Method for modifying ink-jet printer into flat printer

A technology for inkjet printers and flatbed printers, which can be used in typewriters, printing, etc., to solve problems such as inability to print T-shirts and other fabrics, and inability to print rigid ceramic sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] How to convert an inkjet printer to a flatbed printer:

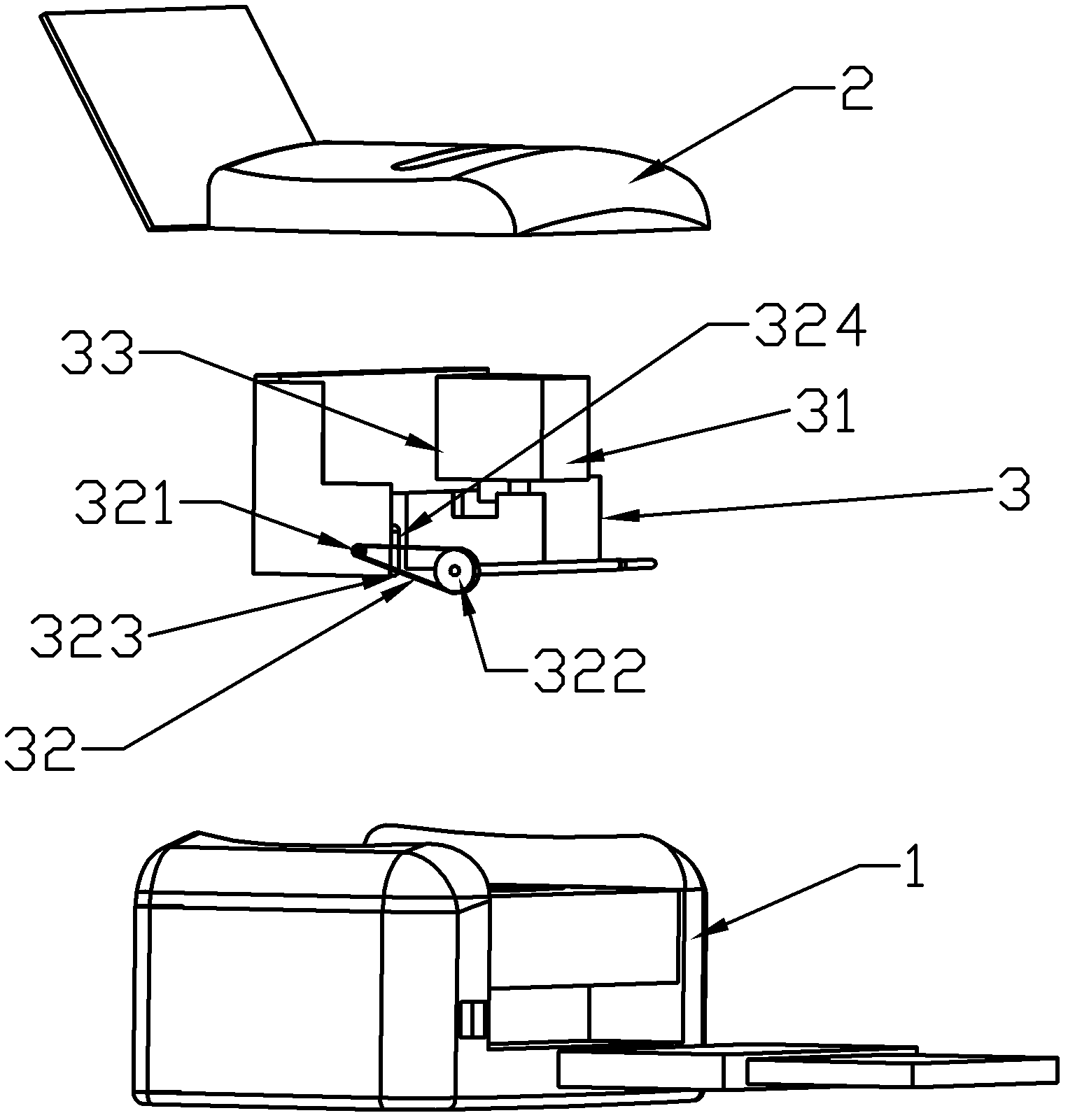

[0033] see Figure 4 After the ordinary inkjet printer is removed from the shell and the top cover, the core is taken out, and the printing inkjet system 31, the driving wheel 321, the driven wheel 322, the synchronous toothed belt 323 and the drive wheel 321 connected to the printing inkjet system 31 and the paper feeding drive system are reserved. Drive motor 324 and circuit control system 33 .

