Sulfide heavy metal chelating agent and preparation method thereof

A heavy metal collector and sulfide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of long synthesis route, low yield, low zinc removal rate, etc., and achieve convenient operation. , The effect of short settling time and not easy secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

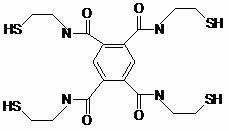

[0026] A kind of sulfide heavy metal collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromelliticamide, the preparation method of which is as follows:

[0027] At 20°C, in a 150mL three-neck flask, dissolve mercaptoethylamine hydrochloride to pyromellitic anhydride at a molar ratio of 4.4, that is, dissolve 5.0 g of mercaptoethylamine hydrochloride and 2.18 g of pyromellitic anhydride in 75 mL of dimethylformaldehyde In the amide, react under stirring for 4 hours to obtain the heavy metal chelating collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromellitic tetracarboxamide (TMBTC for short), the reaction yield is 22.43%.

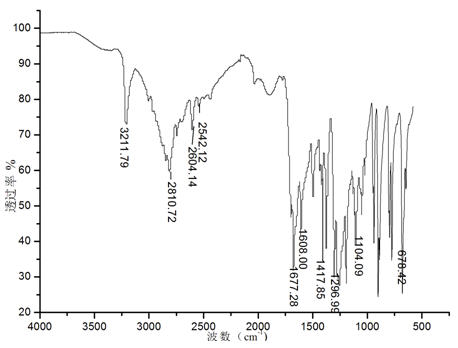

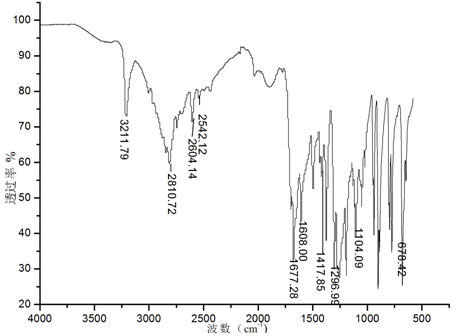

[0028] Infrared IR and nuclear magnetic NMR characterization results are as follows:

[0029] IR(KBr disk, cm -1 ): 3211.79 s(V N- H), 2542.12w( S-H ), 1677.28(V C=O), 1608 ss (δ in-plane bending N-H), 1417.85 m (V C=C), 1296.99ss (V C-N), 1296.99 m (V C-N), 1104.09 (V C-S), 678.42 {out-of-plane stretch C-H(Ar)}. ...

Embodiment 2

[0033] A kind of sulfide heavy metal collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromelliticamide, the preparation method of which is as follows:

[0034]At 5°C, in a 150mL three-neck flask, dissolve mercaptoethylamine hydrochloride to pyromellitic anhydride at a molar ratio of 4.8, namely 5.46 g of mercaptoethylamine hydrochloride and 2.18 g of pyromellitic anhydride in 75 mL of dimethylformaldehyde In the amide, react under stirring for 6 hours to obtain the heavy metal chelating collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromellitic tetracarboxamide (TMBTC for short), the reaction yield is 51.62%.

[0035]

Embodiment 3

[0037] A kind of sulfide heavy metal collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromelliticamide, the preparation method of which is as follows:

[0038] At -5°C, in a 150mL three-necked flask, dissolve mercaptoethylamine hydrochloride to pyromellitic anhydride at a molar ratio of 5.2, that is, 5.91 g of mercaptoethylamine hydrochloride and 2.18 g of pyromellitic anhydride are dissolved in 75 mL of dimethyl In formamide, react under stirring for 8 hours to obtain the heavy metal chelate collector N 1 ,N 2 ,N 4 ,N 5 -Tetrakis(2-mercaptoethyl) 1,2,4,5-pyromellitic tetracarboxamide (TMBTC for short), the reaction yield is 76.17%.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com