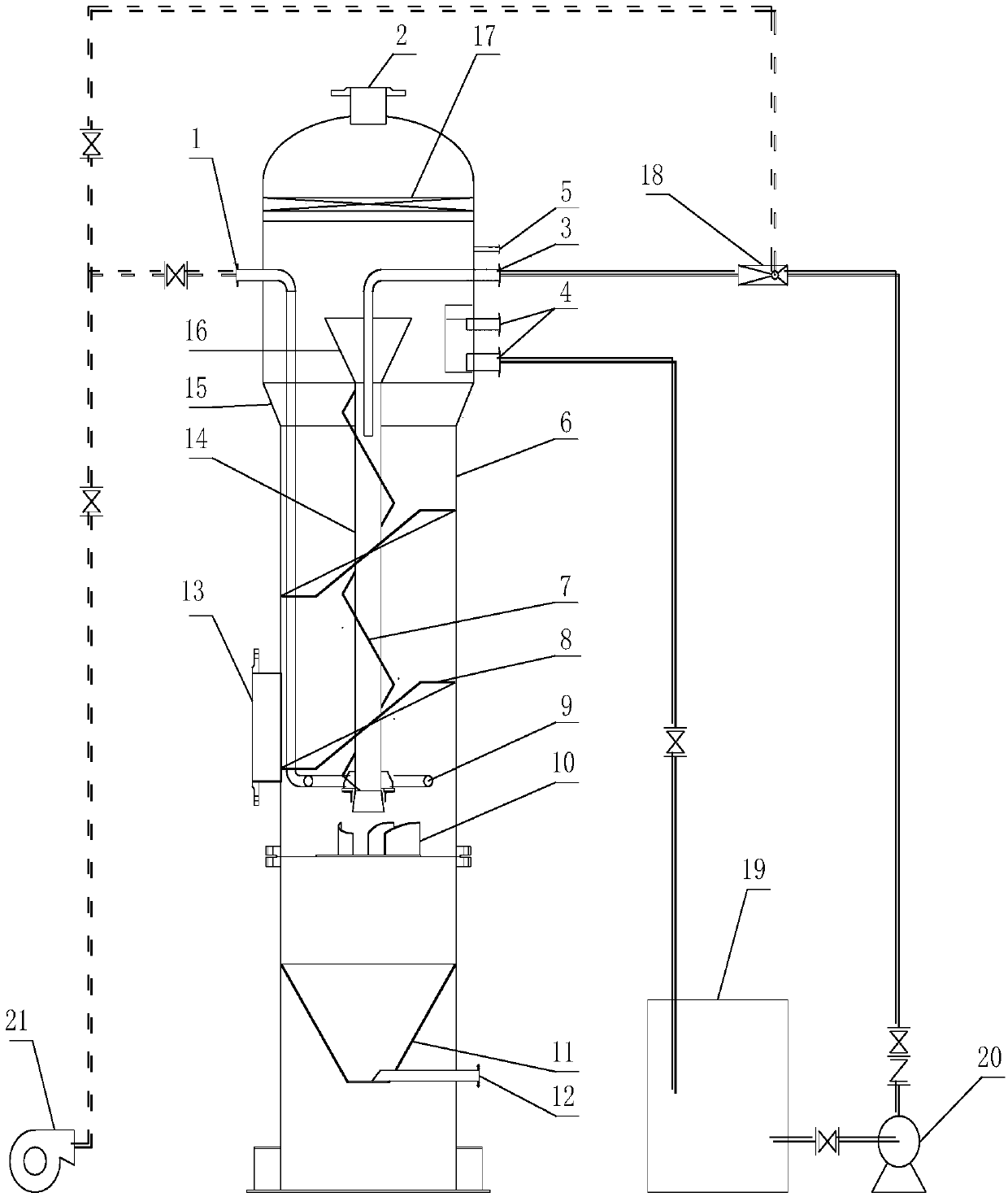

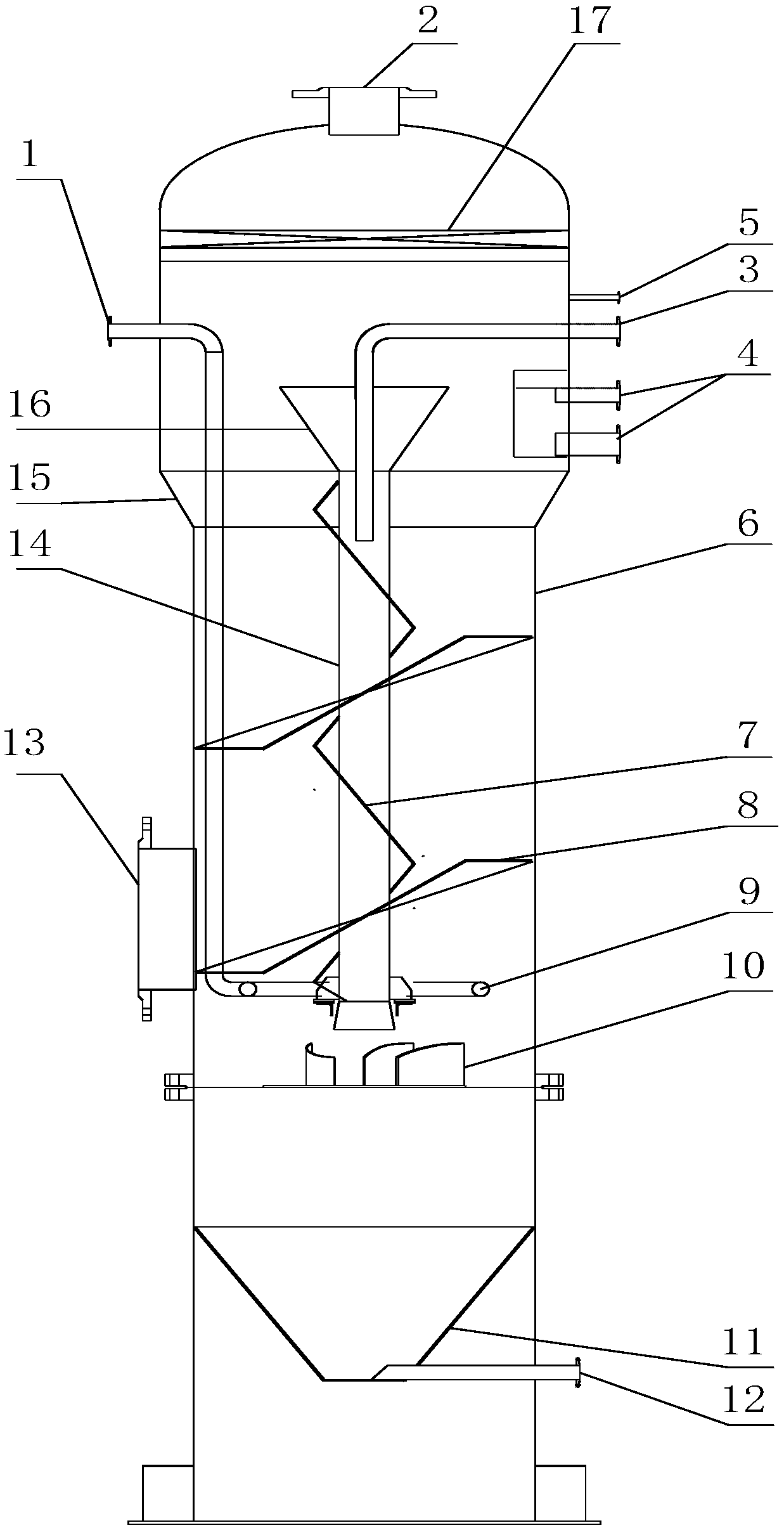

Cyclone bubble column three-phase reactor

A technology of swirl bubble tower and reactor, which is applied in the field of swirl bubble tower three-phase reactor, to achieve the effect of accelerating movement, ensuring separation effect and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