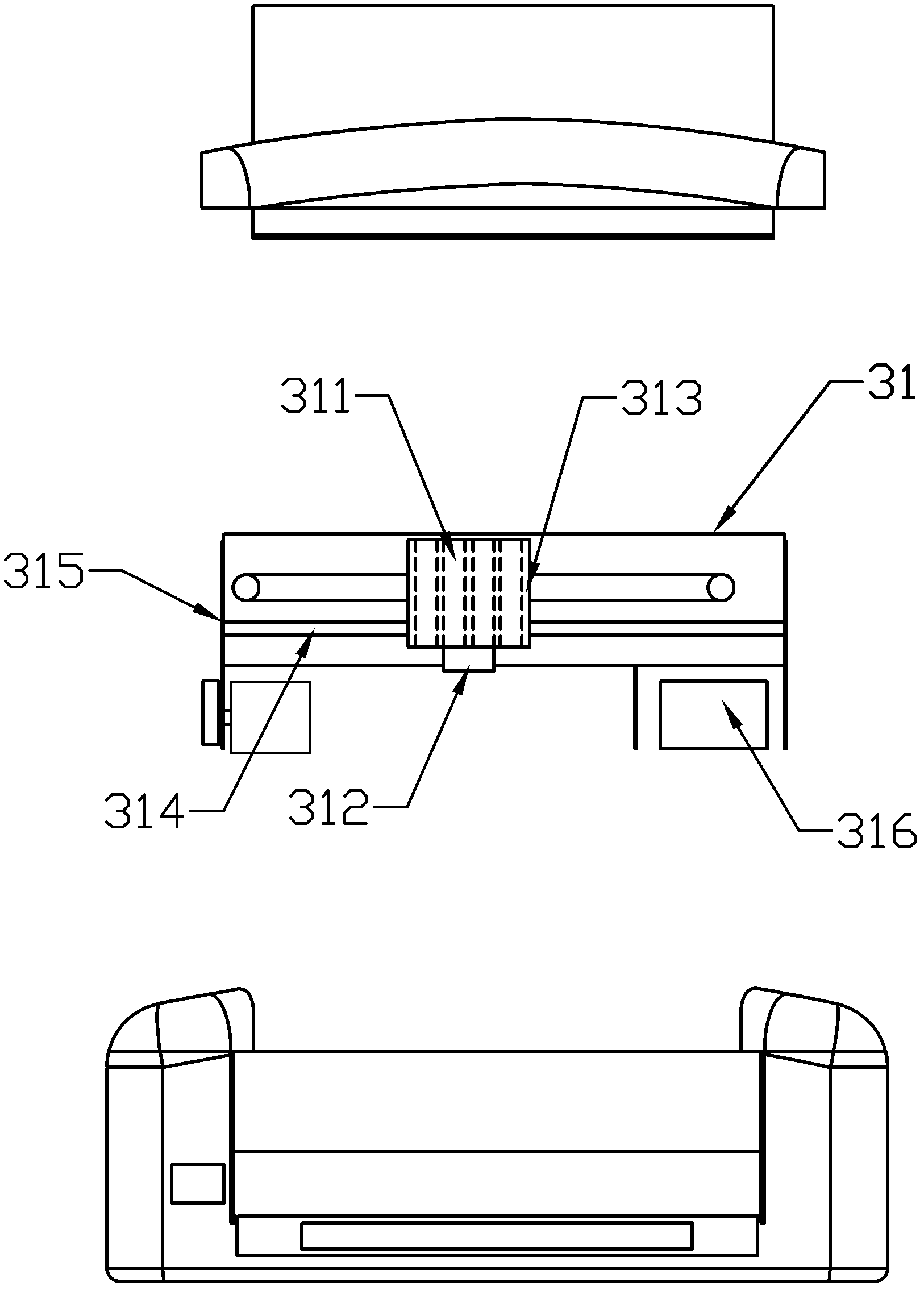

[0034] see Figure 5 , set up a base 6, two support frames 5 and a fixing device 4, and the printing inkjet system 31 is fixed on the base 6 by the fixing device 4; a guiding system that makes the printing medium move linearly is added, and the guiding system includes a linear guide rail 71 and can move along a straight line Guide rail 71 is made the guide plate 72 of reciprocating motion, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com