages of easy spraying, good adhesion, high temperature resistance, small surface tension, high pressure resistance, and smooth exhaust, etc., very suitable for The high-temperature gravity-cast lead-calcium alloy grid can effectively reduce the pores and cracks of the grid, and at the same time reduce the number of injection molds per unit time, improve production efficiency and improve product quality.

Embodiment 3

[0031] Embodiment 3: A grid release agent, the mass percentage of each component is as follows: water 96.0%, polytetrafluoroethylene: 0.2%, cork powder 3.2%, aluminum dihydrogen phosphate 0.17%, adhesive 0.13%, stable 0.3% agent, according to the above ratio, mixed and prepared into an emulsion, heated, stirred, and cooled to form a release agent, which has the advantages of easy spraying, good adhesion, high temperature resistance, small surface tension, high pressure resistance, and smooth exhaust, and is very suitable for The high-temperature gravity-cast lead-calcium alloy grid can effectively reduce the pores and cracks of the grid, and at the same time reduce the number of injection molds per unit time, improve production efficiency and improve product quality.

[0032] The production process of the above-mentioned release agent: heat water to boiling, add bone glue and polyvinyl alcohol to melt completely, add aluminum dihydrogen phosphate and cork powder and boil for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com