Skid-mounted fueling station for gas filling and charging

A charging station, skid-mounted technology, applied in the field of skid-mounted gas refueling-charging stations, can solve the problems of low utilization rate, large charging surge current of the grid, large capacity of substations and lines, etc., to achieve short station construction time and slow down the power grid The effect of pressure and big gains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

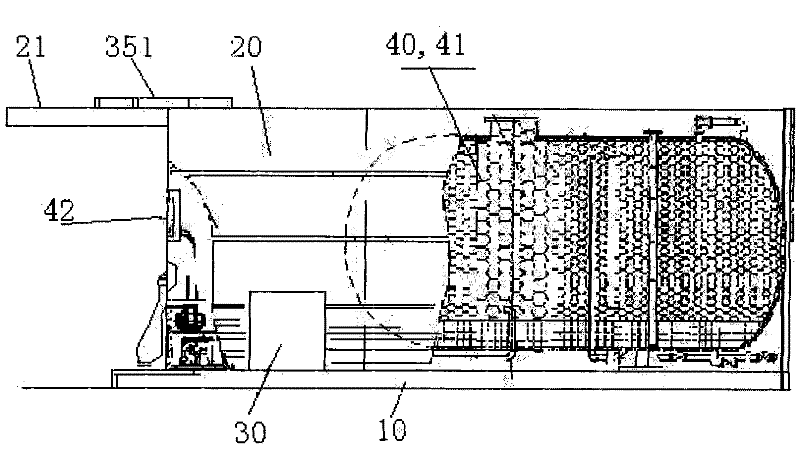

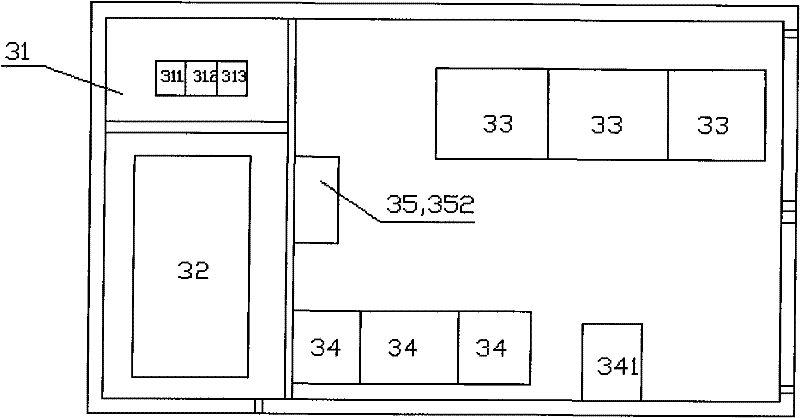

[0027] The following is attached figure 1 and 2 The concrete structure of the present invention is illustrated:

[0028]The skid-mounted gas filling-charging station of the present invention comprises a skid body 10, an outer cover 20 fixed on the skid body, a charging device 30 and an air filling device 40, the skid body is made of channel steel to form a rectangular frame, and the floor is laid on the frame; the outer cover 20 is provided with On the sled body 10, it is composed of front, rear, left and right walls; the charging device 30 is located in the outer cover 20, which includes an AC power grid access terminal 31, monitoring equipment 32, energy storage equipment 33 and charging equipment 34, The components in the charging device are connected to each other by wires. The gas filling device 40 includes a barrier explosion-proof gas storage tank 41 and a gas filling machine 42 .

[0029] Lifting rings are set on the frame for the overall hoisting of the charging st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com