Combined crimping device of corrugated case print fluting machine

A corrugated box and combined line pressing technology is applied in the field of the line pressing device of the corrugated box printing and slotting machine, which can solve the problems of inaccurate positioning of corrugated cardboard, high waste rate of carton boxes, and reduce production costs, labor intensity, The effect of improving the quality of cartons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

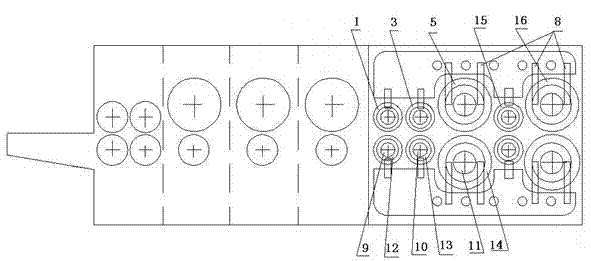

[0024] Embodiment 1: Set up preliminary pre-pressing wheel axle 9, medium crimping wheel axle 10, main crimping forming wheel axle 11 and each pair above and below, and arrange in parallel with slotting shaft; Preliminary pre-pressing wheel seat 12, moderate crimping wheel seat 13 and the main pressure line forming wheel seat 14 are slidably mounted on the corresponding upper and lower wheel shafts, and a shift fork groove 7 is set on each wheel seat, and a shift fork 8 is slid in each group of shift fork grooves, and is fixedly installed on the adjustment sliding mechanism plate Make sure that the centerlines of each set of crimping wheels are aligned; each crimping wheel is fixed on the corresponding wheel base with bolts.

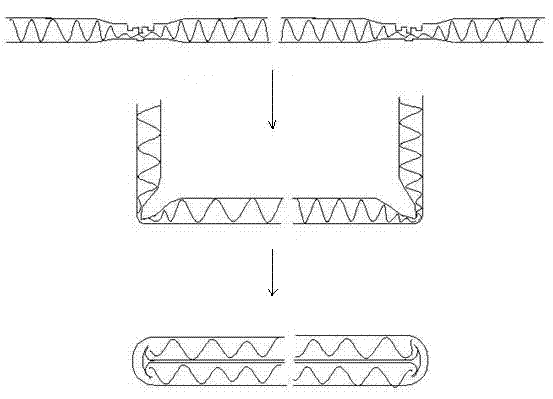

[0025] Preliminary preloading wheel set: flat structure, the upper wheel for preliminary preloading is a flat wheel made of steel coated with polyurethane rubber, the hardness is 65-70 degrees, the width of the pressure surface is 30mm, and the chamfer on...

Embodiment 2

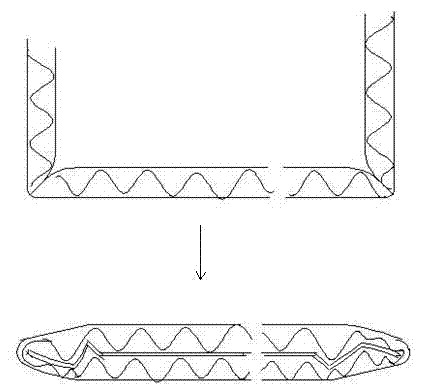

[0028] Embodiment 2: The setting of the preliminary pre-pressing wheel set is the same as that of Example 1. The crimping forming wheel set omits a set of moderate crimping wheels with a flat-to-concave structure, and only includes the main crimping with a concave-to-three-convex structure. The upper wheel 5 and the crimping forming lower wheel 6a, the setting of the main crimping forming upper wheel 5 is the same as that of Embodiment 1, the crimping forming lower wheel 6a has a pressure surface width of 25 mm, and a center line with a width of 2 mm and a height of 1 mm is set. Protrusions, two side protrusions with a height of 0.6mm and a width of 2mm are symmetrically arranged on both sides of the center line, and the inner edges of the two side protrusions are 3mm apart, and both sides of the wheel are chamfered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com