Hydraulic synchronous jacking system

A hydraulic synchronous jacking and plug cylinder technology, applied in the direction of hoisting devices, hoisting devices, etc., can solve the problems of jacking control accuracy and control points increase, unable to meet multi-point synchronous jacking, uneven load distribution, etc., to achieve improved Automatically control precision, provide work efficiency and high detection precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

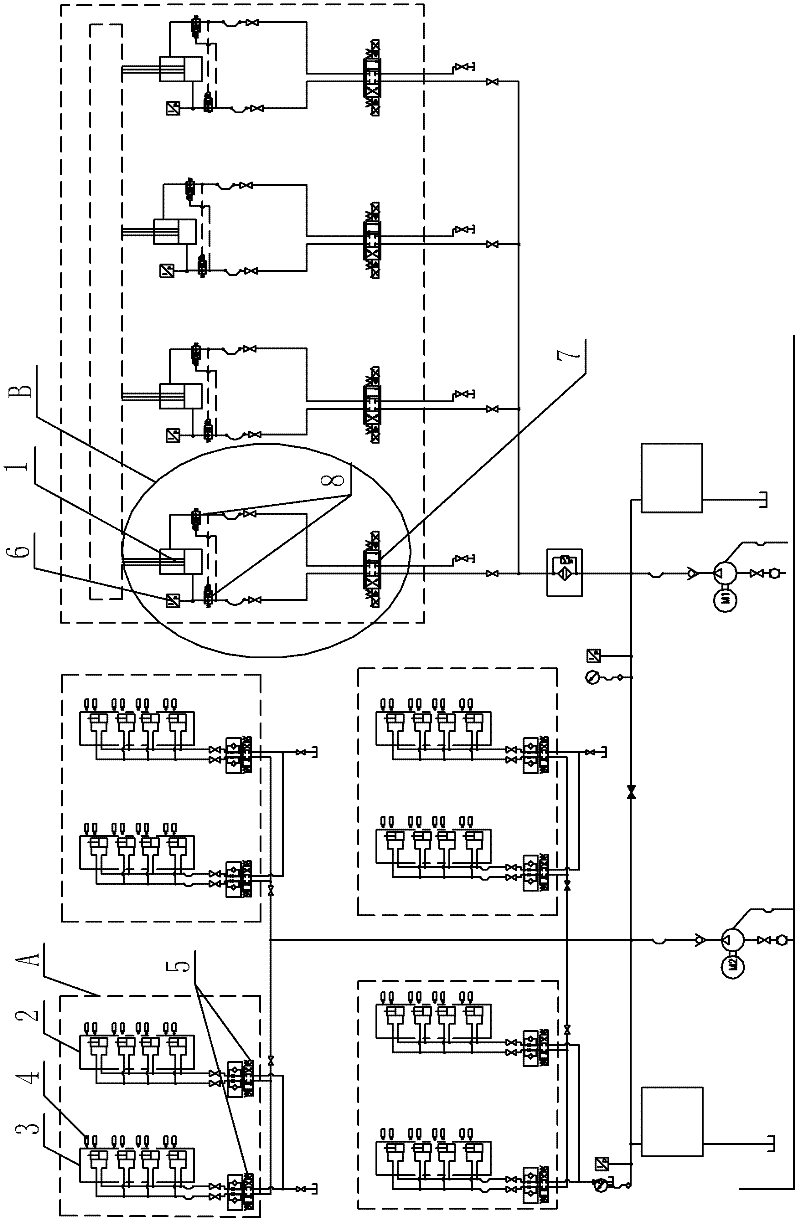

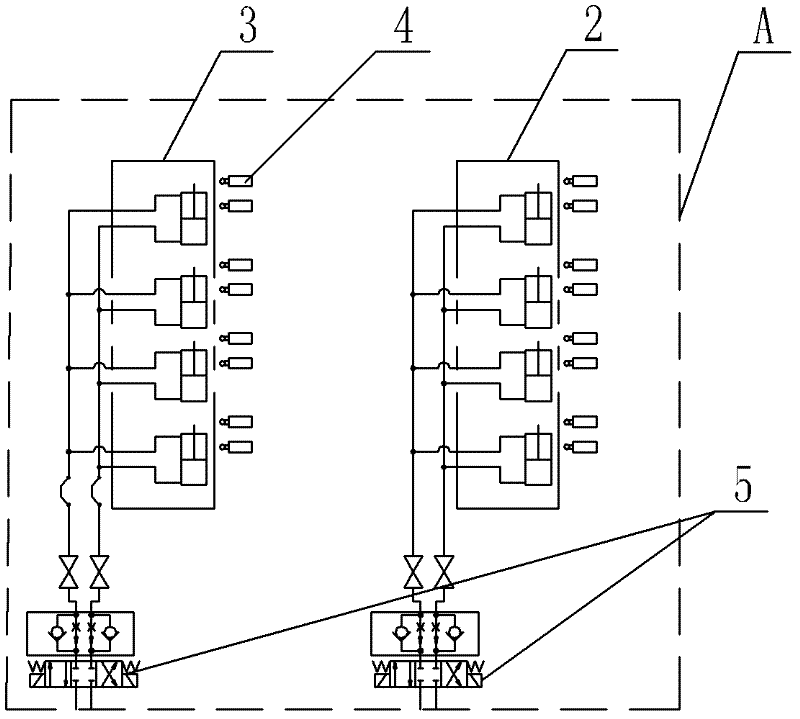

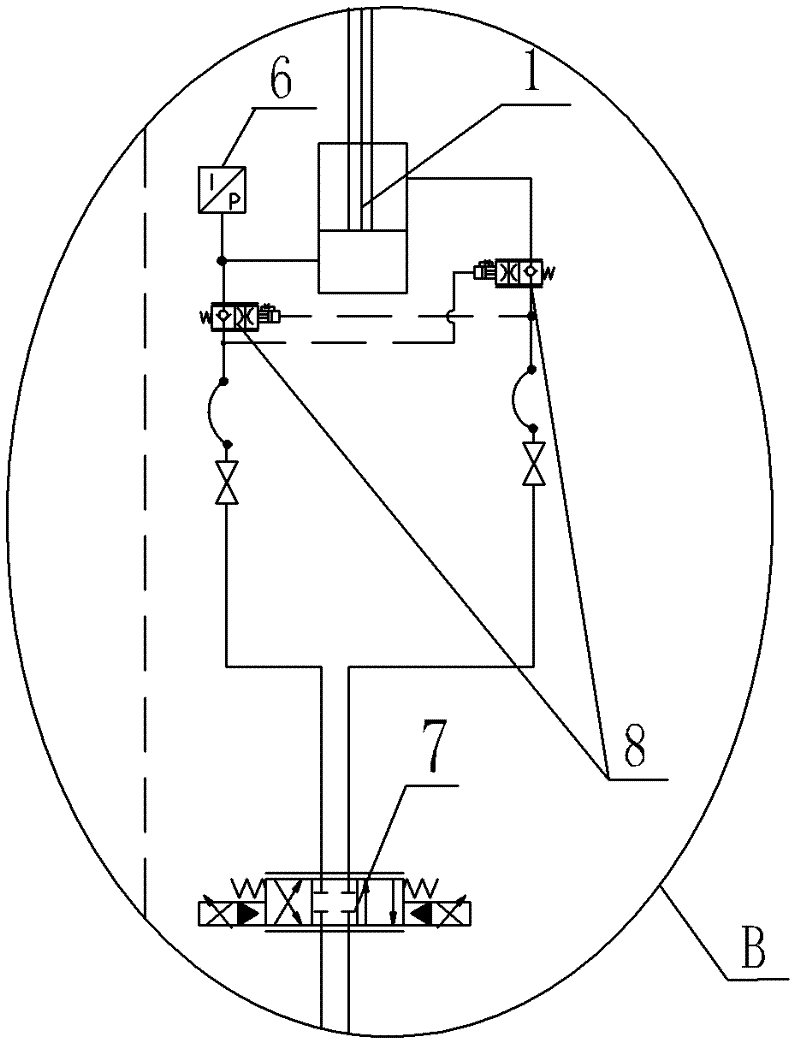

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] Such as figure 1 , figure 2 , image 3 As shown, the structural schematic diagram of the optimal embodiment of the hydraulic synchronous jacking system of the present invention. A hydraulic synchronous jacking system, with four main cylinders 1, console, programmable logic controller PLC with SSI interface module, switching power supply and eight electromagnetic reversing valves, each main cylinder 1 is equipped with a proportional Reversing valve, four upper pin oil cylinders 2, four lower pin oil cylinders 3 and a set of external opening device 4 with multi-turn absolute encoder; each electromagnetic reversing valve controls the same main oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com