Method for synergistically removing silicon in tungsten smelting

A technology of silicon agent and tungsten ore, applied in the field of tungsten metallurgy, can solve the problem of high cost of silicon removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

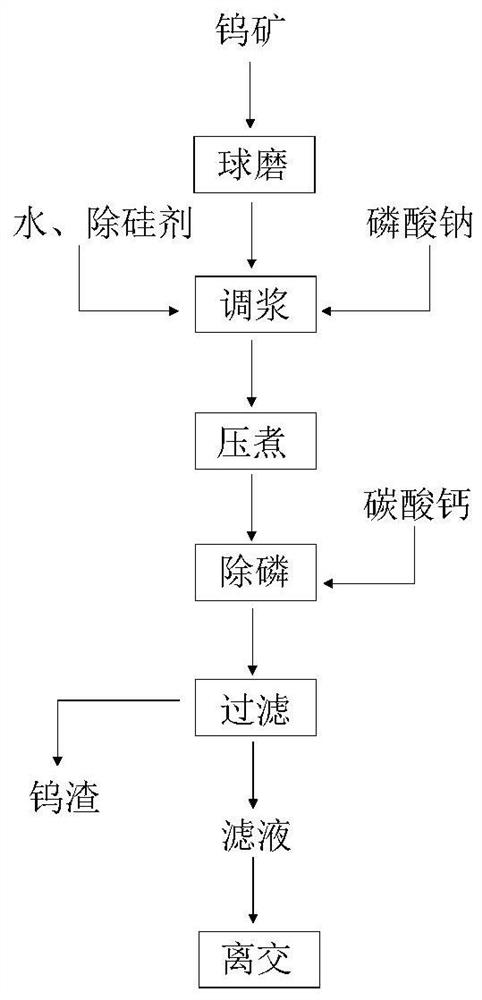

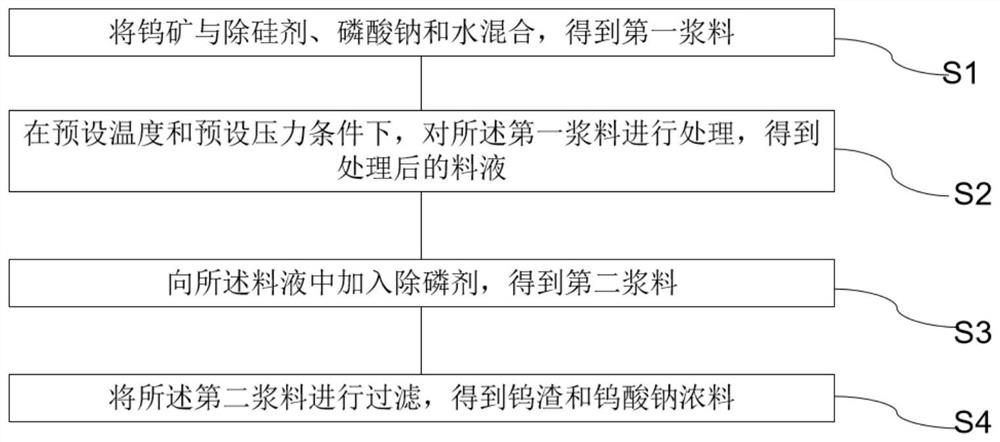

Method used

Image

Examples

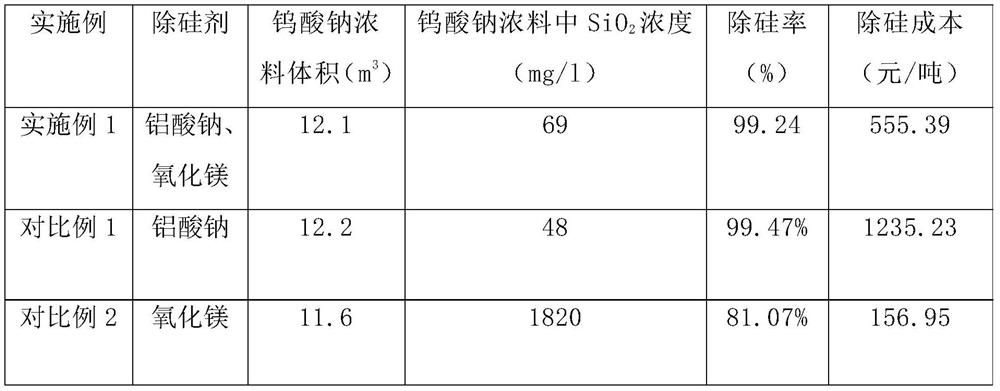

Embodiment 1

[0047] According to the method for synergistic silicon removal in tungsten smelting according to the embodiment of the present invention, the specific silicon removal process is as follows:

[0048] First, put 6.5m into the reaction tank 3 Water, turn on stirring, and add 0.45m in turn 3 Sodium aluminate solution (in which Al 3+ The concentration of 34.3g / l), 80kg of industrial grade magnesium oxide (MgO≥90%) and 1100kg of sodium phosphate, then put in 5000kg of tungsten ore, the tungsten ore WO 3 The content is 26.43wt%, SiO 2 The content of the powder was 2.23 wt %, and the obtained first slurry was fed to the autoclave after stirring sufficiently. The autoclave was heated with high-pressure steam, and the temperature was 170 °C and the pressure was 0.97 MPa for 1.5 hours of heat preservation and pressure retention. After discharging, calcium carbonate is added to the feed solution to remove phosphorus (the mass ratio of phosphorus content in the feed solution to calcium...

Embodiment 2

[0050] According to the method for synergistic silicon removal in tungsten smelting according to the embodiment of the present invention, the specific silicon removal process is as follows:

[0051] First, put 6 m into the reaction tank 3 Water, turn on stirring, and add 0.45m in turn 3 Sodium aluminate solution (where A l3+ The concentration of 35.7g / l), 40kg of industrial grade magnesium oxide (MgO≥90%) and 1200kg of sodium phosphate, and then put in 5000kg of tungsten ore, the tungsten ore WO 3 The content is 29.59wt%, SiO 2 The content of the powder was 2.29 wt %, and the obtained first slurry was fed to the autoclave after stirring sufficiently. The autoclave was heated with high-pressure steam, and the reaction was kept under pressure for 1.5 hours at a temperature of 175 °C and a pressure of 0.95 MPa. After discharging, calcium carbonate is added to the feed solution to remove phosphorus (the mass ratio of phosphorus content in the feed solution to calcium carbonate...

Embodiment 3

[0053] According to the method for synergistic silicon removal in tungsten smelting according to the embodiment of the present invention, the specific silicon removal process is as follows:

[0054] First, put 7m into the reaction tank 3 Water, turn on stirring, and add 0.45m in turn 3 Sodium aluminate solution (in which Al 3+ The concentration of 38.7g / l), 20kg of industrial grade magnesium oxide (MgO≥90%) and 1250kg of sodium phosphate, and then put in 5000kg of tungsten ore, the tungsten ore WO 3 The content is 30.56wt%, SiO 2 The content of the powder was 2.20 wt %, and the obtained first slurry was fed to the autoclave after stirring sufficiently. The autoclave was heated with high-pressure steam, and the reaction was kept under pressure for 1.5 hours at a temperature of 173 °C and a pressure of 0.97 MPa. After discharging, calcium carbonate is added to the feed solution to remove phosphorus (the mass ratio of phosphorus content in the feed solution to calcium carbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com