Method for preventing narrow surface of continuous casting sheet billet from bulging

A slab and narrow face technology, which is applied in the field of continuous casting slab bulging, can solve problems such as slab shell narrow face bulging, slab shell thickness is not enough, slab narrow face bulging, etc., to achieve the elimination of slab Belly bulging, elimination of bulging on the narrow side, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

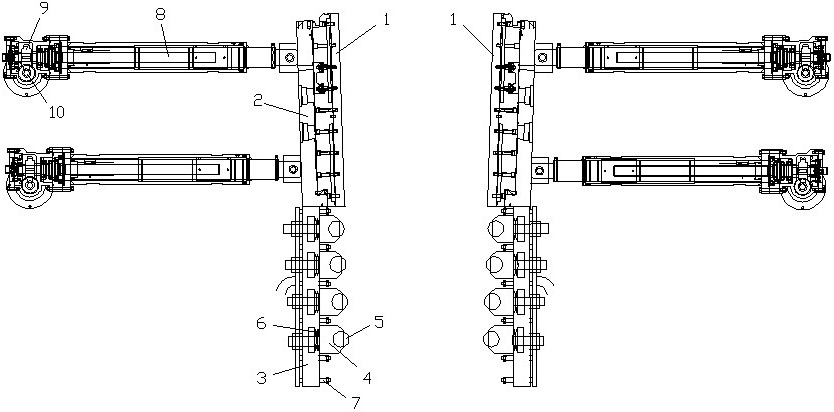

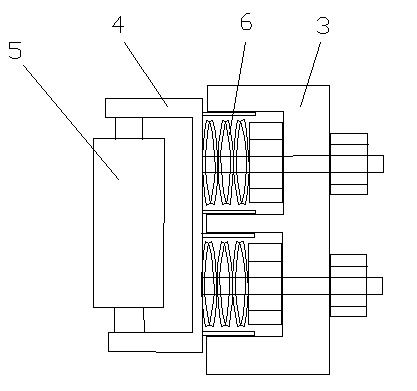

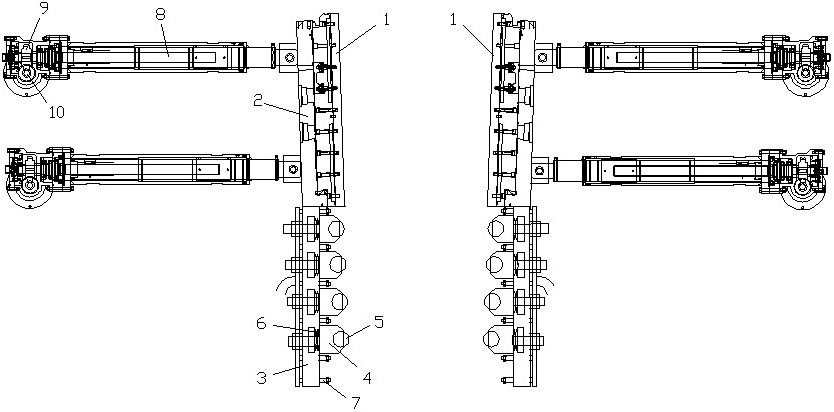

[0025] figure 1 Schematic diagram of the structure of the narrow-face copper plate and the foot roll device of the method for preventing continuous casting slab narrow-face bulging of the present invention; figure 2 It is a top view of the foot roller device.

[0026] As shown in the figure, the method for preventing the narrow face of the continuous casting slab from bulging in this embodiment includes measure a: Calculate the amount of drawing of the copper plate on the narrow face of the crystallizer by the following formula,

[0027] Drawing heat of narrow copper plate = flow rate of cooling water for narrow copper plate × specific heat capacity of water × temperature difference between inlet and outlet of cooling water for narrow copper plate,

[0028] Among them, the temperature difference between the inlet and outlet of the narrow copper plate cooling water = (the outlet temperature of the narrow copper plate cooling water during normal casting - the outlet water temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com