Canned fruit sugar water filter

A technology of canned fruit and filter, which is applied in water/sewage treatment, multi-stage water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problem of affecting production efficiency, poor filtering effect, balance of water inlet pipe and water outlet pipe Not easy to grasp and other problems, to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

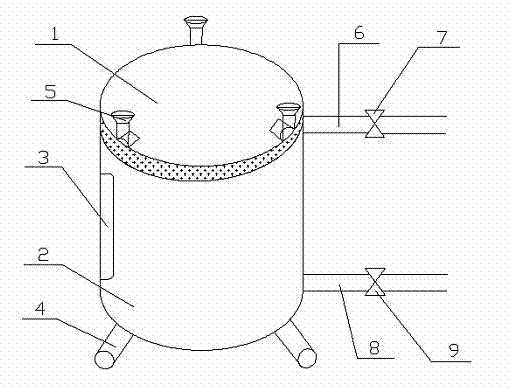

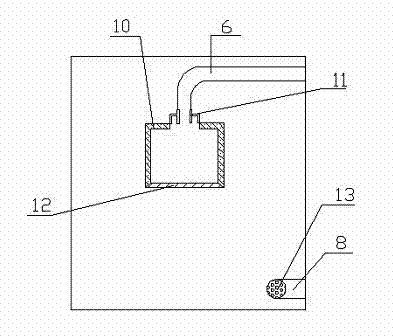

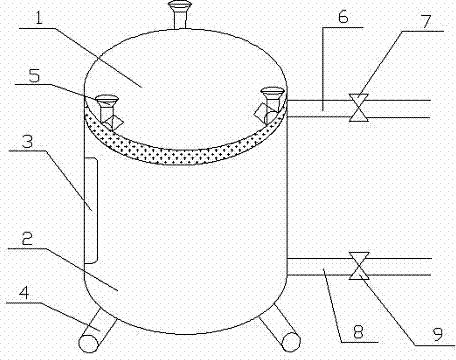

[0011] figure 1 , 2 The marks shown are as follows: cover 1, cylinder body 2, sight glass 3, support 4, bolt 5, water inlet pipe 6, water inlet pipe regulating valve 7, water outlet pipe 8, water outlet pipe regulating valve 9, filter box 10, thread 11 , Activated carbon 12, spherical filter screen 13.

[0012] figure 1 The shown canned fruit sugar water filter comprises a cover 1, a cylinder body 2, a support 4, an inlet pipe 6, an outlet pipe 8, and a filter box 10. The cylinder body 2 is provided with three bolts 5, 3 The bolts 5 are distributed in an equilateral triangle. There are 3 concave holes on the cover 1, and the 3 concave holes correspond to the 3 bolts 5 respectively; the toughened glass viewing mirror 3 is arranged on the cylinder body 1; Set 3 supports 4 to support the filter; set the water inlet pipe 6 on the same side of the cylinder body 1, set the water inlet pipe regulating valve 7 on the water inlet pipe 6, set the water outlet pipe 8 below, and set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com