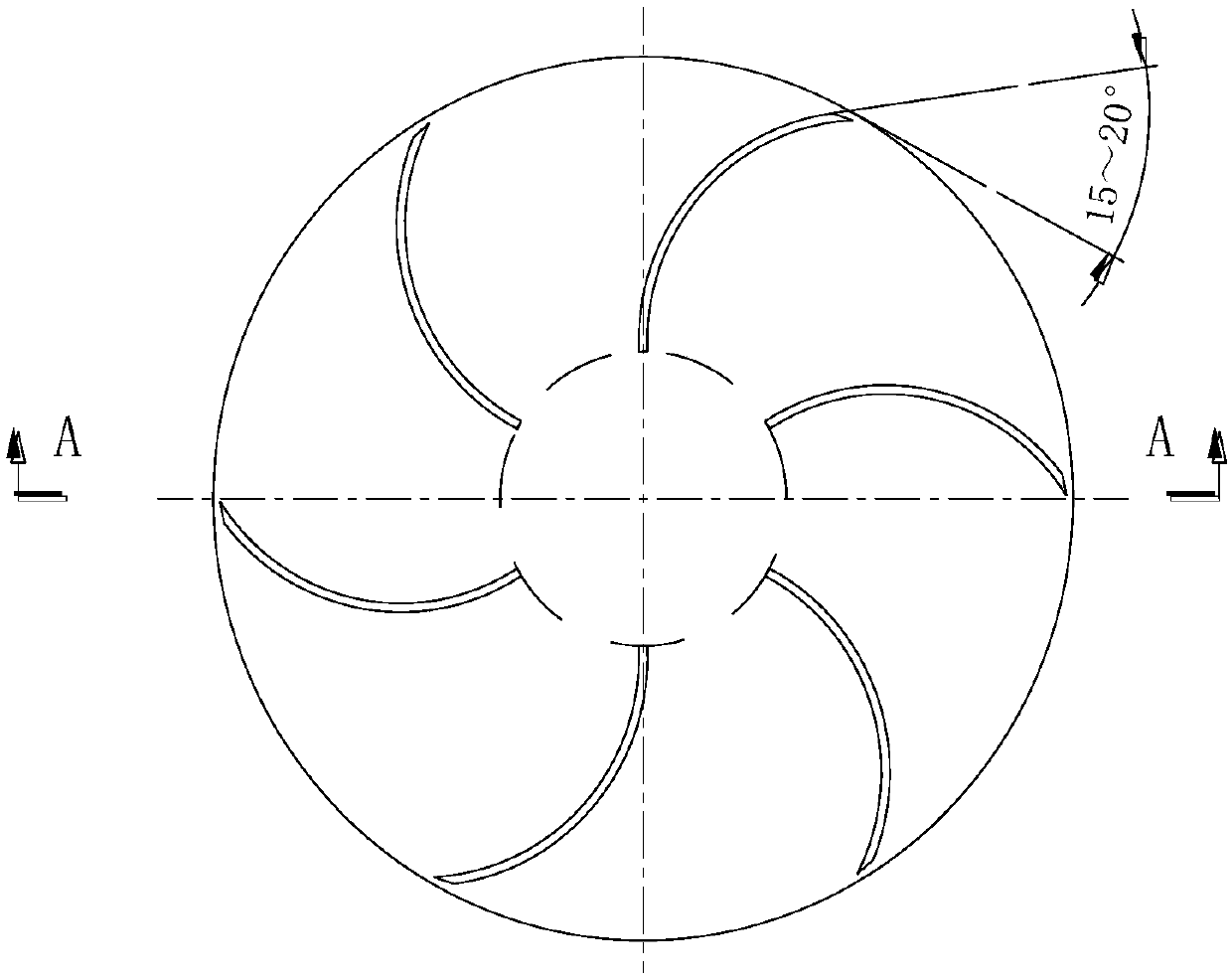

Method used

Image

Examples

Embodiment 1

[0046] Continuous water inlet is adopted, and the flow rate of manganese-containing wastewater is 1m 3 / h(5.5g / L Mn), the flow rate of adding alkali is 0.15m 3 / h(125g / LNaOH), CO 2 The concentration is 11%, the manganese-containing wastewater, lye, CO 2 Add from the upper end of the swirl bubble tower three-phase reaction device, swirl upward through the bottom, adjust the pH through the pH control system to maintain it above 6.85, and the manganese carbonate content of the precipitate obtained after precipitation and drying of the swirl three-phase reaction device (calculated as Mn) is 41.9%, which meets the qualified product requirements of "HGT 4203-2011 Industrial Manganese Carbonate", the concentration of Mn in the effluent is 0.0383g / L, and the recovery rate of manganese is 99.30%.

Embodiment 2

[0048] Continuous water intake is adopted, and the flow rate of manganese-containing wastewater is 1.1m 3 / h(4.8g / L Mn), the flow rate of adding alkali is 0.16m 3 / h(125g / LNaOH), CO 2 The concentration is 12%, the manganese-containing wastewater, lye, CO 2 Add from the upper end of the swirl bubble tower three-phase reaction device, swirl upward through the bottom, adjust the pH to maintain above 6.80 through the pH control system, and the manganese carbonate content of the precipitate obtained after precipitation and drying of the swirl three-phase reaction device (calculated as Mn) is 42.2%, which meets the requirements of qualified products in "HGT 4203-2011 Industrial Manganese Carbonate", the concentration of Mn in the effluent is 0.0152g / L, and the recovery rate of manganese is 99.68%.

Embodiment 3

[0050] Intermittent water intake is adopted, and 2.8m of manganese-containing wastewater is added at one time 3 (5.5g / L Mn), the amount of alkali added is 0.15m 3 (125g / LNaOH), CO 2 The concentration is 11%, the manganese-containing wastewater, lye, CO 2 Add from the upper end of the swirl bubble tower three-phase reaction device, swirl upward through the bottom, adjust the pH to maintain at 6.90 through the pH control system, react for 2 hours, and pass through the precipitation after the reaction of the swirl three-phase reaction device, and the precipitate obtained after drying The content of manganese carbonate (calculated as Mn) in the product is 42.9%, which meets the requirements of the first-class product in "HGT 4203-2011 Industrial Manganese Carbonate". The concentration of Mn in the effluent is 0.0131g / L, and the recovery rate of manganese is 99.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com