Laser detection method and device for vibration of continuous casting mold

A continuous casting mold, laser detection technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of easy wear and tear of contact probes, short service life, affecting workers' operation, etc., and achieve measurement accuracy. Easy to guarantee, enhance portability, easy to grasp the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

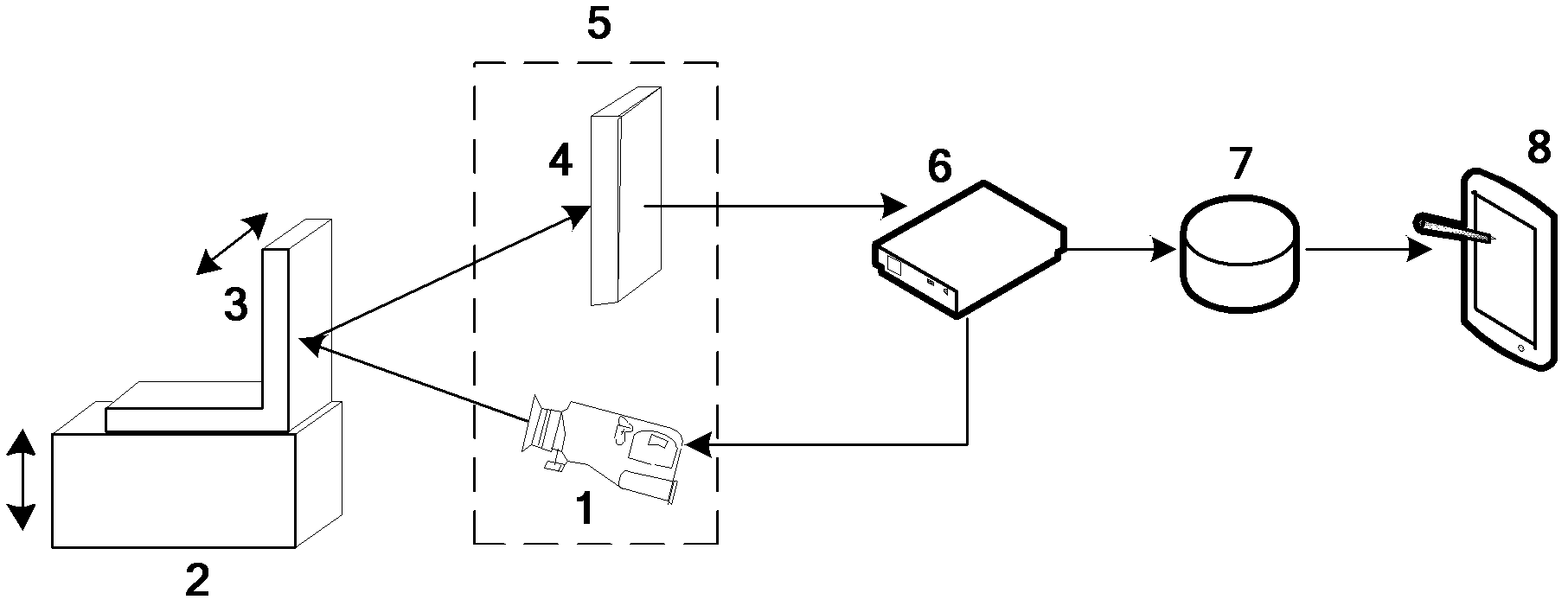

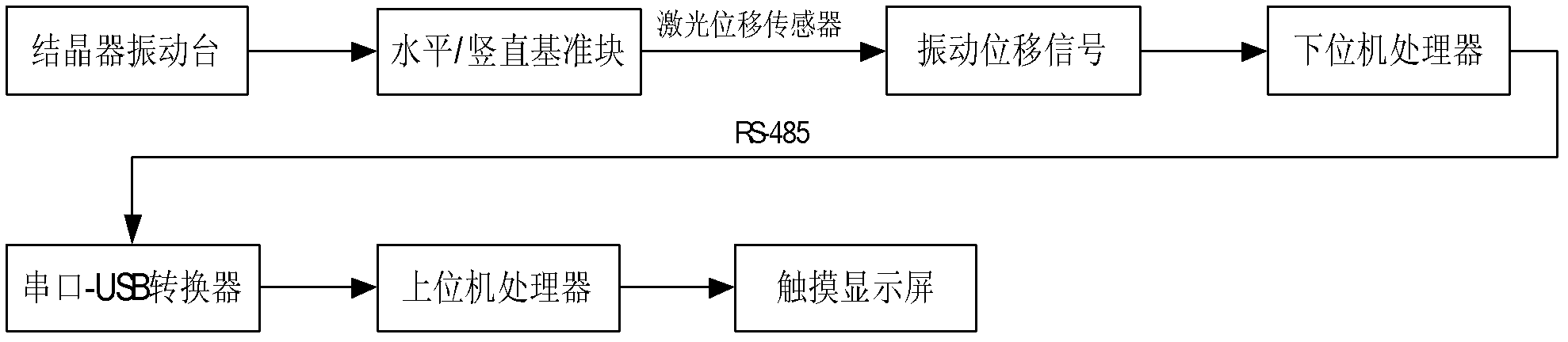

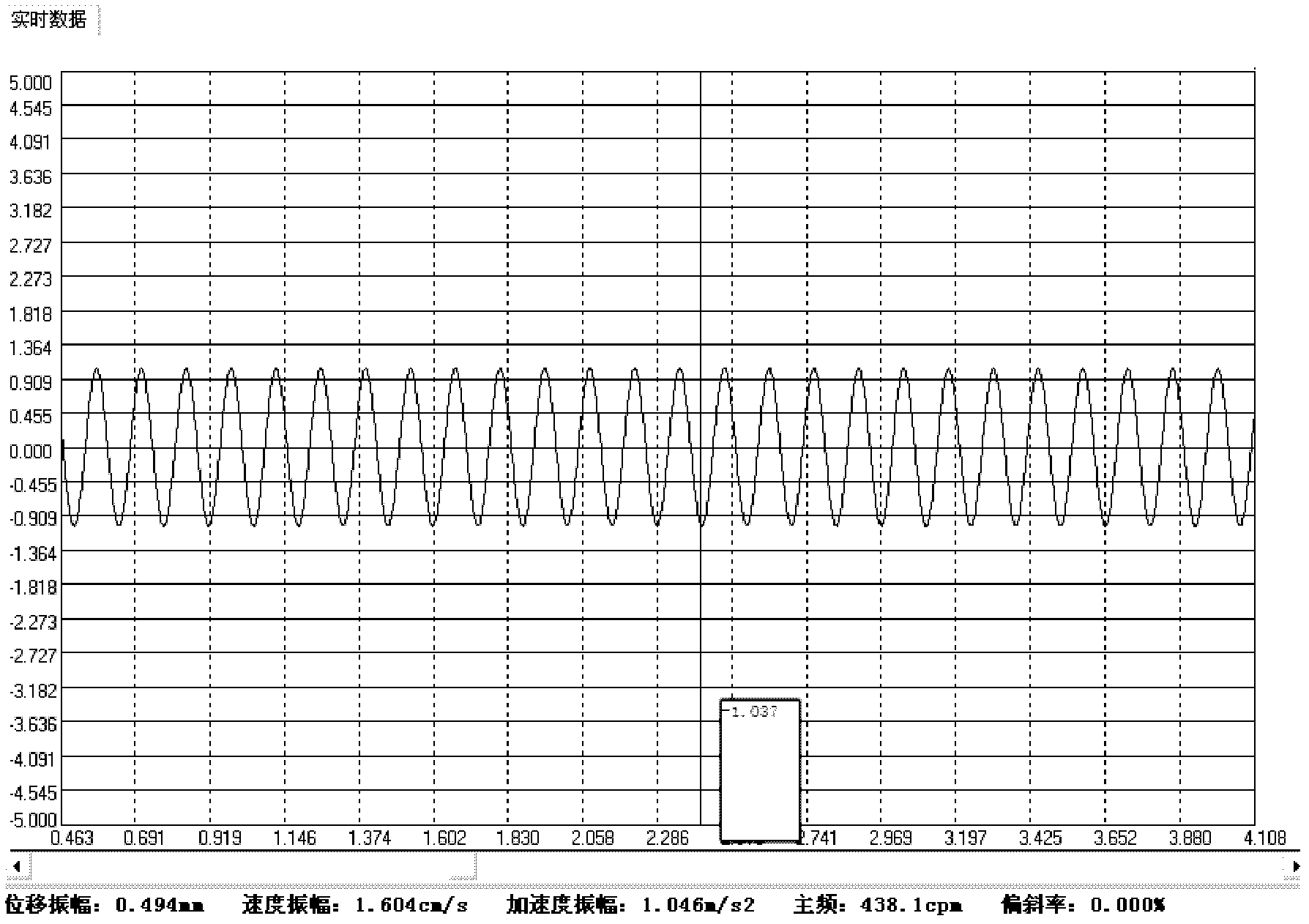

[0034] When inspecting the crystallizer on-site, first install the horizontal / vertical reference module 3 on the crystallizer platform 2, and adjust it to a suitable position, align the laser head 1 of the laser displacement sensor 5 with the horizontal / vertical reference block 3 The distance between the laser head 1 of the laser displacement sensor 5 and the horizontal or vertical surface of the horizontal / vertical reference block is within the range measurement range through the adjustment of the universal support. The analog signal output by the laser displacement sensor 5 is filtered and processed by the signal processor 7 of the lower computer, and then conditioned by the conditioning circuit to output an appropriate acquisition voltage signal. The voltage signal is obtained as a digital signal by the A / D conversion controller, and then the signal is preprocessed by the signal processor 7 of the lower computer, and the preprocessed signal is transmitted to the serial port-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com